Modular and mobile waste and/or hazardous liquid containment and collection shower system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

, contained herein below, may be better understood when accompanied by a brief description of the drawings, wherein:

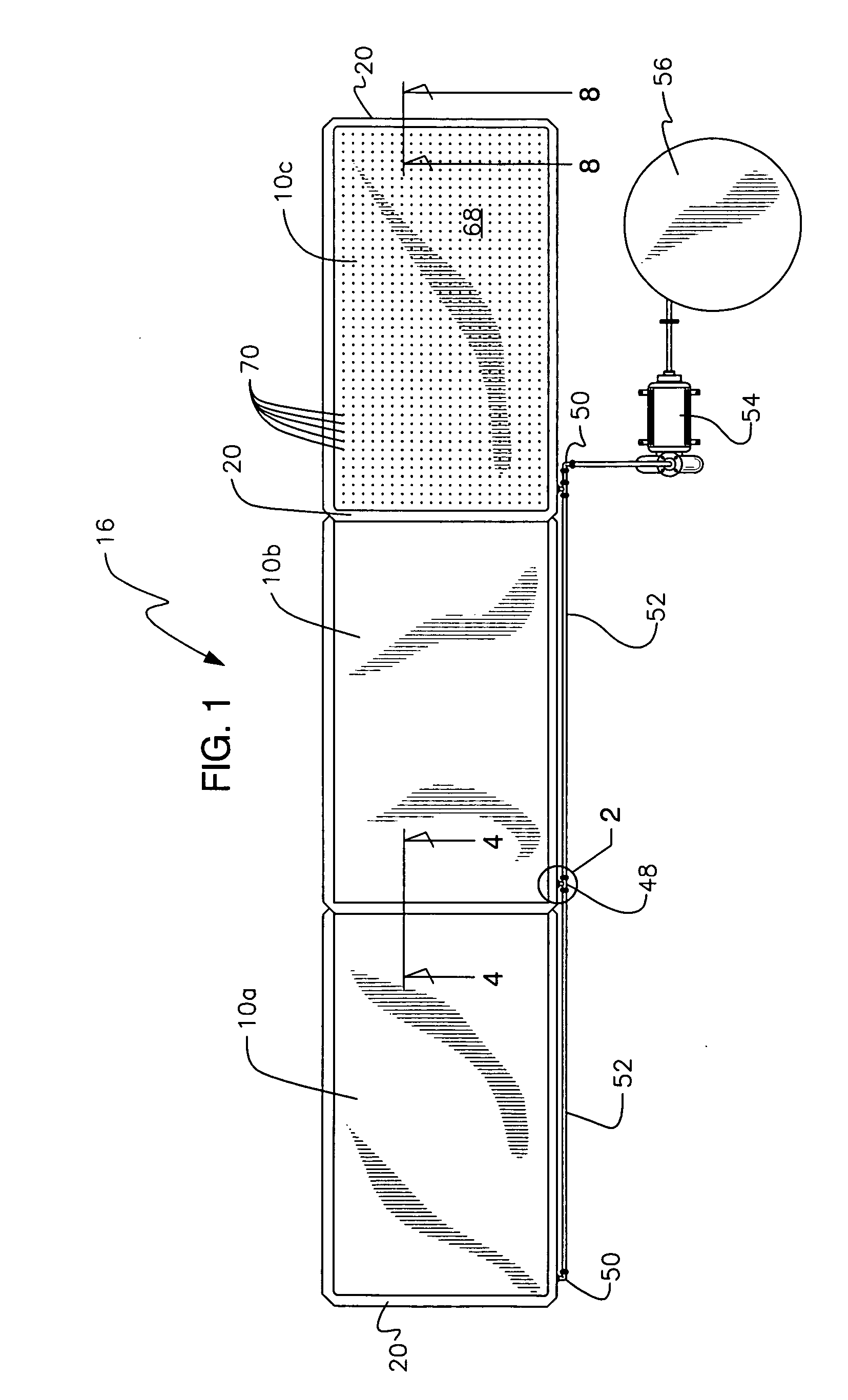

[0017]FIG. 1 is a top plan view of a hazardous and / or waste water collection and containment shower system of the present invention, illustrating the use of multiple modular pans or water impervious barriers;

