Spray can

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

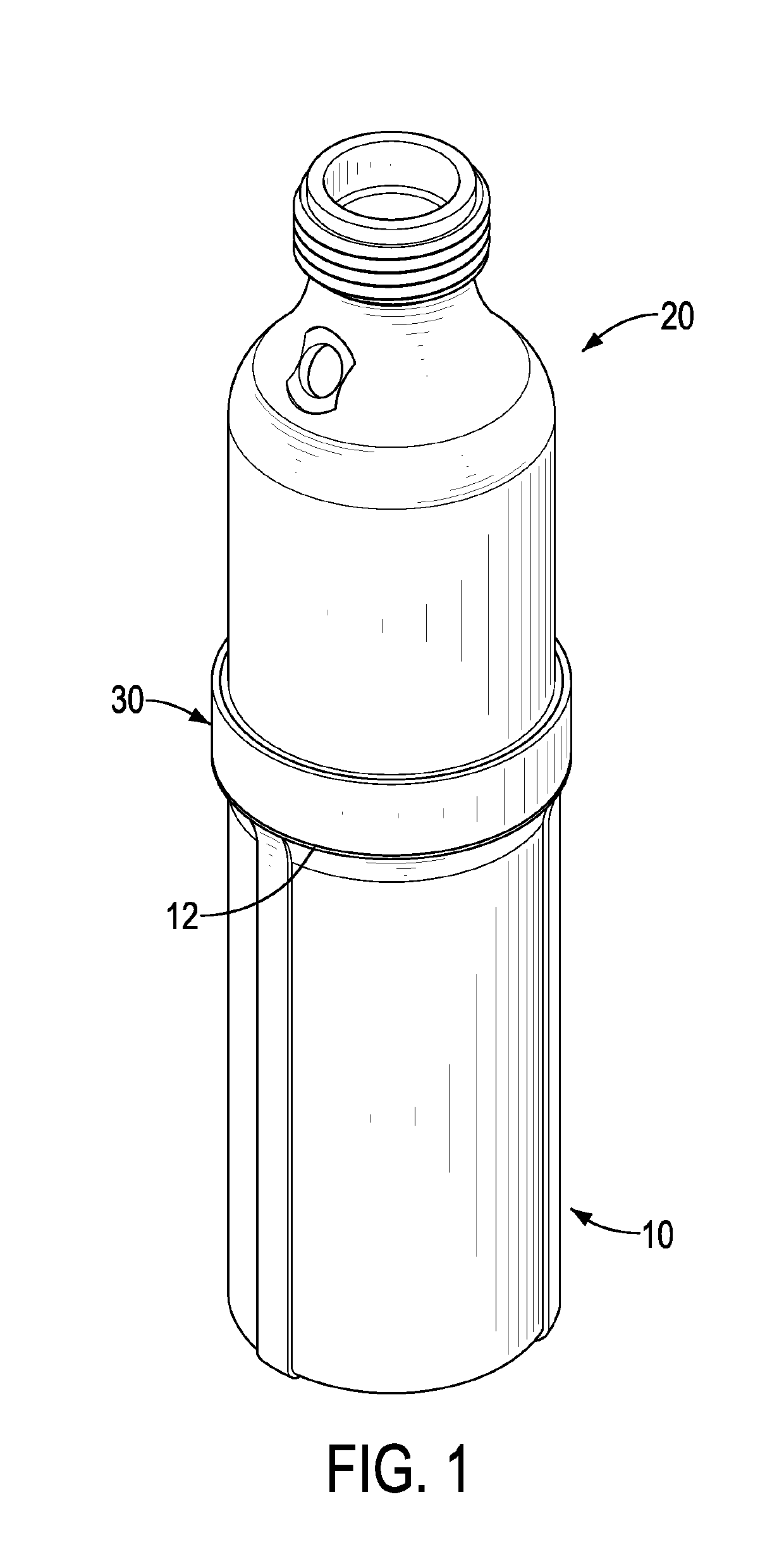

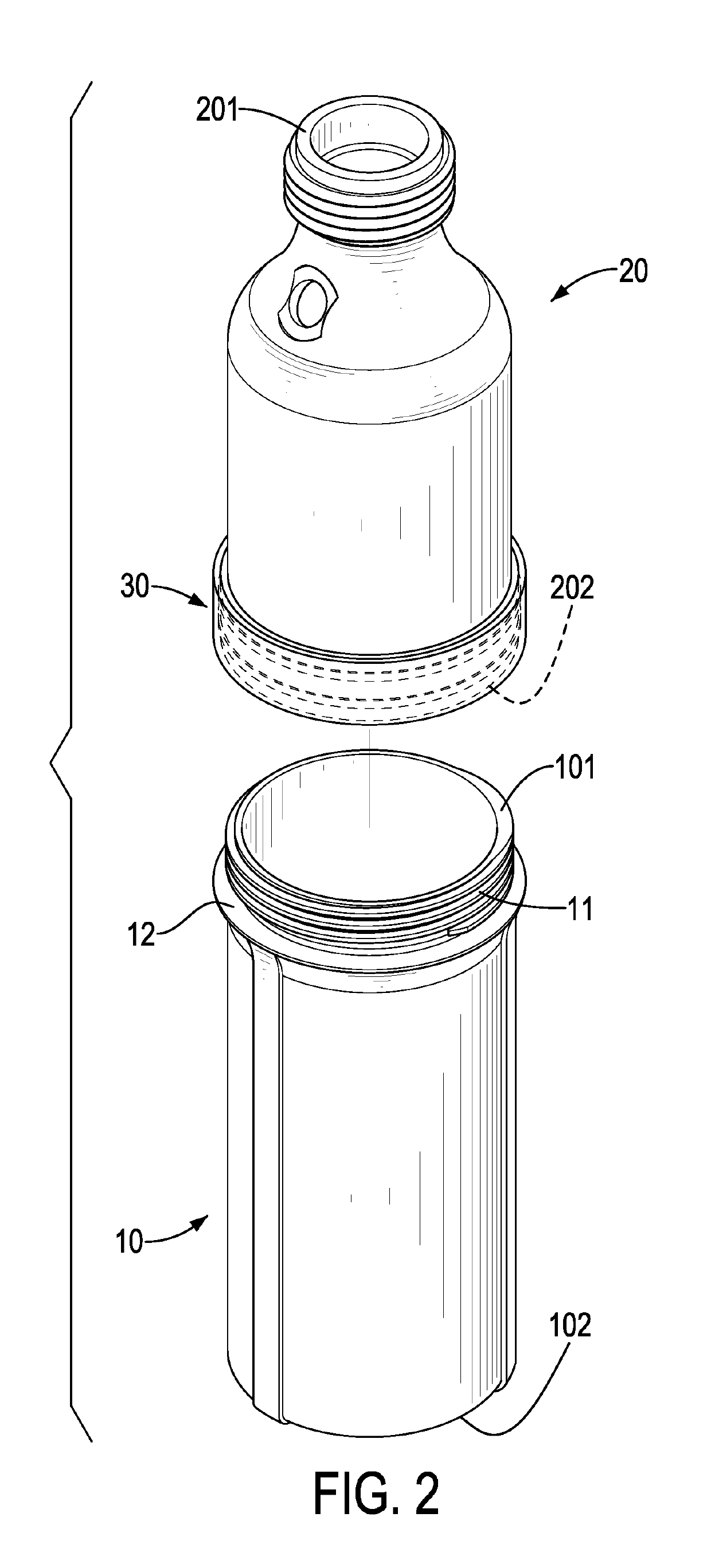

[0017]With reference to FIGS. 1 and 2, a spray can in accordance with the present invention has a first body 10, a second body 20, and a reinforcing sleeve 30. The second body 20 is mounted to the first body 10. The reinforcing sleeve 30 is sleeved on the second body 20. The second body 20 and. the reinforcing sleeve 30 are fixed together.

