Electronic cigarette and method for manufacturing electronic cigarette

a technology of electronic cigarettes and manufacturing methods, applied in the field of electronic cigarettes, can solve the problems of affecting the sealing effect, the inner space sealability of electronic cigarettes, and the mounting base of atomizers, and achieve the effect of enhancing sealability and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047]In combination with drawings, illustrative embodiments of the disclosure are below. The following explanation provides specific details for a thorough understanding of and enabling description for these embodiments.

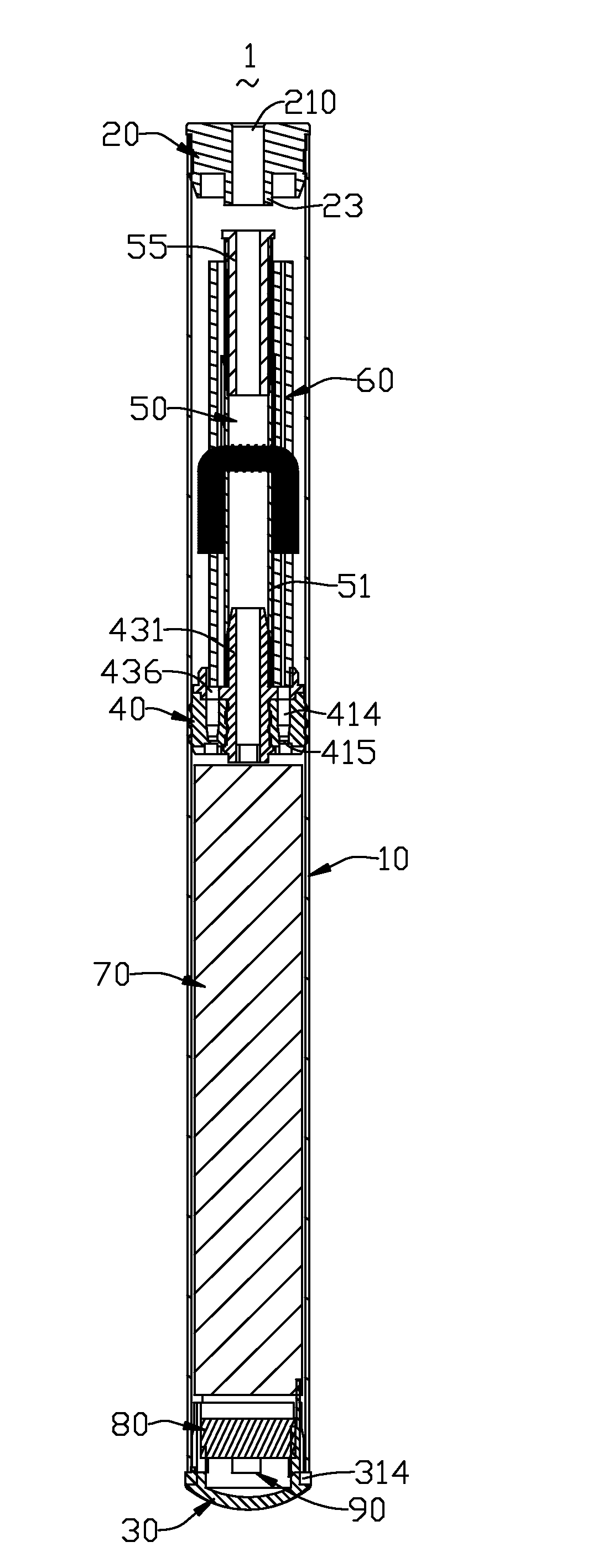

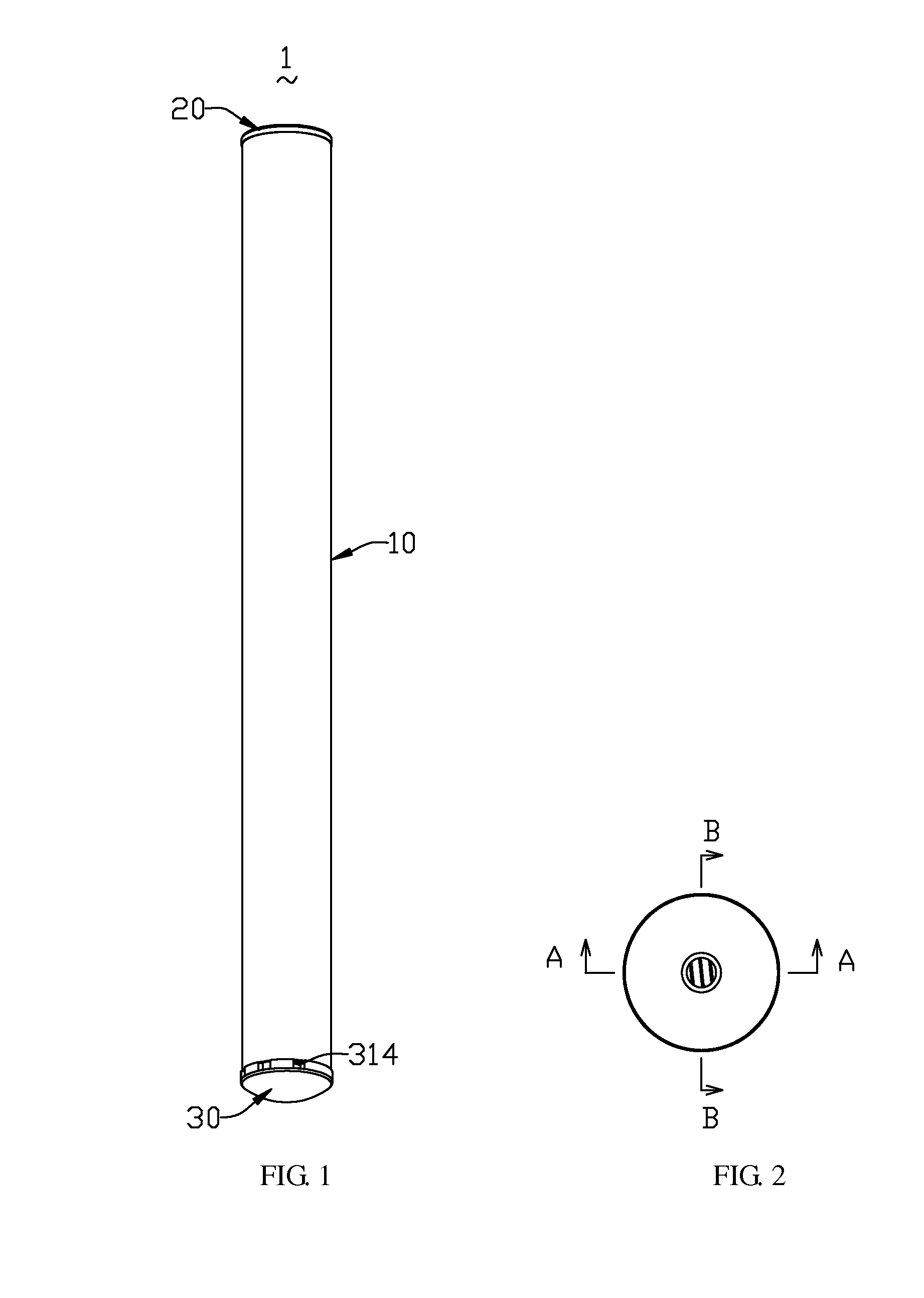

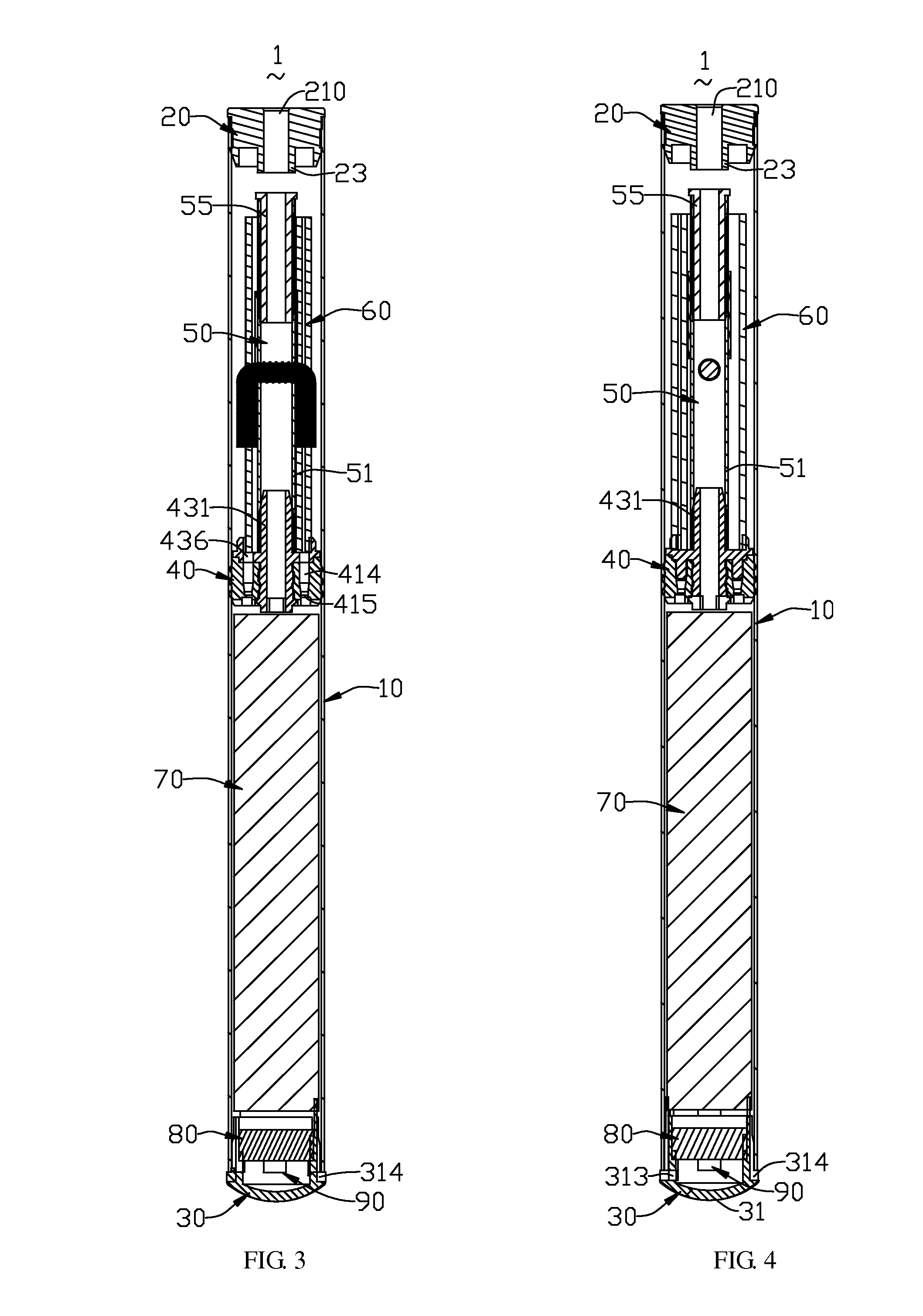

[0048]FIGS. 1-4, illustrate an electronic cigarette 1 in some embodiments. The electronic cigarette 1 may include a cylindrical housing 10, a mouthpiece 20, an end cover 30, an atomizer assembly mounting base 40, an atomizer assembly 50, a reservoir 60 for storing liquid solution, a power supply assembly 70, an air switch 80, and a light emitting unit 90.

[0049]The mouthpiece 20 and the end cover 30 are mounted to two opposite ends of the housing 10 respectively. The atomizer assembly mounting base 40, the atomizer assembly 50, the reservoir 60 and the power supply assembly 70 are disposed within the housing 10. The atomizer assembly mounting base 40 is arranged in the middle of the housing 10. The atomizer assembly 50 is mounted to the atomizer assembly mounting bas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic | aaaaa | aaaaa |

| external force | aaaaa | aaaaa |

| elastic body | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com