System for determining sensor condition

a sensor condition and system technology, applied in the field of monitoring systems, can solve problems such as and the problems of both customers and service providers, and affecting the productivity, profitability and customer satisfaction of customers, and achieving the effect of improving the efficiency of the system

Active Publication Date: 2016-05-05

INTEL CORP

View PDF7 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

The present disclosure is about a system for monitoring sensors and determining if they are working properly. This system can be used in various applications, such as volume monitoring, to ensure that the sensors are providing accurate data. By analyzing the sensor signal and comparing it to pre-defined features, the system can determine if the sensor is functioning correctly or if there is an issue with the sensor itself. This helps to prevent issues with the process being monitored and ensures that the service provider is optimizing their resources and providing better service to the customer.

Problems solved by technology

The problem with this business model is that the customer is forced to wait for the required service, which may impact their productivity, profitability, and satisfaction with the service provider.

However, when malfunctioning, volume sensors may cause issues for both customer and service provider.

Volume sensors that errantly report full or empty tank conditions may cause material shortage or waste overflow conditions at a customer, which may negatively impact productivity, profitability and customer satisfaction.

Moreover, without accurate volume level data the service provider is forced into a mode of operation where resources may be expended needlessly (e.g., trucks may be sent out when unneeded) or haphazardly (e.g., to service emergency customer requirements) that may impact the service provider's ability to service their customers reliably, profitability, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 2

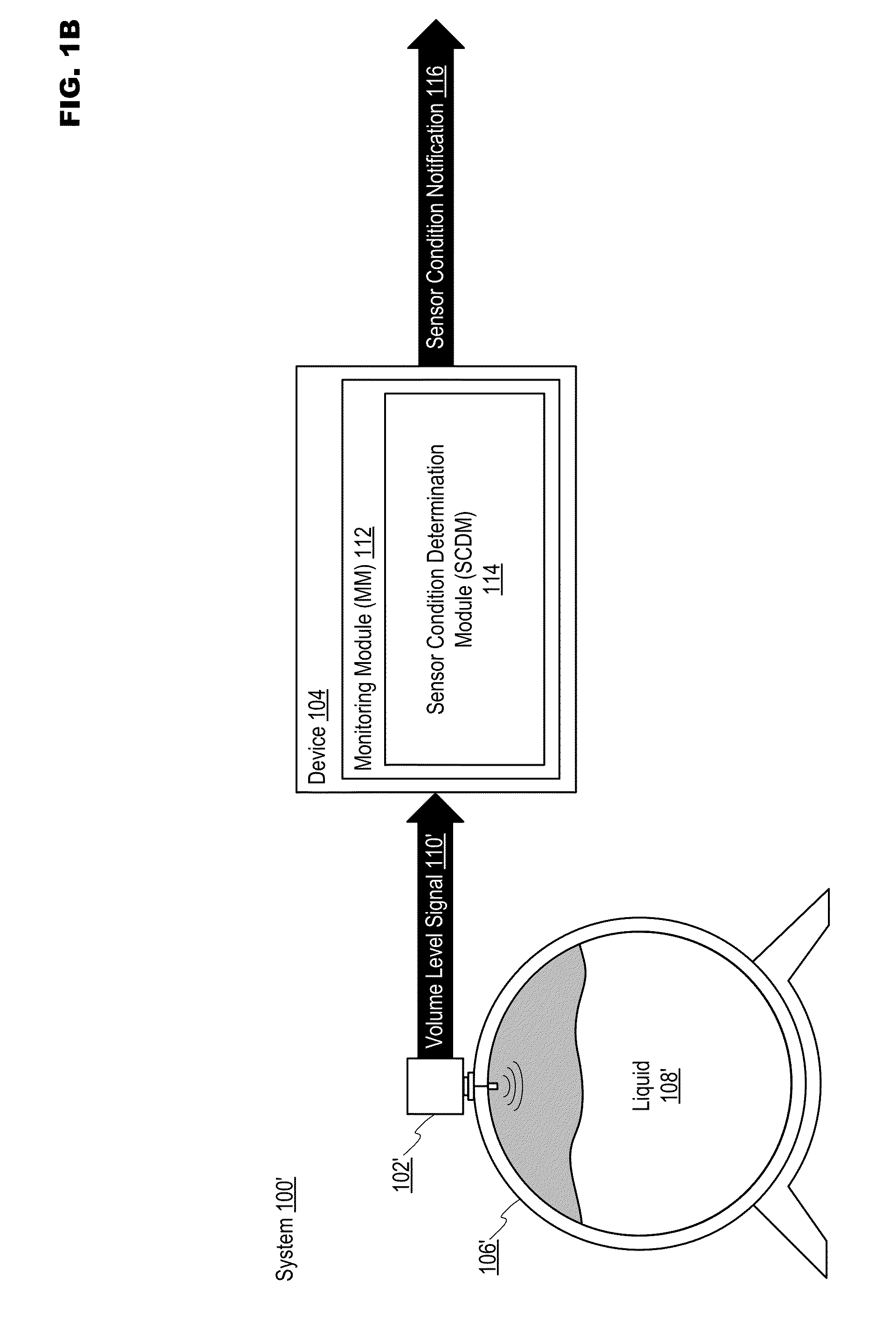

[0053 may include the elements of example 1, wherein the sensor is a volume sensor and the sensor signal is a volume level signal.