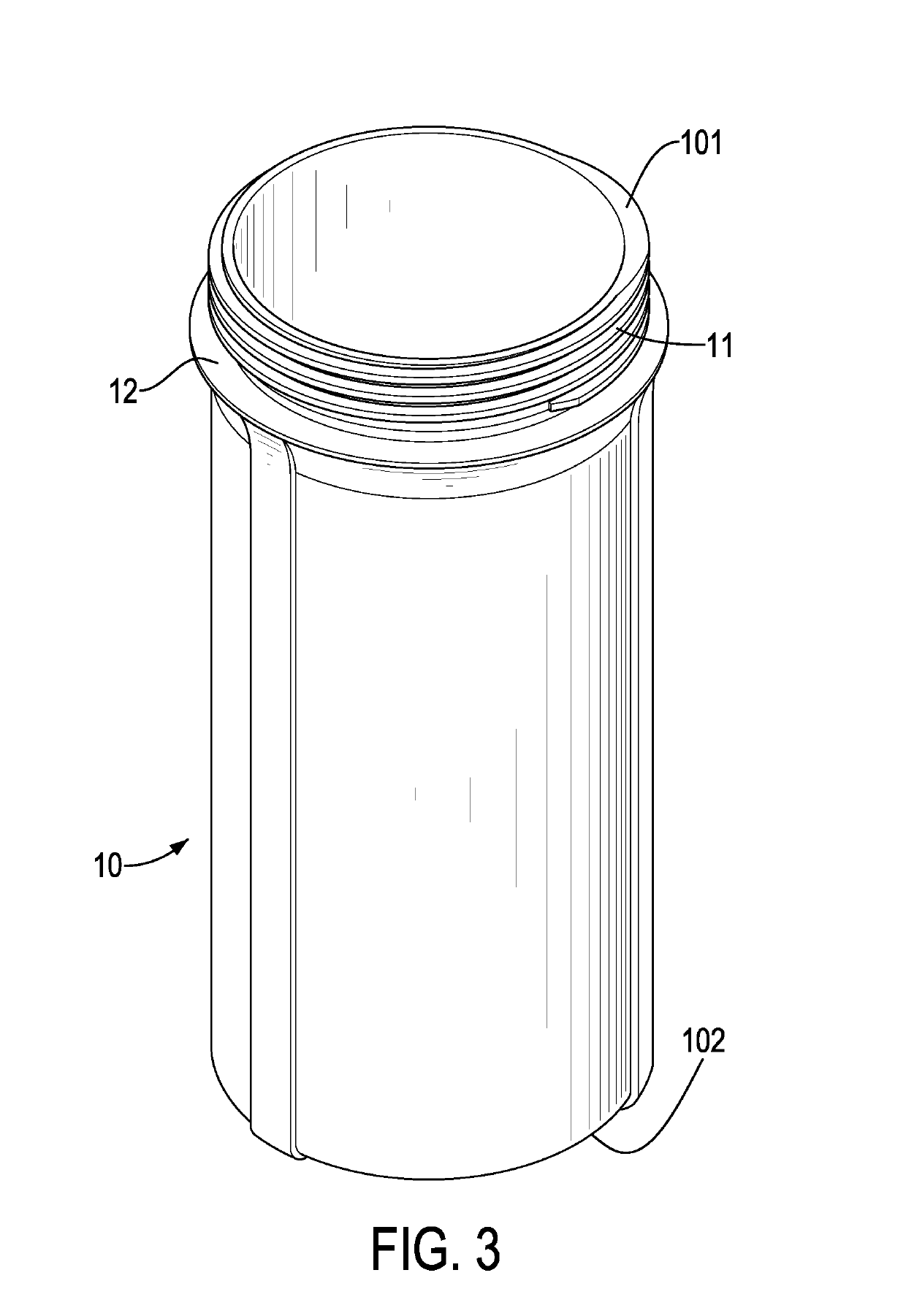

[0018]With reference to FIGS. 2, 3, and 4, the first body 10 is made of plastic. The first body 10 has a lengthwise direction, an inner circumference, an outer circumference, a first end 101, a second end 102, an assembling portion 11, an annular abutting portion 12, and a gas injection hole 13. The inner circumference and the outer circumference of the first body 10 are opposite each other. The first end 101 and the second end 102 of the first body 10 are opposite in the lengthwise direction of the first body 10. The assembling portion 11 is disposed at the first end 101 of the first body 10. The assembling portion 11 has a thread formed on the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com