Latch for a Ball and Sleeve Plunger

a technology of sleeve and ball, which is applied in the direction of fluid removal, borehole/well accessories, construction, etc., can solve the problems of ball to be unseated, and the wall of the sleeve being susceptible to premature failure, so as to facilitate the removal of the retaining ring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

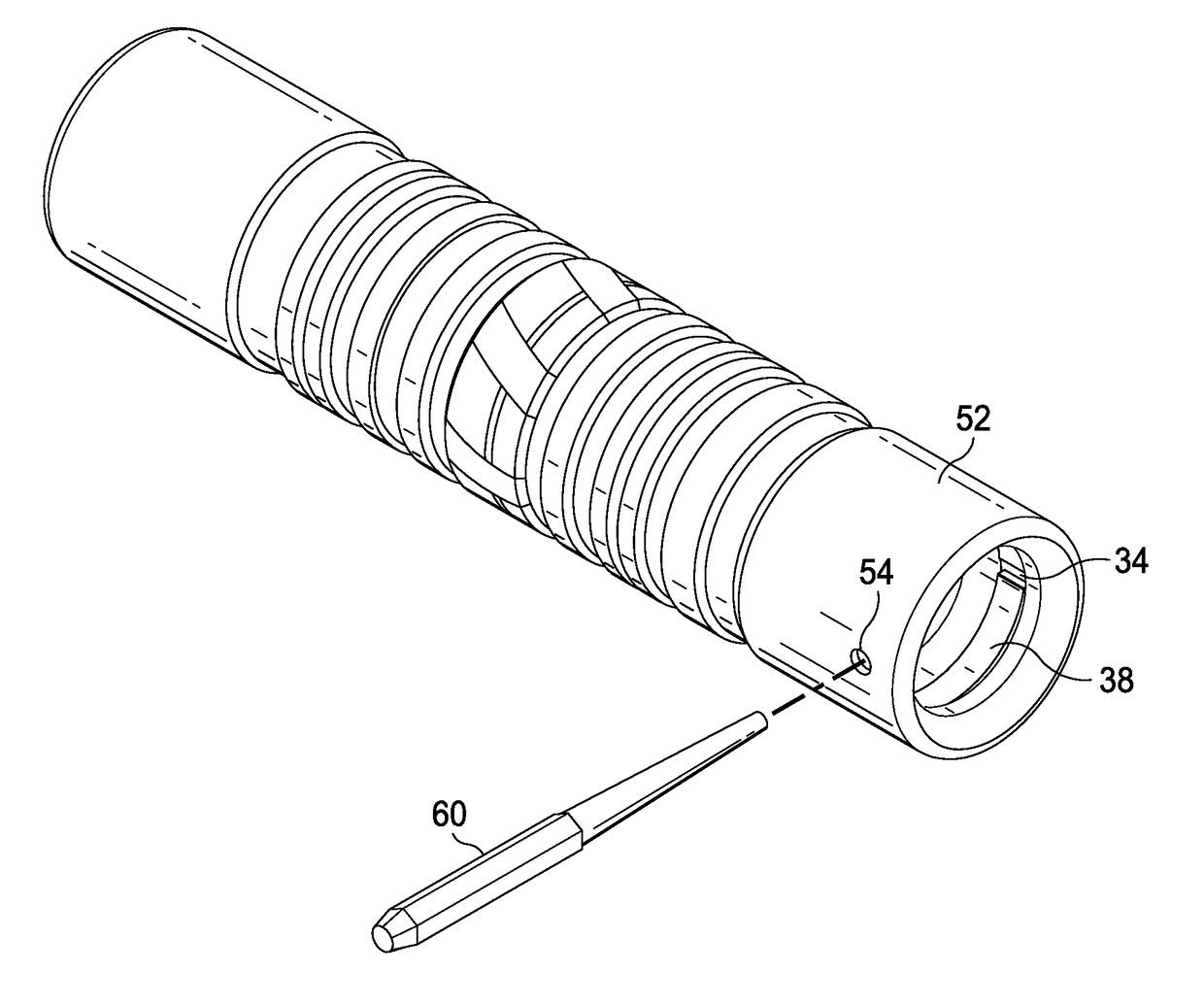

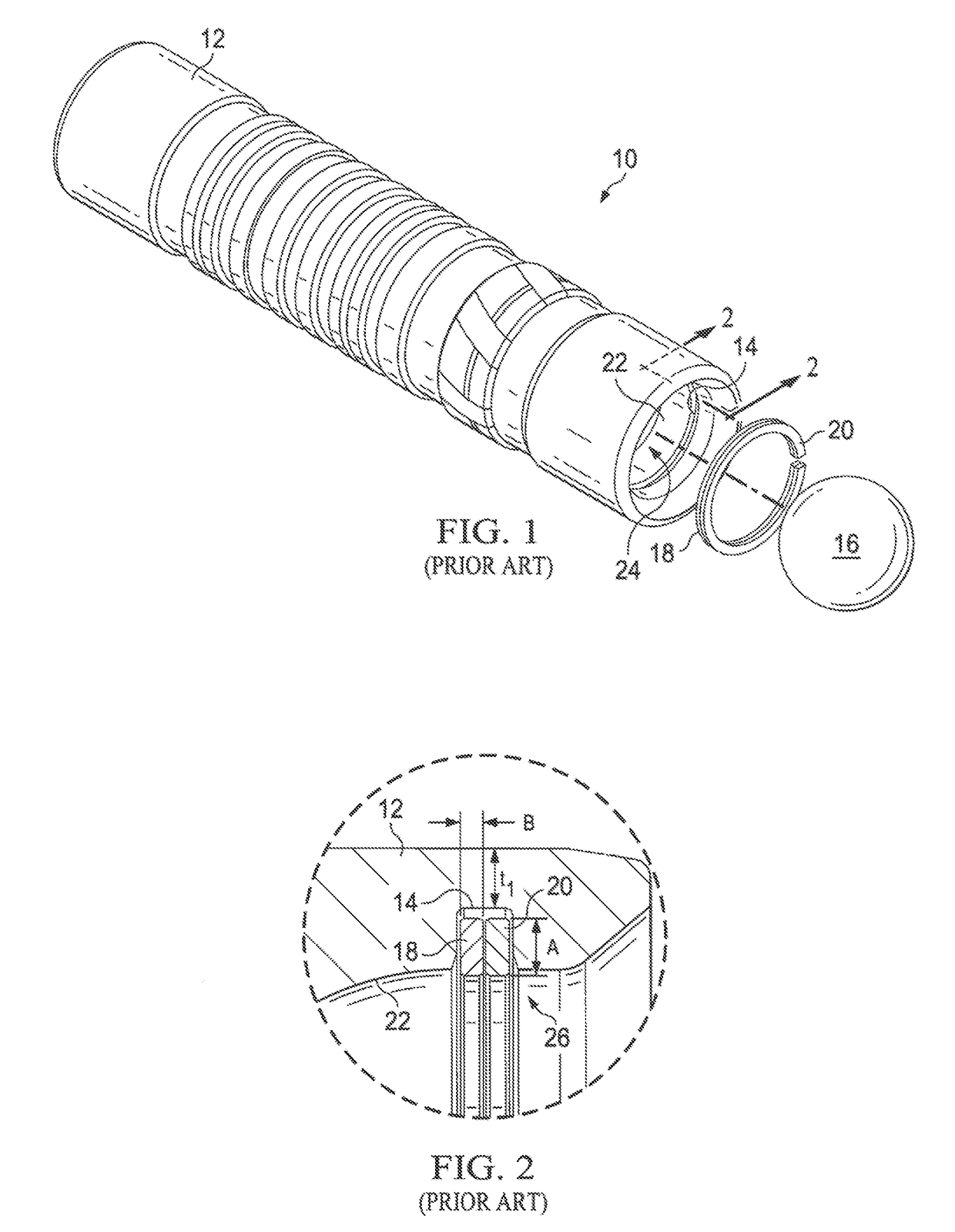

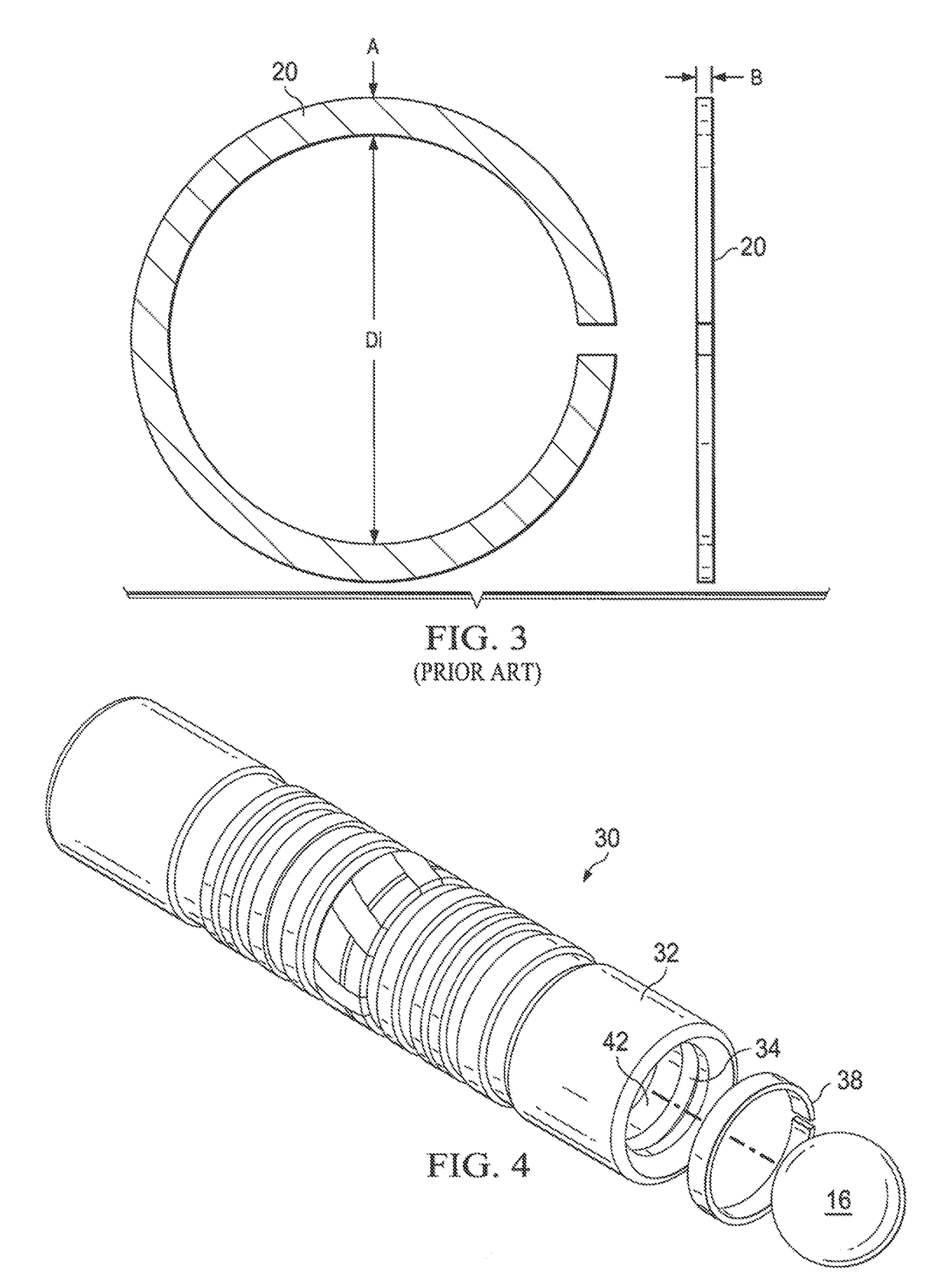

[0026]In an advance in the state of the art, an improved latching mechanism is described herein that extends the useful life of a two-piece ball and sleeve bypass plunger. The latching mechanism includes a single split retaining ring installed in a groove formed in the inside diameter of the sleeve portion of the bypass plunger. When the ball component is not in the plunger, the quiescent inside diameter of the retaining ring is slightly less than the diameter of the ball component. The groove is positioned relative to the spherical valve seat so the when the ball component of the valve is seated against the valve seat, the largest diameter portion of the ball is disposed just past the retaining ring, which expands slightly to allow the ball to pass through the ring and seat against the spherical valve seat. This is because the inside diameter of the retaining ring must be slightly smaller than the diameter of the ball to act as an effective latch mechanism. The cross section profil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com