example 3

[0054 may include the elements of example 2, wherein the sensor is a tank level sensor and the sensor signal is a tank level signal.

example 4

[0055 may include the elements of any of examples 1 to 3, wherein the monitoring module is further to generate a sensor condition notification based on the condition.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

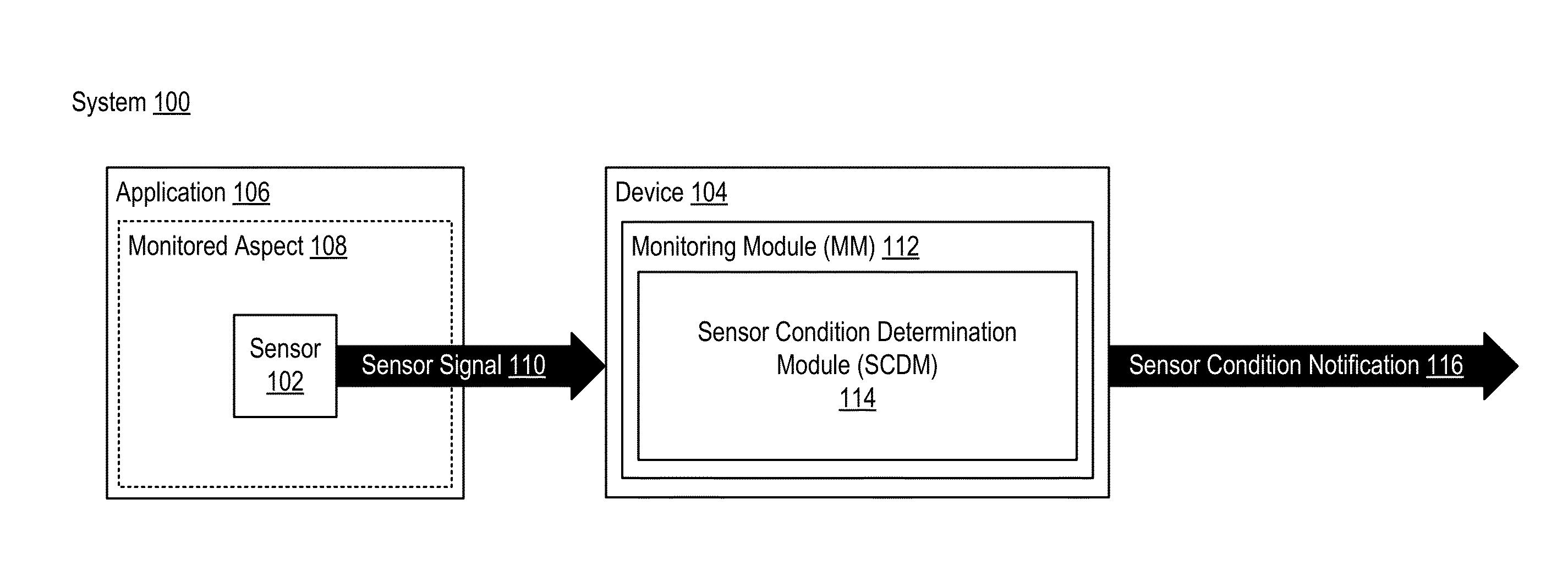

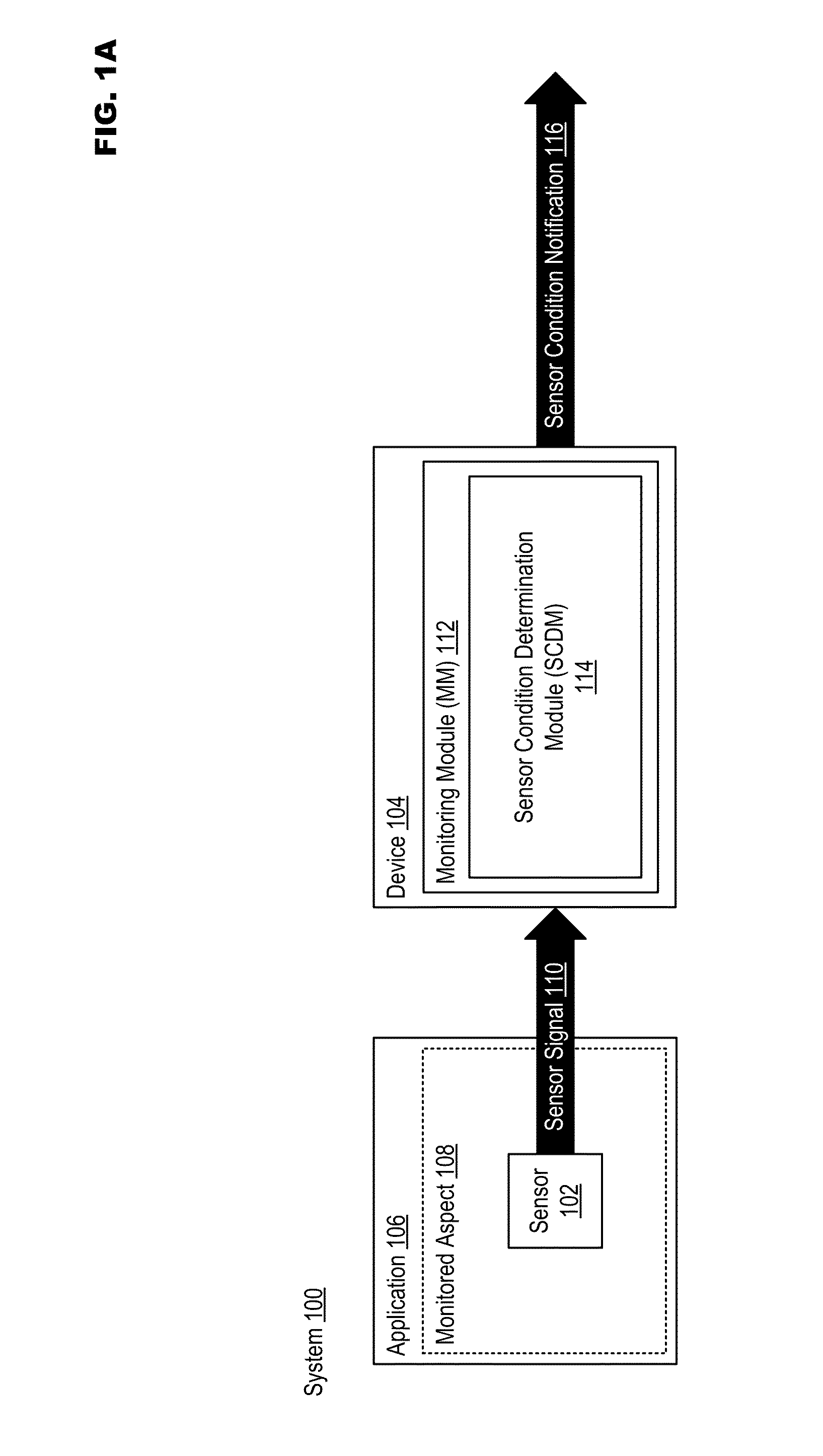

The present disclosure is directed to a system for determining sensor condition. A sensor signal generated by a sensor to communicate the current condition of an aspect being monitored by the sensor may also be employed to determine the condition of the sensor itself. For example, a device capable of determining if the sensor condition is normal or malfunctioning (e.g., erratic, stuck, etc.) may comprise a monitoring module (MM) to receive the sensor signal. The MM may comprise a sensor condition determination module (SCDM) to determine sensor condition. The SCDM may include a feature extraction engine to determine various characteristics of (e.g., to “extract features” from) the sensor signal and a model to determine sensor condition based on the extracted features. The model may include a support vector machine (SVM) taught to determine sensor condition utilizing sampled sensor signals correlated with annotations of sensor condition.

Description

TECHNICAL FIELD[0001]The present disclosure relates to monitoring systems, and more particularly, to a system for determining if a sensor is operating normally based only on a signal generated by the sensor.BACKGROUND[0002]Sensors may be employed in a variety of applications to provide feedback for controlling a process. For example, volume monitoring may be utilized to determine a volume of material in a vessel for emptying the vessel when filled, filling the vessel when empty, detecting leaks in the vessel, etc. Traditionally, when a vessel (e.g., a tank) required service (e.g., emptying or filling) a customer would request the required service from a service provider. The service provider may then schedule the required service based on workforce availability, material availability, routing efficiency, etc. The problem with this business model is that the customer is forced to wait for the required service, which may impact their productivity, profitability, and satisfaction with ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G08B21/18

CPCG08B21/187G08B25/08G01F25/0084G01F25/20G01F25/24

Inventor CHATTOPADHYAY, RITA

Owner INTEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com