[0018]FIG. 2 is a top plan view, partially in section, of a valve connection employed in any one of the modular pans employed in the present invention;

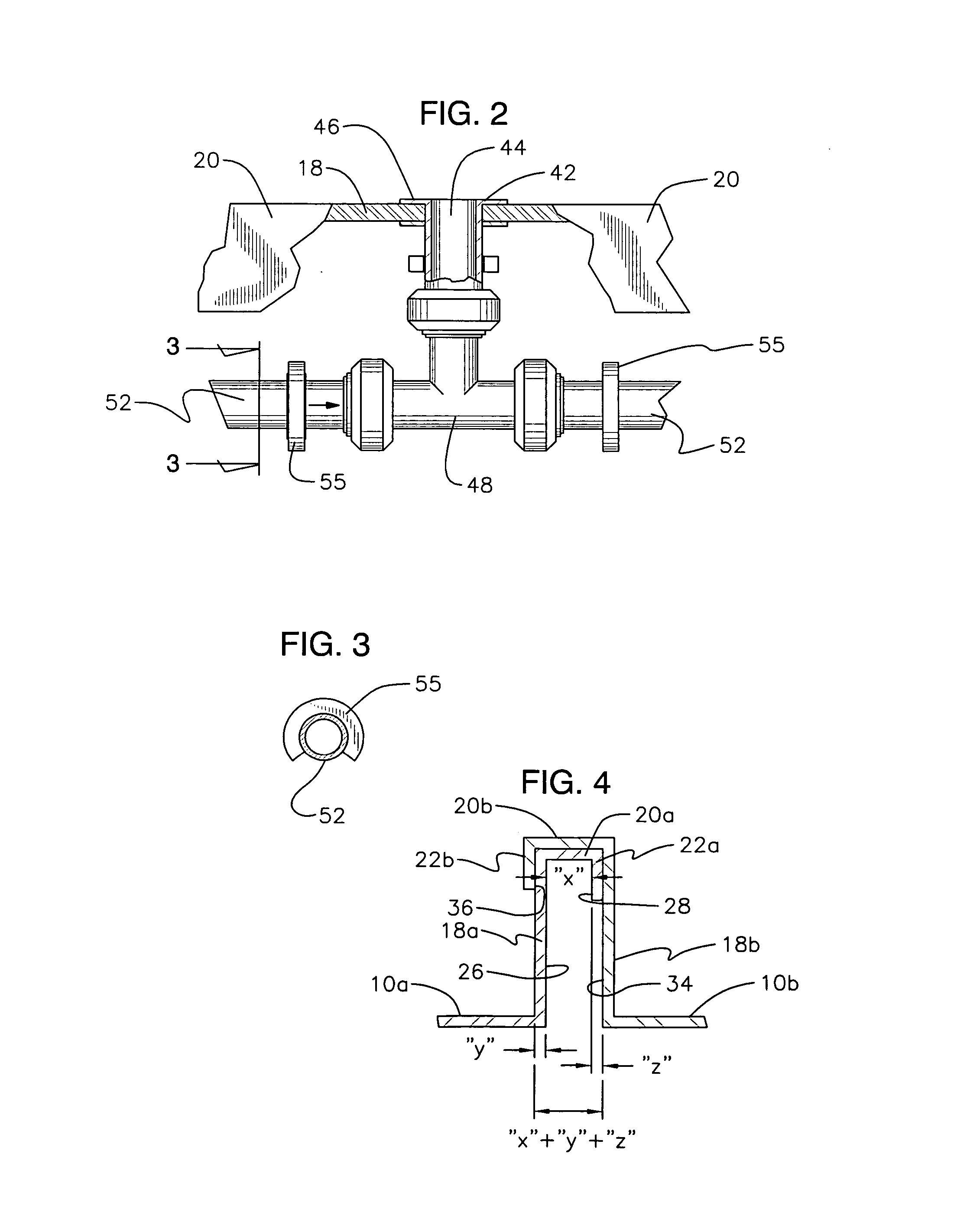

[0019]FIG. 3 is a cross section view of FIG. 2 along lines 3-3 of FIG. 2;

[0020]FIG. 4 is a cross-sectional view, along lines 4-4 of FIG. 1, illustrating how two modular pans interconnect by way of friction fit along top edges of upstanding walls thereof;

