Anchor having a controlled driver orientation

a driver orientation and control technology, applied in the field of medical equipment and procedures for reconstructing ligaments, can solve the problems of limiting the surface area contact established between the graft ligament and the side wall, tearing or rupture of ligaments, and limiting the region

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056]The following description of the preferred embodiment(s) is merely exemplary in nature and is in no way intended to limit the disclosure, its application, or uses.

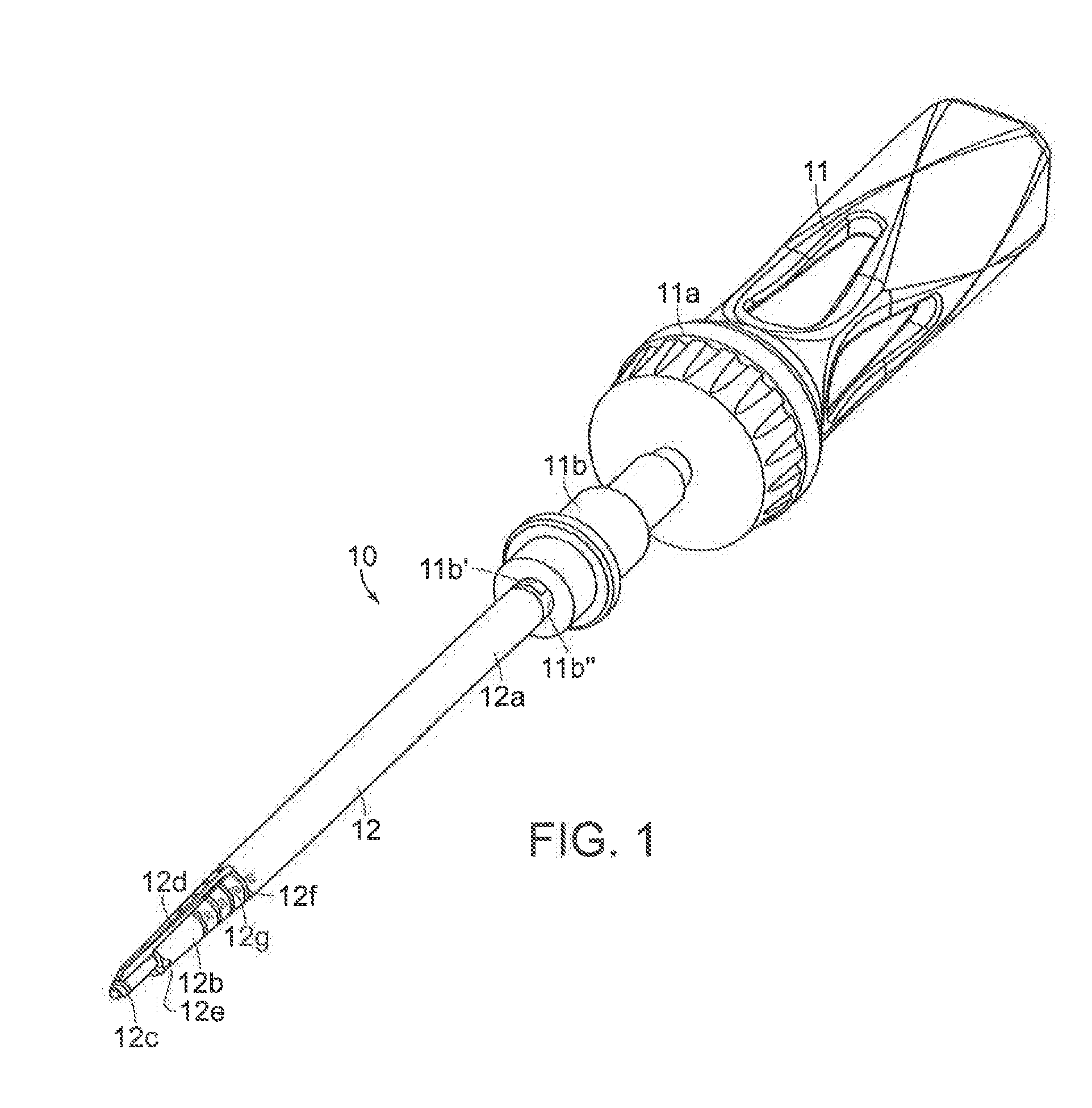

[0057]FIG. 1 shows a first embodiment of the delivery device 10 of the present disclosure. The device 10 includes a handle assembly 11 and a shaft 12 coupled to the handle assembly 11. The handle assembly 11 includes a handle 11a and a connector 11b coupled to the handle 11a. The connector 11b has a channel 11b′ and an opening 11b″ to the channel 11b′. The opening 11b″ is in the shape of a “D”. A proximal end 12a of the shaft 12 is disposed within the channel 11b′.

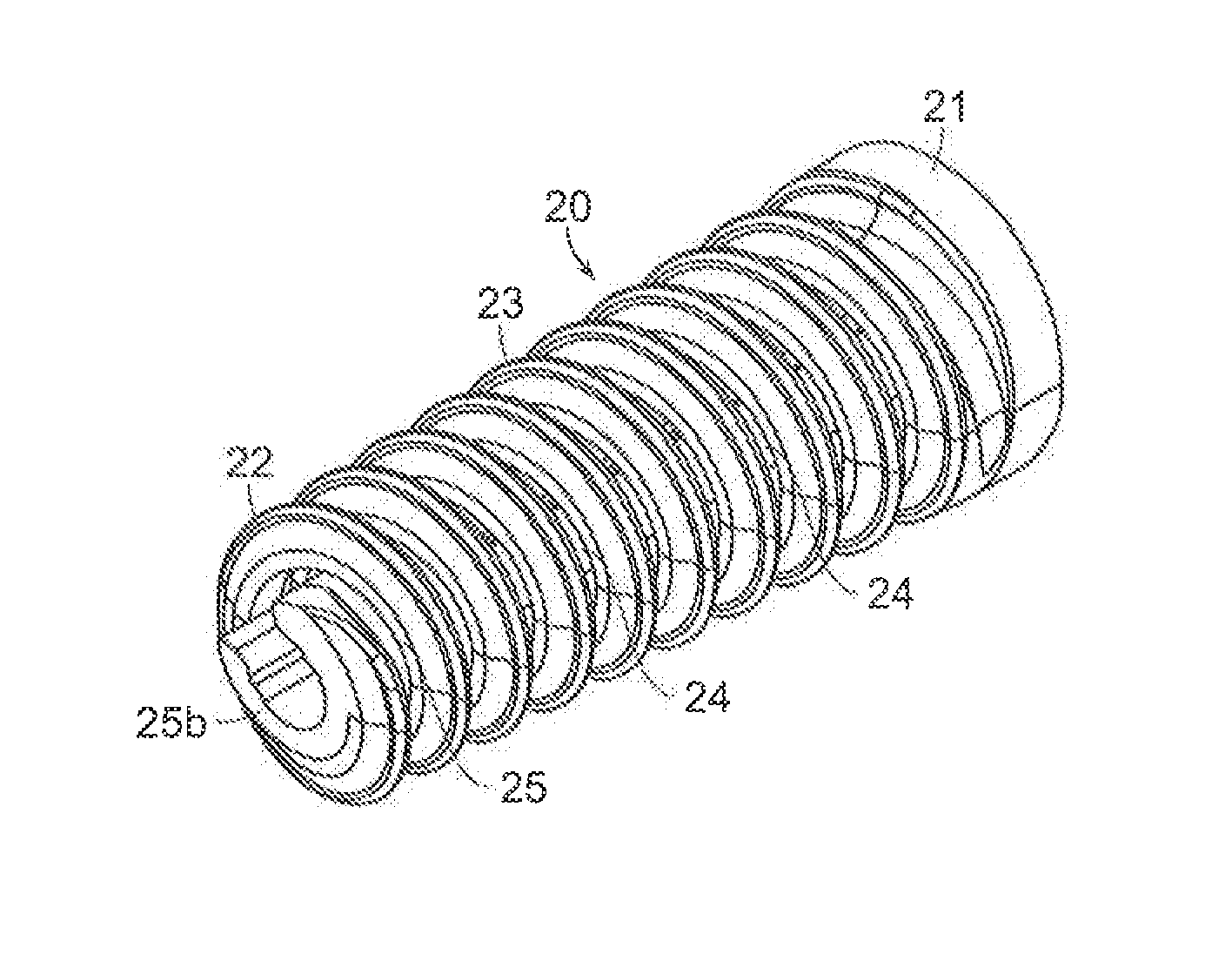

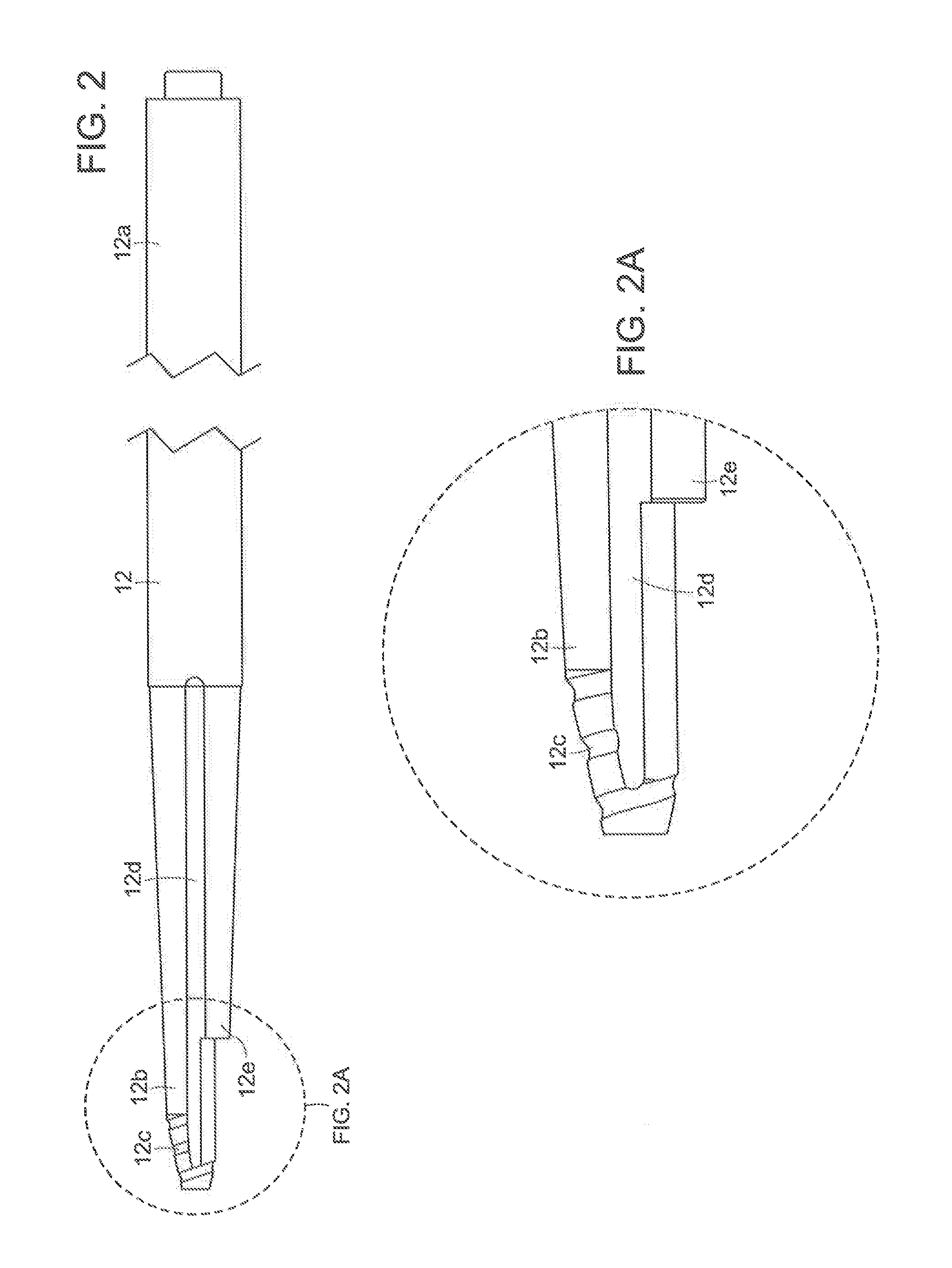

[0058]FIGS. 2, 2A, and 3-4 show the shaft 12. The shaft 12 includes a proximal end 12a and a distal end 12b. The proximal end 12a is in the shape of a “D” to match the shape of the opening 11b″. The distal end 12b includes threads 12c, grooves 12d, and a depth stop 12e. The grooves 12d extend a partial length of the shaft 12 and intersect the threads 12c. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com