Full-automatic washing machine

a washing machine and full-automatic technology, applied in the field of washing machines, can solve the problems of poor aesthetic sense, increased parts, installation and removal, etc., and achieve the effects of convenient clothes retrieval, relatively reduced height of the washing machine, and relatively increased tub heigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

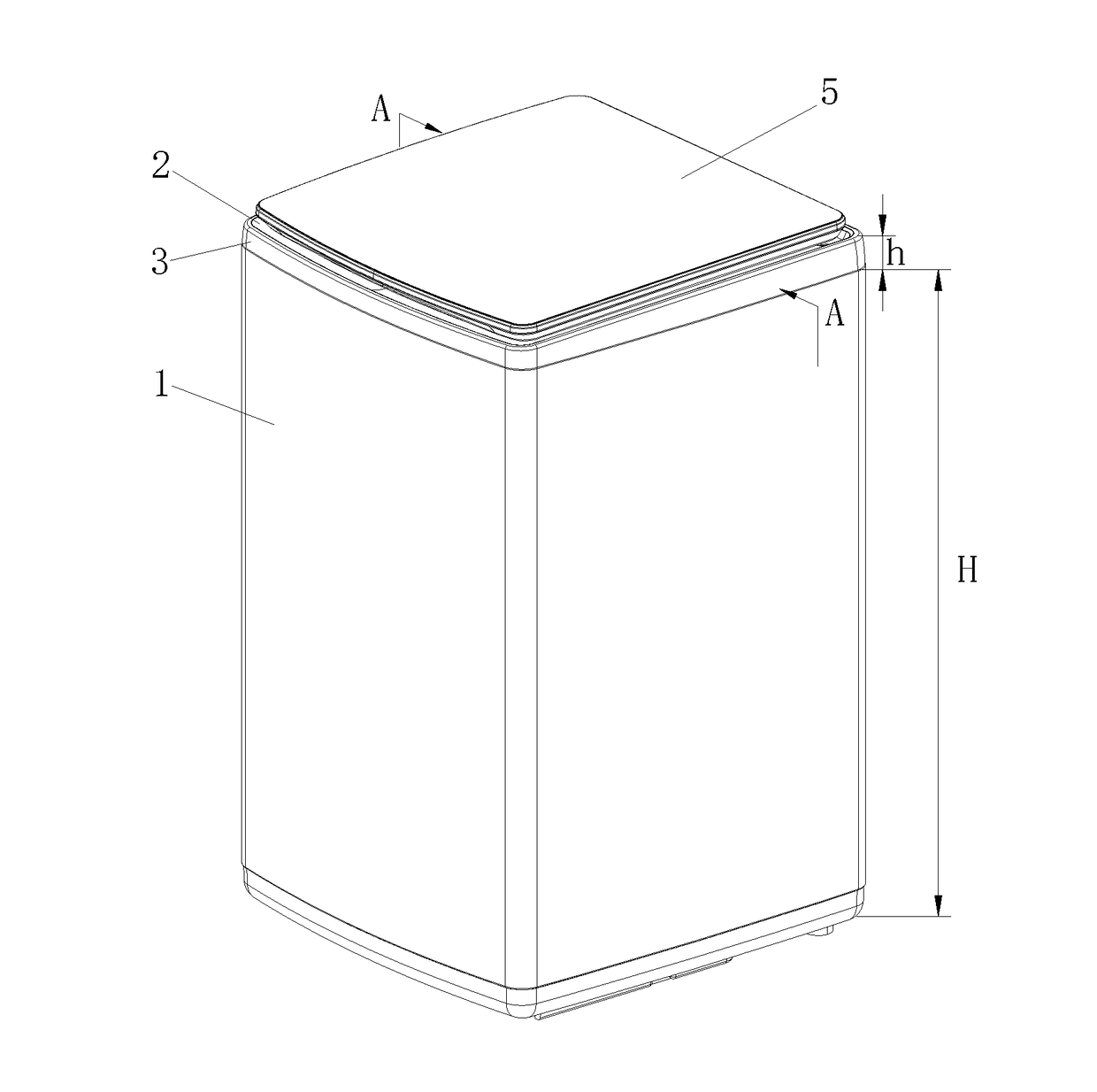

[0053]As shown in FIG. 1, a full-automatic washing machine disclosed by the embodiment comprises a box body 1 and a control panel seat 2, wherein the control panel seat 2 comprises a control panel seat lower part 21 inserted into an opening at the upper end of the box body 1 and a control panel seat upper part 22 exposed above the upper end of the box body 1. The height ratio h:H of the control panel seat upper part 22 to the box body 1 is in a range of 0.02 to 0.07, and preferably, the height ratio h:H of the control panel seat upper part to the box body is in a range of 0.03 to 0.06.

