Coal dust treatment methods and compositions

a technology of coal dust and treatment methods, applied in the direction of solid fuels, petroleum industry, fuels, etc., can solve the problems of coal dust generation, black lung disease and other illnesses, slow oxidation to form, etc., and achieve the effect of enhancing foam stability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

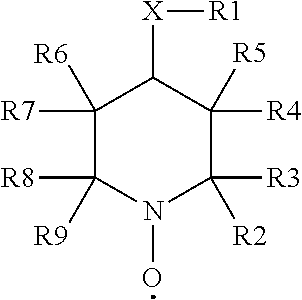

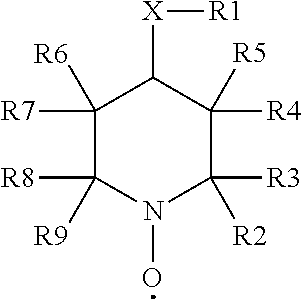

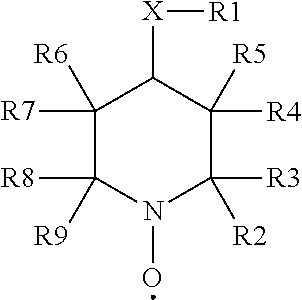

Image

Examples

example 1

[0030]In order to assess the efficacy of the materials in inhibition of coal dust self-ignition, coal self-heating tests were performed. This is an accelerated test method wherein a coal sample is heated to a predetermined temperature with a known quantity and flow of air being supplied. This method accelerates natural coal oxidation and leads to the coal reaching a thermal runaway state.

Coal Sample:

[0031]Coal crushed to −250 microns

Solutions and Application:

[0032]Chemistries are prepared at two different concentrations in water, 0.5% and 2%. The chemistries are applied to the coal at a rate so that the same amount of moisture (4%) is added to all coal samples.

Measurements:

[0033]Temperature of the coal sample is measured and logged. Time for the coal sample to reach thermal runaway (typically at 200 F) is recorded. The delay in time to thermal runaway for a treated coal sample versus blank and moisture only samples are used to evaluate anti-oxidation efficacy.

Procedure:

[0034]A coal ...

example 2

rol Improvement

Apparatus:

[0036]Dust Monitor—Lab scale dust monitor uses white light to determine dust levels of materials dropped into the sampling chamber.

Substrate:

[0037]Coal samples, mixture of size fractions to generate sufficient dust to study.

Procedure:

[0038]Prepare solutions of various concentrations of each of the products. Prepare untreated coal substrate samples with spinning riffler to ensure uniform particle size distribution for each sample. Apply products to the coal. Dry the samples at 140 F for 30 minutes. Cool at room temperature for 30 minutes. Pass samples through the Dust Monitor and record dust values. The reported value is Dust Area+Max, which is the area integrated under the curve for the sample measured over 30 seconds added to the maximum dust level recorded for the sample. Lower Dust Area+Max values are indicative of superior dust control.

[0039]In these examples, EX-1, namely 4HT was added to coal without any dust control agent, and in addition to a known d...

example 3

ility

[0042]4HT was added to a known foaming agent, “C4”, an anionic surfactant, sodium olefin (C14-C16) sulfonate to determine its effect on foam stability.

Solutions:

[0043]200 mL solutions at ambient temperature (72° F.)

Apparatus:

[0044]Waring Commercial Blender (Model 7011G) marked with 50 mL graduations

Measurements:

[0045]Maximum foam height (to nearest 25 mL)[0046]½ life time (in sec)—time for 100 mL of solution to drain back into liquid phase

Procedure:

[0047]200 mL of solution was poured into the blender. The blender was turned on low speed for 30 seconds. The blender was then allowed to sit until half of the sample (100 mL) returned back to liquid state. The amount of time that passed until the liquid-foam interface hit the 100 mL mark was recorded as “foam ½ life time.”

Results are shown in Tables 3 and 4

TABLE 3Foam ½ life (min:sec)C4 + 4HT 0.75% +C4 + C2C4 %C4 onlyC4 + 4HT 1.5%C2 0.75%0.75%0.11:513:573:492:380.33:415:575:393:220.54:316:106:294:100.75:016:526:474:370.95:087:107:07...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap