Method and Apparatus For Assembling Simulated Divided Light Window Grids

a divided light and grid technology, applied in the direction of building components, constructions, buildings, etc., can solve the problems of increasing the overall material and labor cost, increasing the fabrication cost and labor cost, and using improper muntin bars and divided light windows, so as to achieve easy and quick construction and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0002]1. Technical Field of the Invention

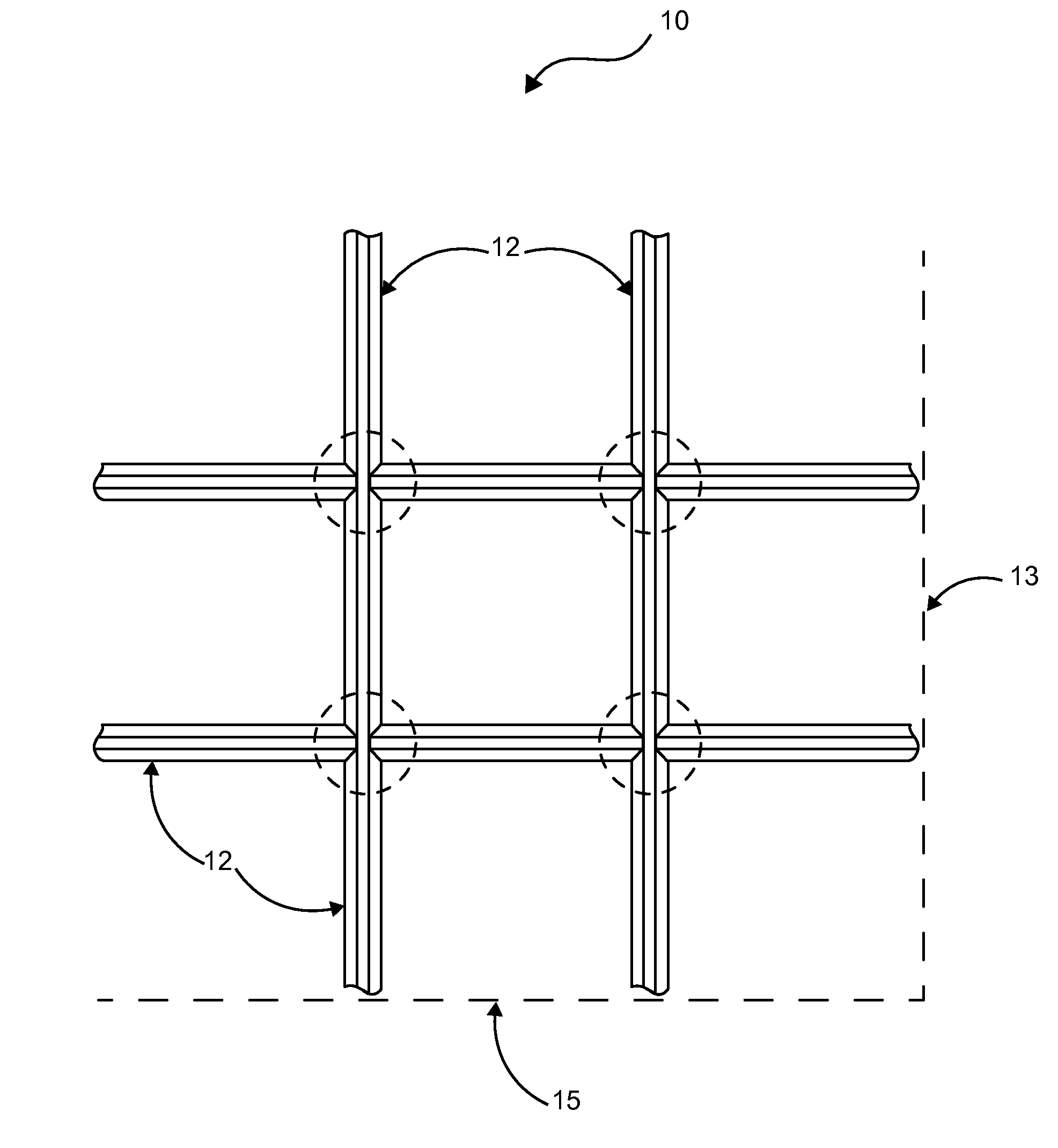

