Vehicle front structure

a front structure and vehicle technology, applied in the direction of roofs, transportation and packaging, vehicle arrangements, etc., can solve the problems of preventing the absorption of frontal impact load through the deformation of front side frames, and the front structures are not capable of absorbing frontal impact load, so as to facilitate the downward bending of the reinforcing member and improve the rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment

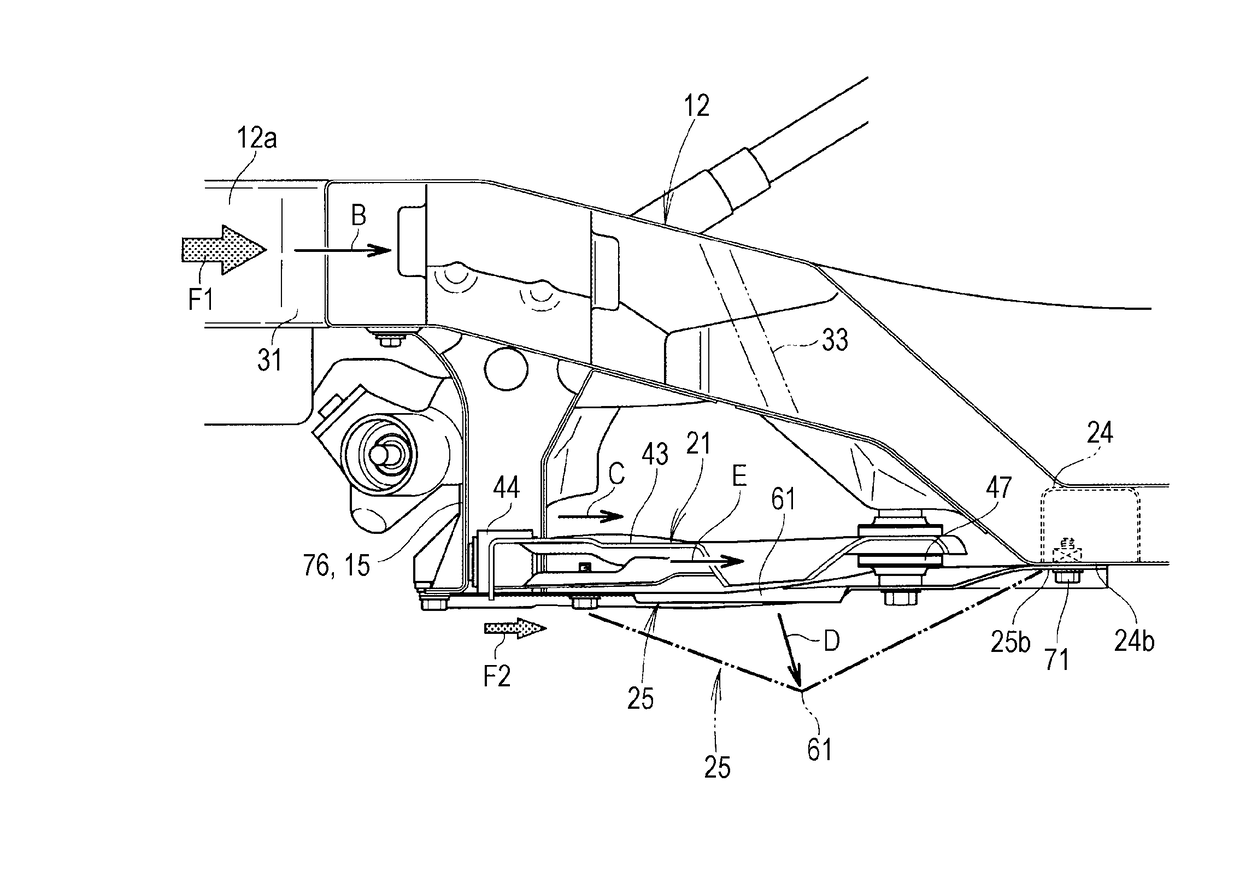

