Alignable Connector

a technology of alignable connectors and connectors, applied in the direction of drilling casings, drilling pipes, surveying, etc., can solve the problems of unreliable communication, difficulty in transmitting power, commands or information along the drill string or to and from the drill bit, and the inability to properly work the stab connector

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

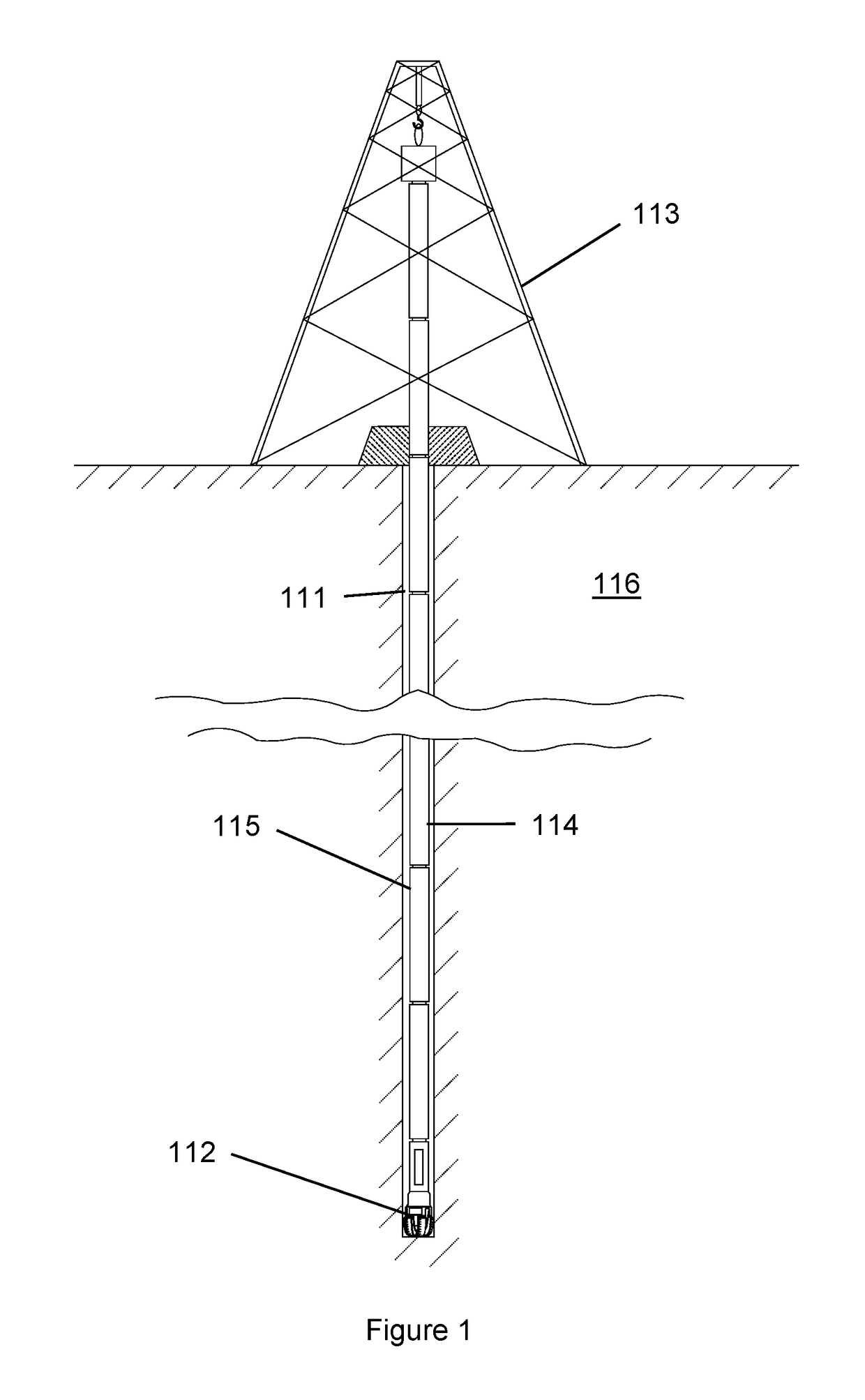

[0016]FIG. 1 shows an embodiment of a drilling operation comprising a drill bit 112 suspended from a derrick 113 by a drill string 114. The drill bit 112 may be rotated from the derrick 113 by a top drive, by a downhole motor disposed within the drill string 114, or by a combination of the two. As the drill bit 112 rotates it may engage and degrade an earthen formation 116 to form a borehole 111 therein. The drill bit 112 may be fed into the borehole 111 formed in the earthen formation 116 as the borehole 111 lengthens. Any of a variety of known downhole drill bits, such as a roller-cone bit or drag bit, may be used. Tools or other devices may be disposed at various locations along the drill string 114 to perform such tasks as controlling a rate of penetration of the drill bit or steering the drill bit towards an attractive destination. To gather information about the earthen formation 116 being drilled or the process of drilling as it progresses, any of a variety of sensors may be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com