Shock absorbing structure and shoe to which the shock absorbing structure is applied

a technology of shock absorption and structure, applied in the field of shock absorption structure, can solve the problems of insufficient exposure of shock absorption material to the outside, insufficient ability to attract attention as a product, and inability to observe the state of soft materials from the outside, so as to achieve excellent shock absorption characteristic, enhanced shock absorption performance, and enhanced repulsive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiments

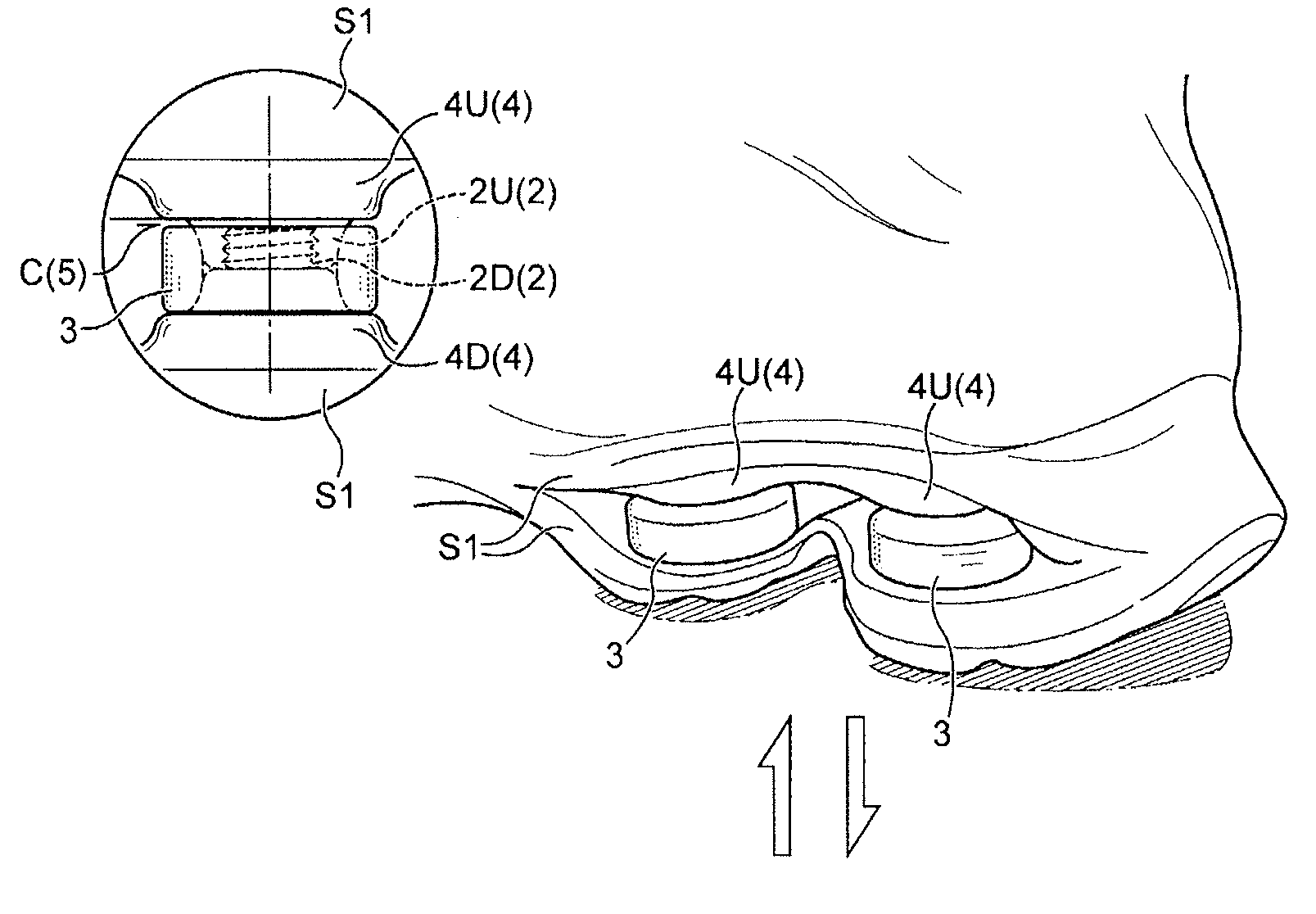

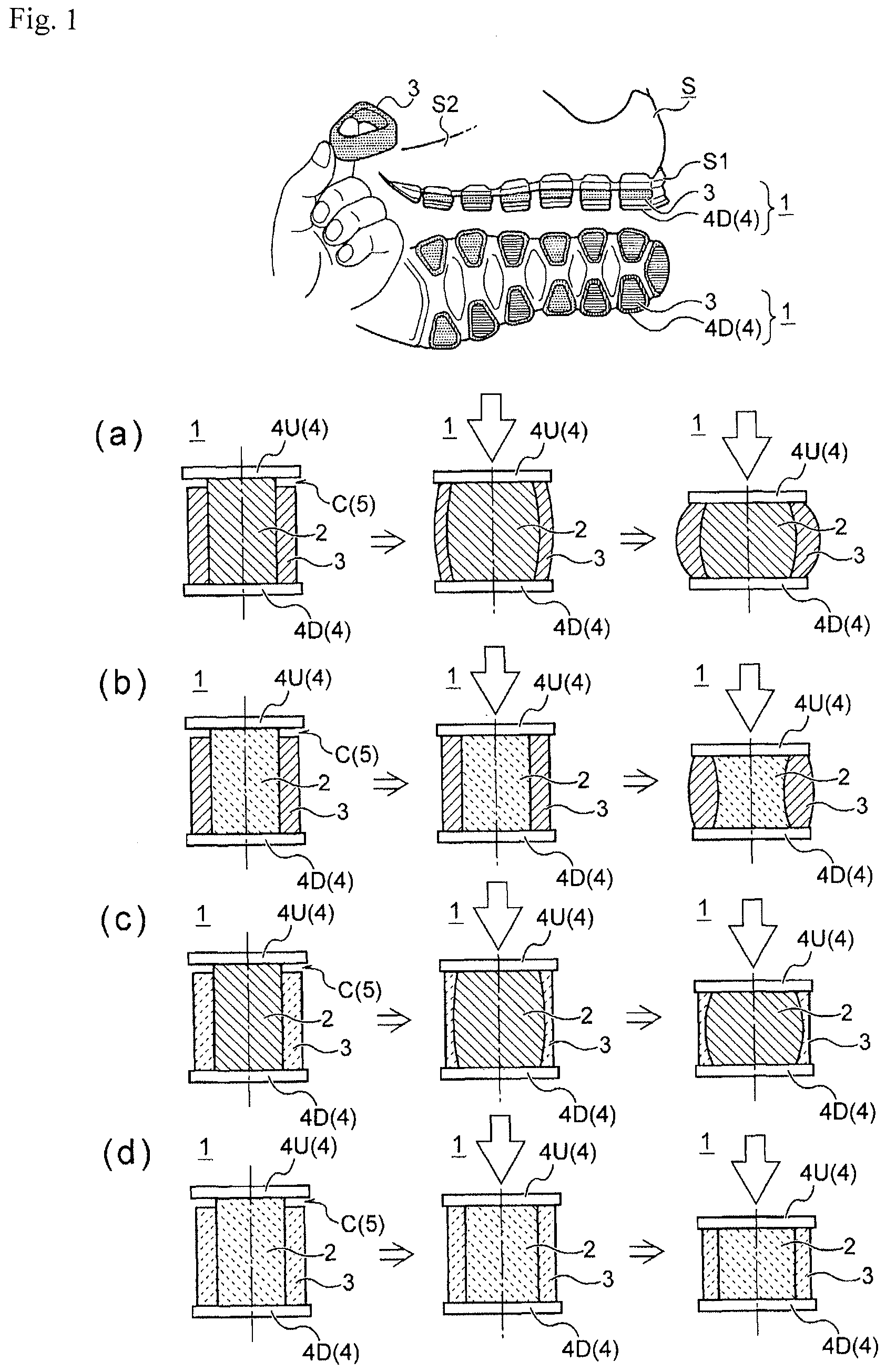

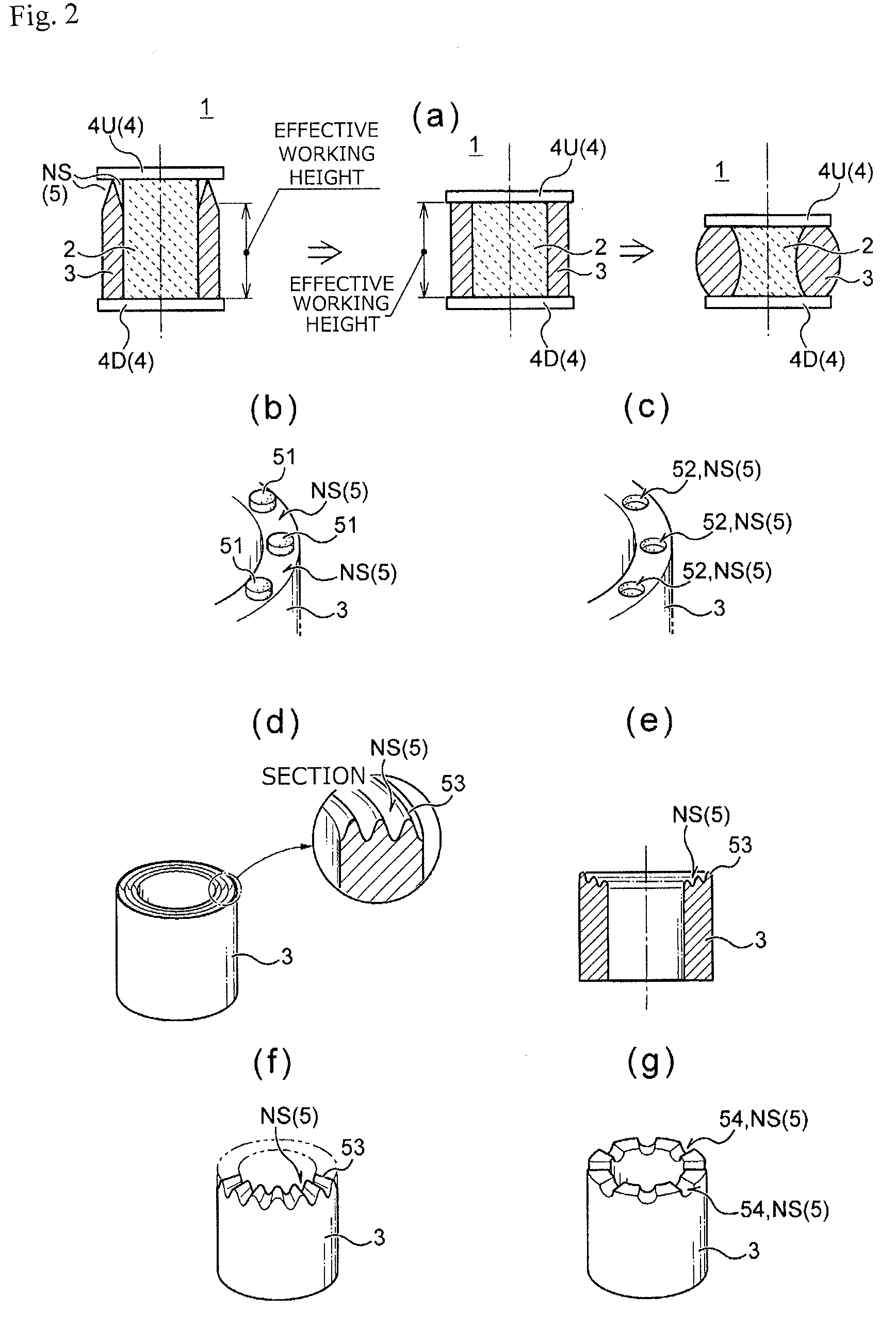

[0109]A shock absorbing structure 1 of the present invention is provided in footwear such as a shoe S, for example, as shown in FIG. 1 as an example, and the shock absorbing structure 1 absorbs impact that is applied to a leg of a person wearing (a wearer) the shoe S, and also enables a repulsive force to be smoothly converted into a kicking-out motion of a foot. Here, in the present embodiment, as a product in which the shock absorbing structure 1 is provided, a shoe (sport shoe) S is mainly shown, but as footwear other than this sandals and the like are cited, for example. The shock absorbing structure 1 of the present invention can be, as a matter of course, applied to products other than footwear, and are also applicable to supporters, protectors and the like which athletes wear to protect joints and the like, for example.

[0110]Hereinafter, the shoe S in which the shock absorbing structure 1 is provided will be described first.

[0111]The shoe S is formed by joining an upper S2 wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com