Washing machine and liquid additive supply device for washing machine

a technology of liquid additive and washing machine, which is applied in the field of washing machines, can solve the problems of difficult pumping and supply of residual amount to the detergent supply device, difficult to move powder detergent upward, and difficult to use up the amount of detergent, so as to improve the use efficiency of liquid additive loaded and reduce the amount of unusable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

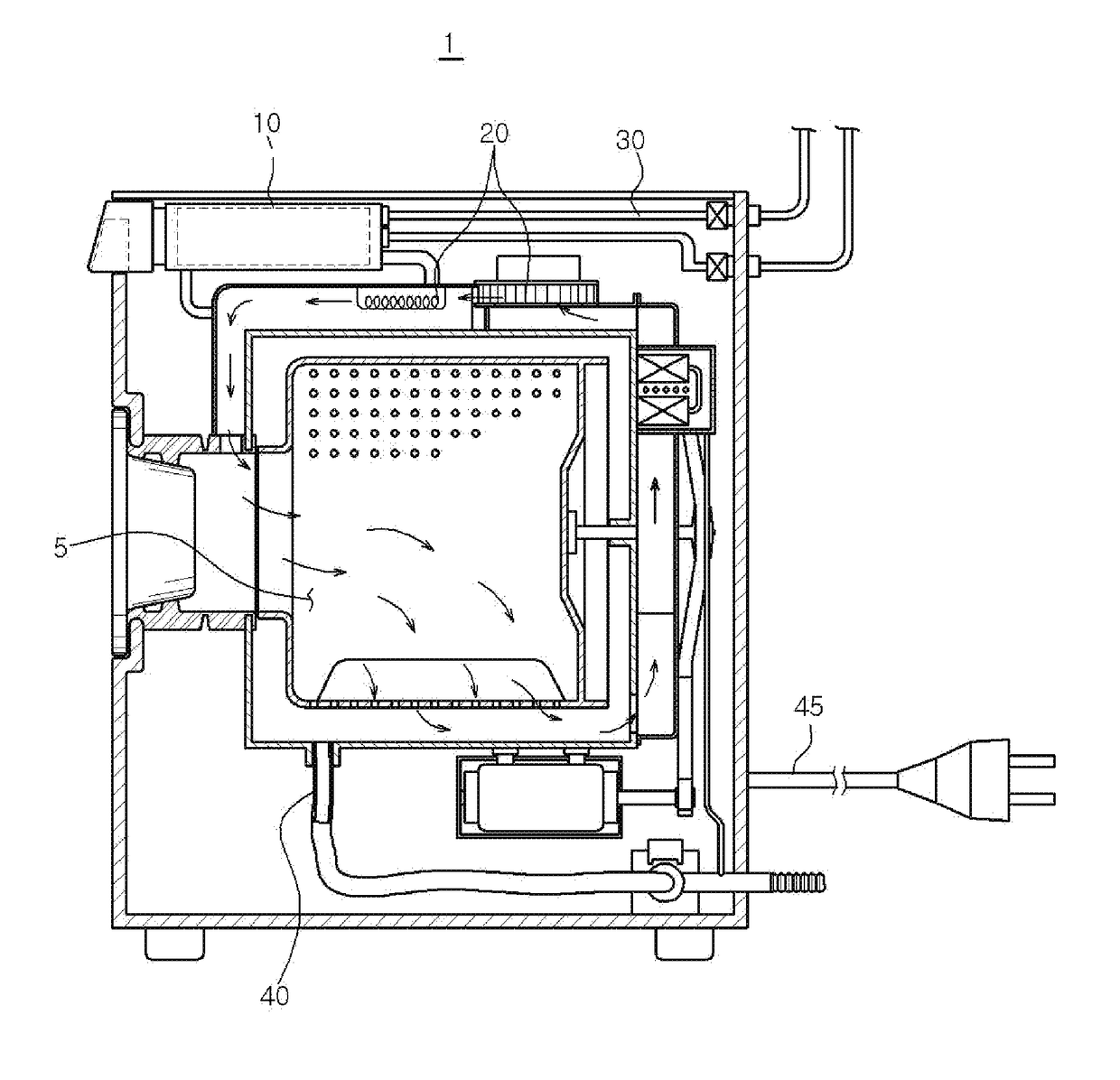

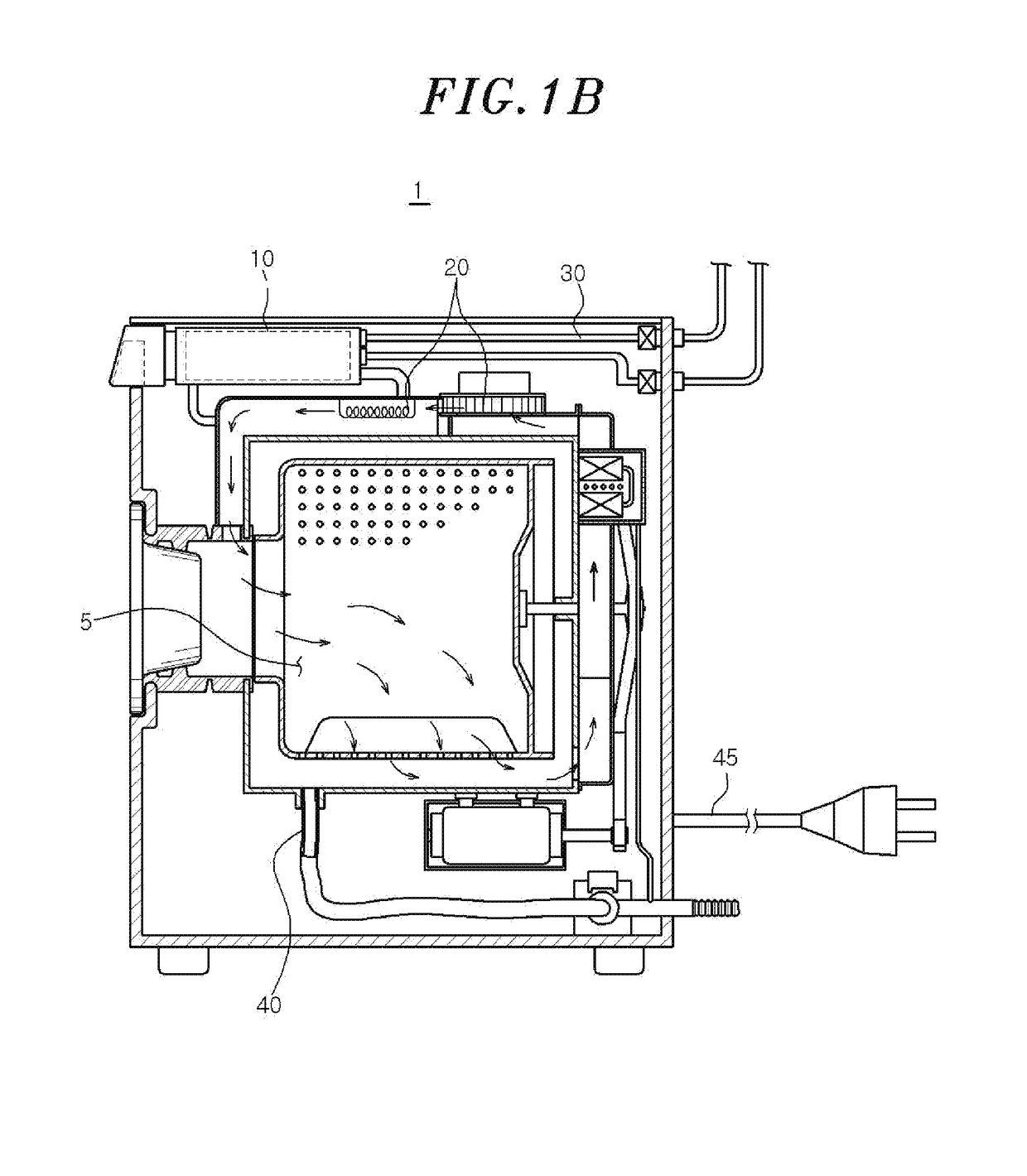

[0033]Hereinafter, configurations and operations of embodiments will be described in detail with reference to the accompanying drawings. The following description is one of various patentable aspects of the disclosure and may form a part of the detailed description of the disclosure.

[0034]However, in describing the disclosure, detailed descriptions of known configurations or functions that make the disclosure obscure may be omitted.

[0035]The disclosure may be variously modified and may include various embodiments. Specific embodiments will be exemplarily illustrated in the drawings and described in the detailed description of the embodiments. However, it should be understood that they are not intended to limit the disclosure to specific embodiments but rather to cover all modifications, similarities, and alternatives which are included in the spirit and scope of the disclosure.

[0036]The terms used herein, including ordinal numbers such as “first” and “second” may be used to describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com