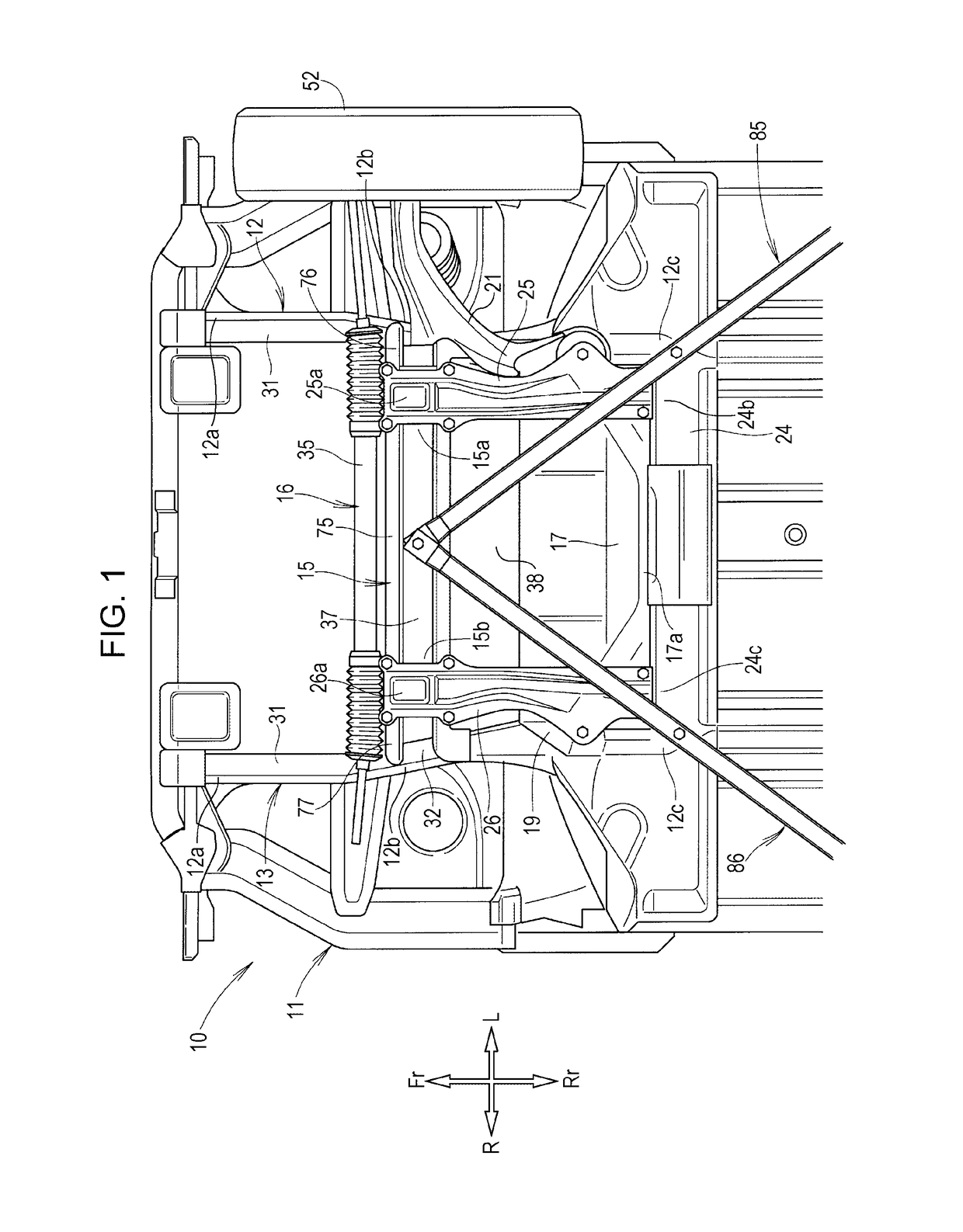

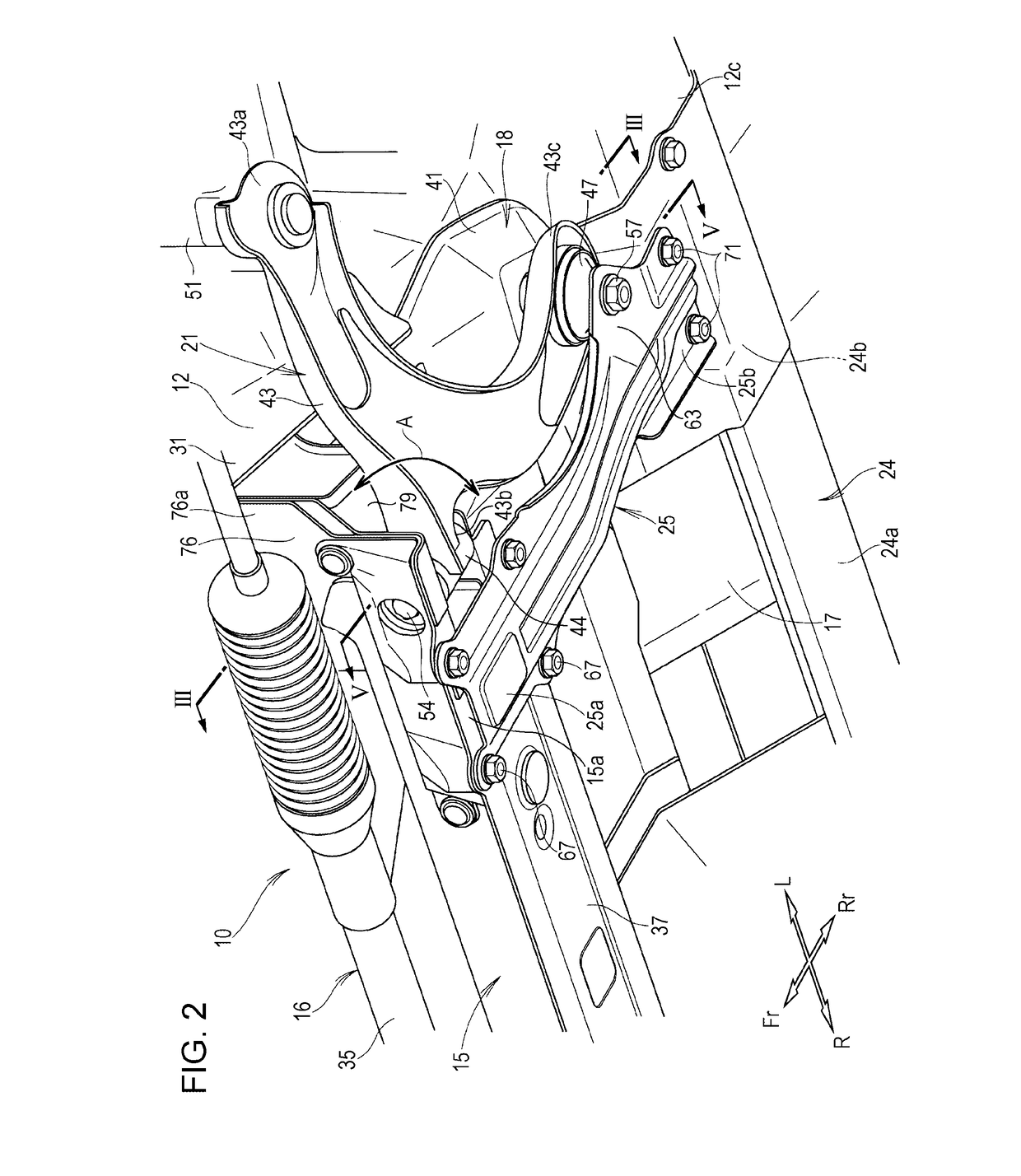

[0027]A vehicle front structure 10 according to an embodiment is described below. As illustrated in FIGS. 1 and 2, the vehicle front structure 10 has right and left front side frames 12 and 13 provided respectively on the right and left sides of a vehicle body 11, a cross member 15 installed across the right and left front side frames 12 and 13, and a power steering unit 16 provided along the cross member 15.

[0028]In addition, the vehicle front structure 10 has a dash panel 17 behind the cross member 15, a left mount 18 provided on the left front side frame 12 on the side of the dash panel 17, and a right mount 19 provided on the right front side frame 13 on the side of the dash panel 17.

[0029]Furthermore, the vehicle front structure 10 has a left suspension arm 21 supported by the cross member 15 and the left mount 18, a right suspension arm (not illustrated) supported by the cross member 15 and the right mount 19, a dash cross member 24 installed across the left front side frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com