embodiment 2

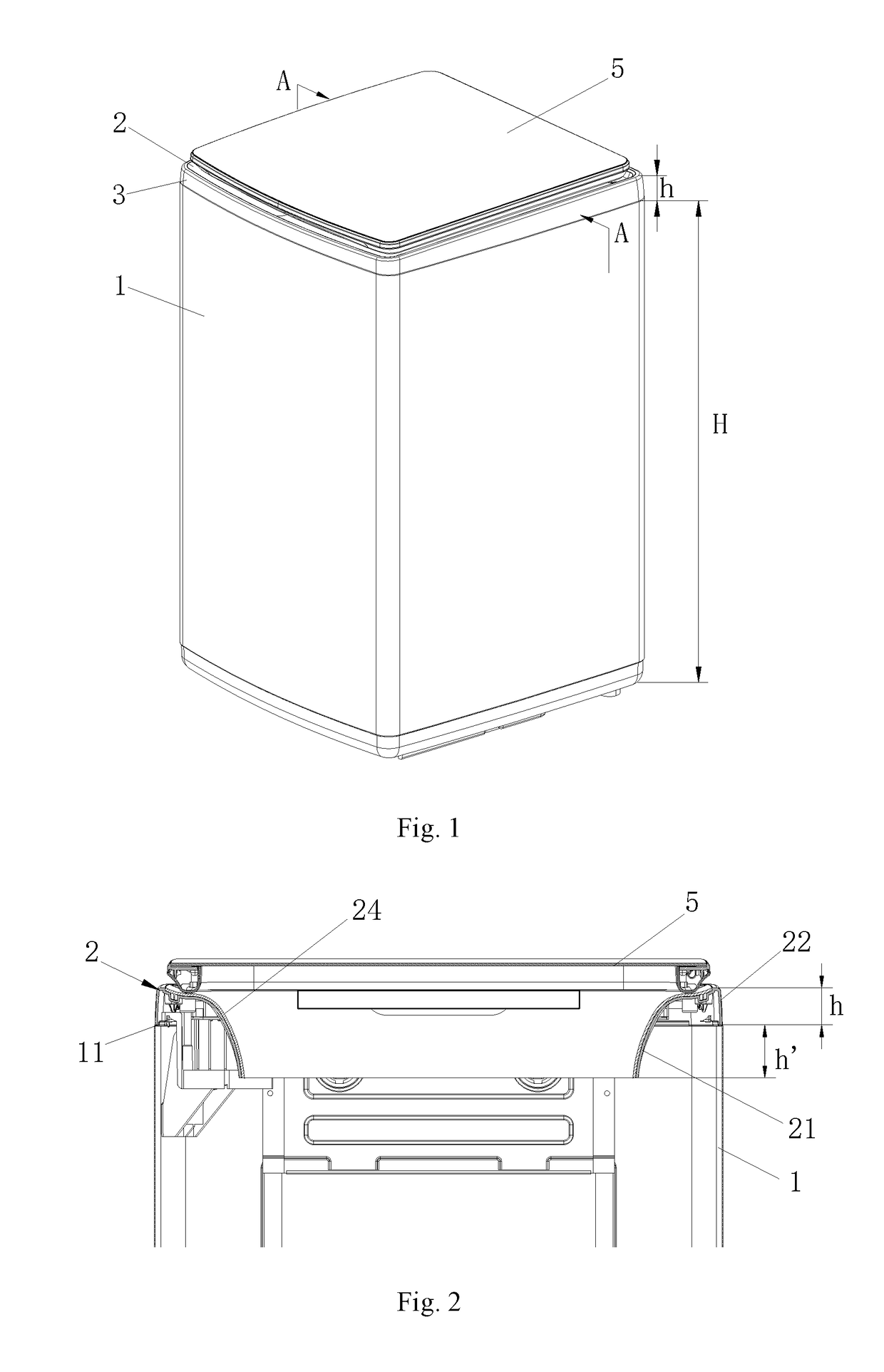

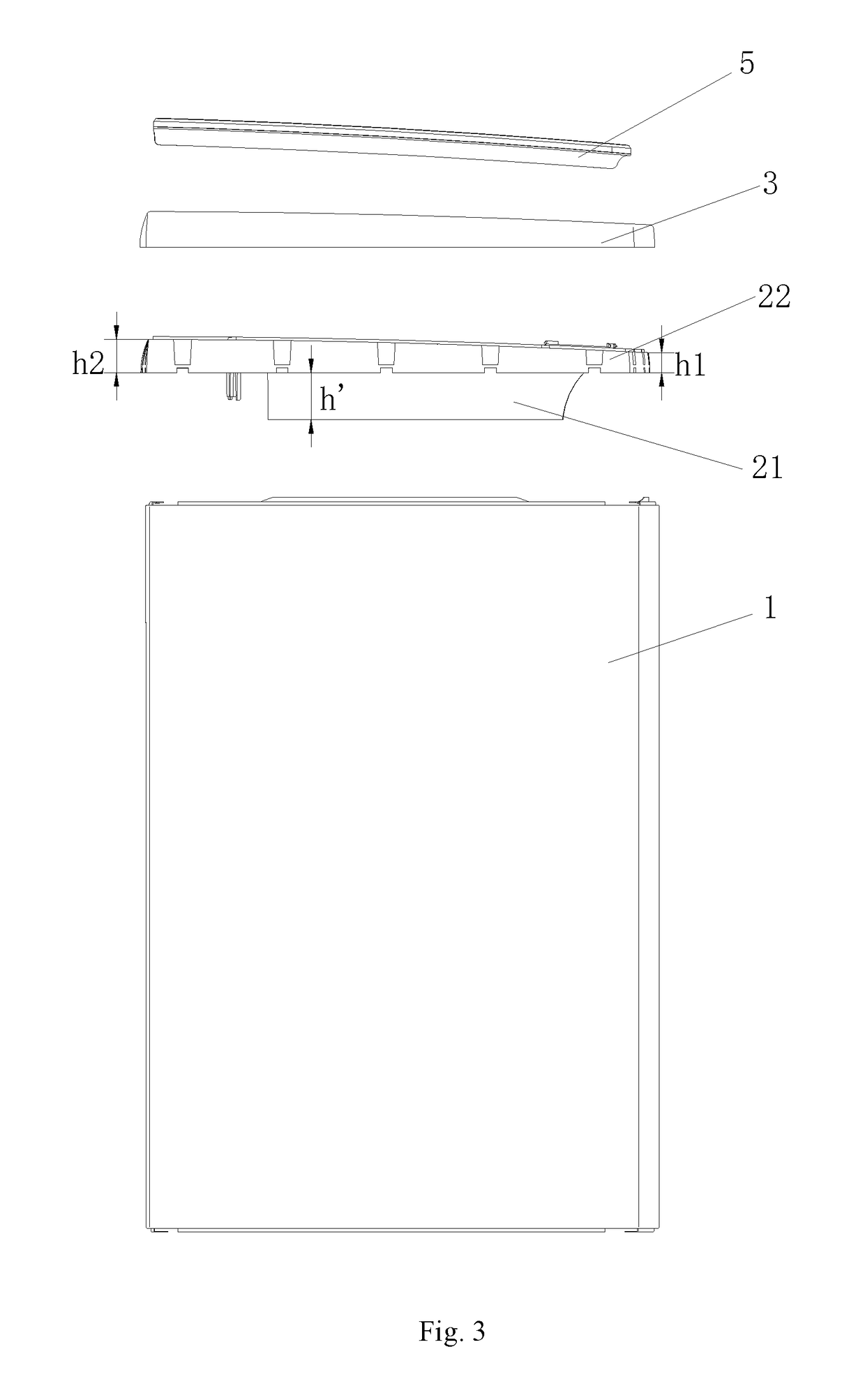

[0054]As shown in FIG. 2, another full-automatic washing machine disclosed by the embodiment comprises a box body 1 and a control panel seat 2, wherein the control panel seat 2 comprises a control panel seat lower part 21 inserted into an opening at the upper end of the box body 1 and a control panel seat upper part 22 exposed above the upper end of the box body 1, and the height ratio h:h′ of the control panel seat upper part 22 to the control panel seat lower part 21 is in a range of 0.2 to 1, and preferably, the height ratio h:h′ of the control panel seat upper part 22 to the control panel seat lower part 21 is in a range of 0.4 to 0.8.

embodiment 3

[0055]As shown in FIG. 5, the control panel seat 2 disclosed by the disclosure is a homocentric-square-shaped structure and comprises an outer peripheral wall 23 and an inner peripheral wall 24. The outer peripheral wall 23 is matched and connected with the upper end of the box body to form the control panel seat upper part 22; the lower end of the inner peripheral wall 24 extends into the box body 1 to form a clothes input opening 25, and the part of the lower end of the inner peripheral wall 24 that extends into the box body 1 is the control panel seat lower part 21. The height ratio h:(h+h′) of the outer peripheral wall 23 to the inner peripheral wall 24 is in a range of 0.25 to 0.5; and preferably, the height ratio h:(h+h′) is in a range of 0.3 to 0.45.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com