[0021]FIG. 5 is a perspective view of a corner section of a modular pan employed in the present invention;

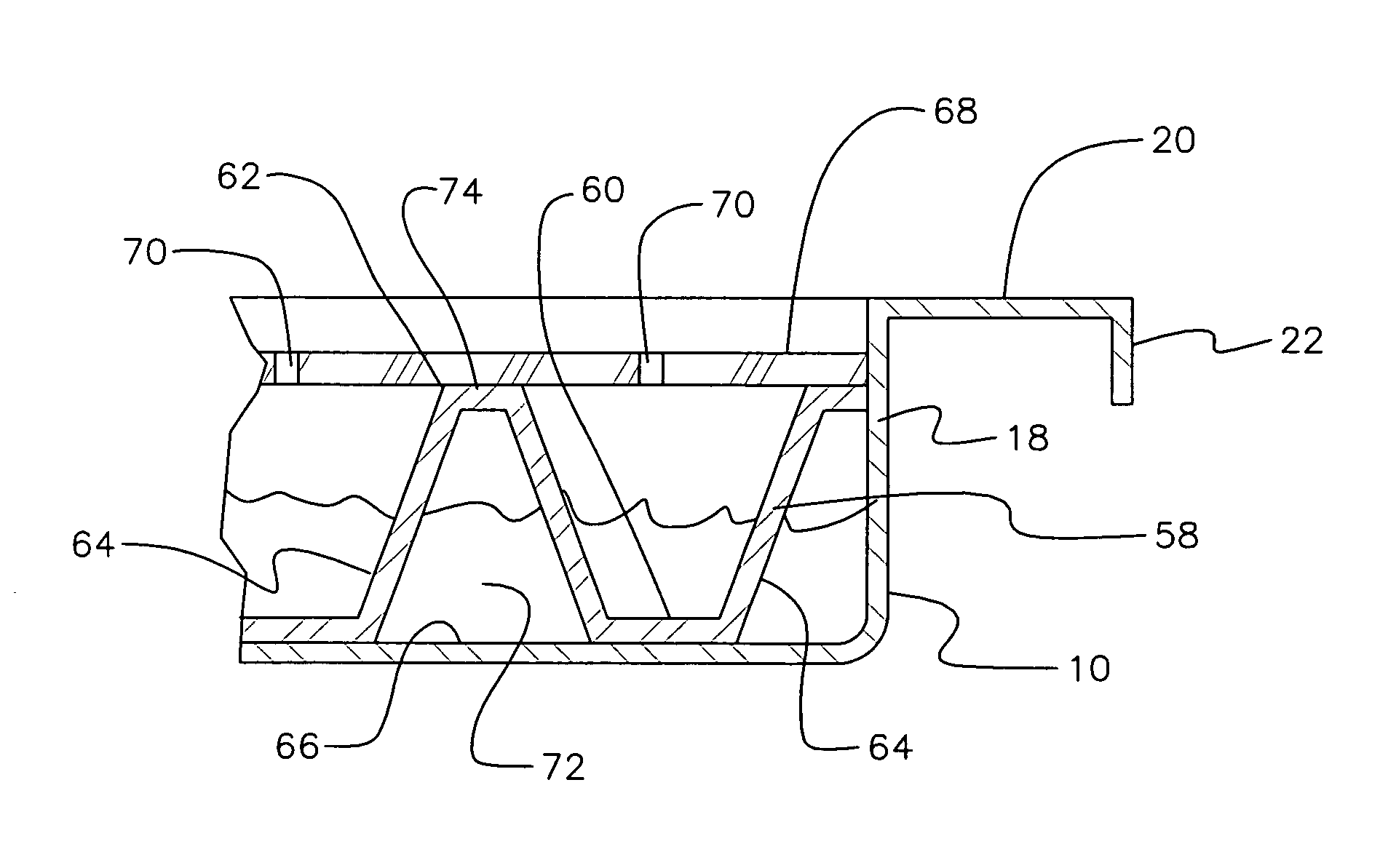

[0022]FIG. 6 is a side plan view, partially in section, of side edges of two modular pans illustrating the manner in which any two modular pans interconnect;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com