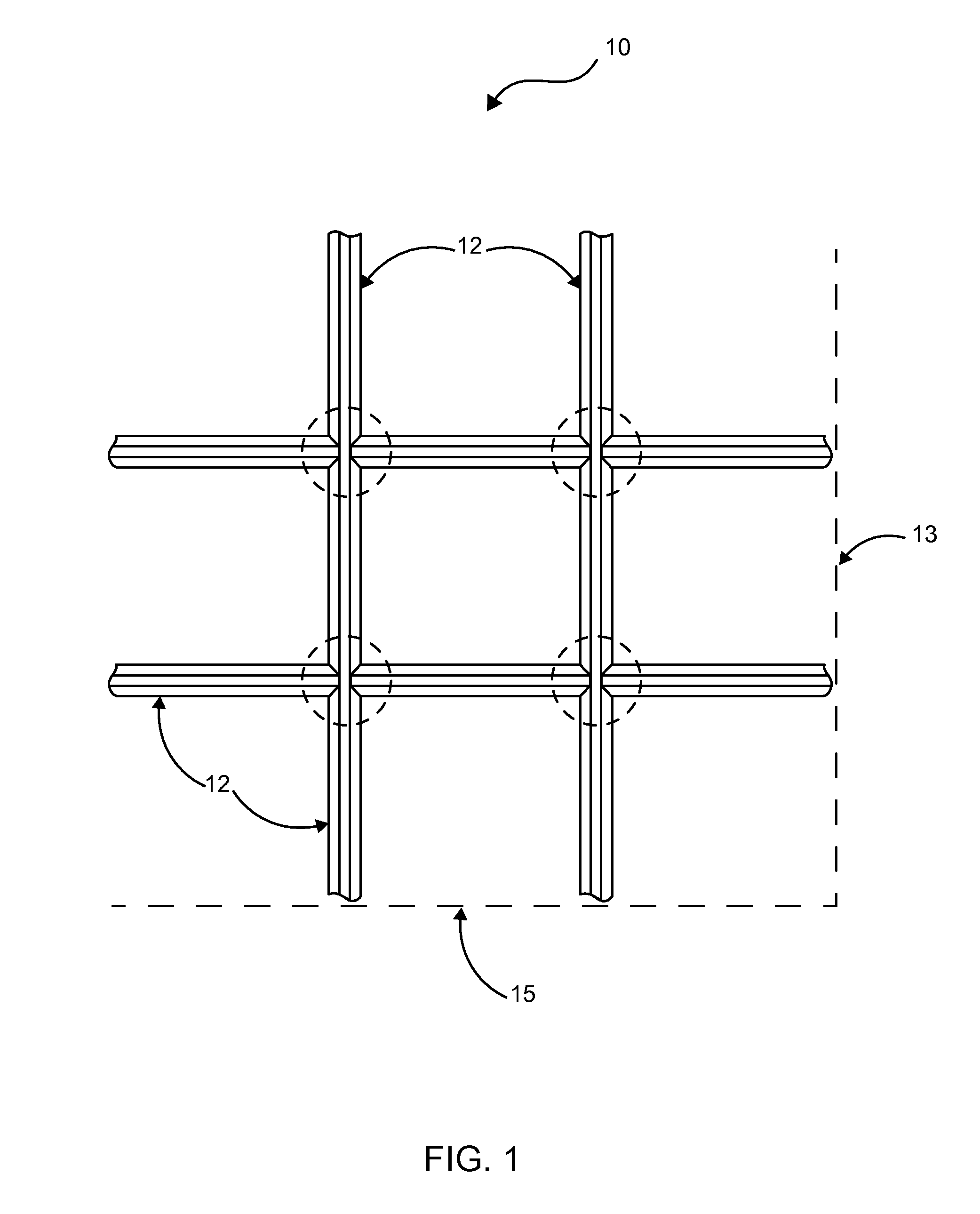

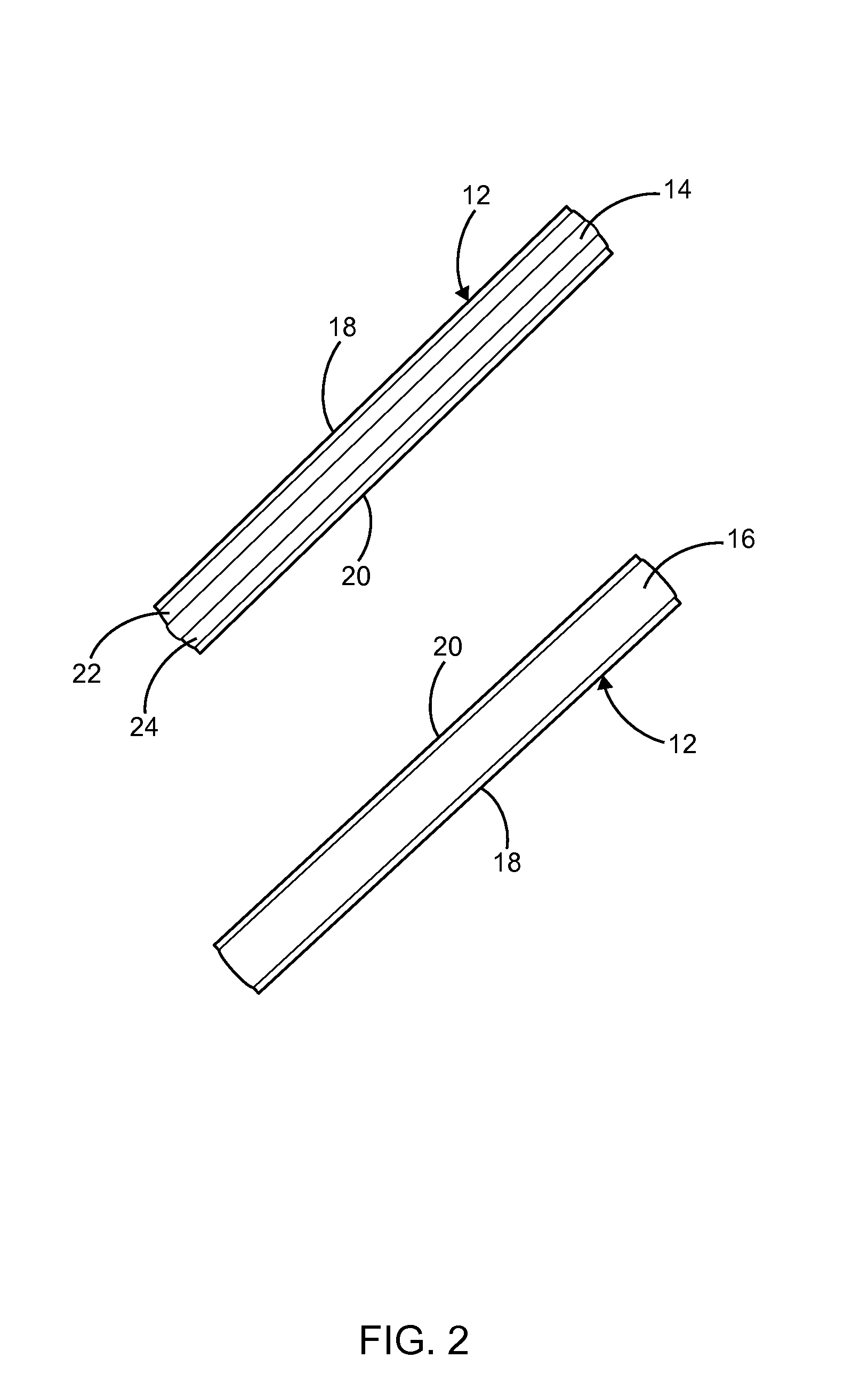

[0003]The present invention relates to a method and apparatus for assembling simulated divided light window grids. More specifically, the present invention relates to a method and tool for making repeatable assembly of simulated divided light window grids.

[0004]2. Description of the Related Art

[0005]In view of the constantly rising costs in the building materials industry, it has become increasingly important for builders and material suppliers to find fast and reliable methods and substitute materials to replace existing conventional materials and methods in order to effect economies in building construction without undue sacrifice in quality of construction and in the appearance of the finished product. The use of individual horizontal and vertical muntin bars and other window dividers provide good aesthetic feel, but the existing fabrication methods increases the overall material and labor cost. Increased fabricating costs and increased la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com