Electrically Operated Pressure Regulating Valves for Adjustable Hydrostatic Pumps

A technology of pressure regulation and hydrostatic pumps, which is applied to components of pumping devices for elastic fluids, electric fluid pressure control, fluid pressure actuation devices, etc., can solve the problems of high expenditure and structural space requirements, and achieve Effect of reduced expenditure and structural space requirements, reduced consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

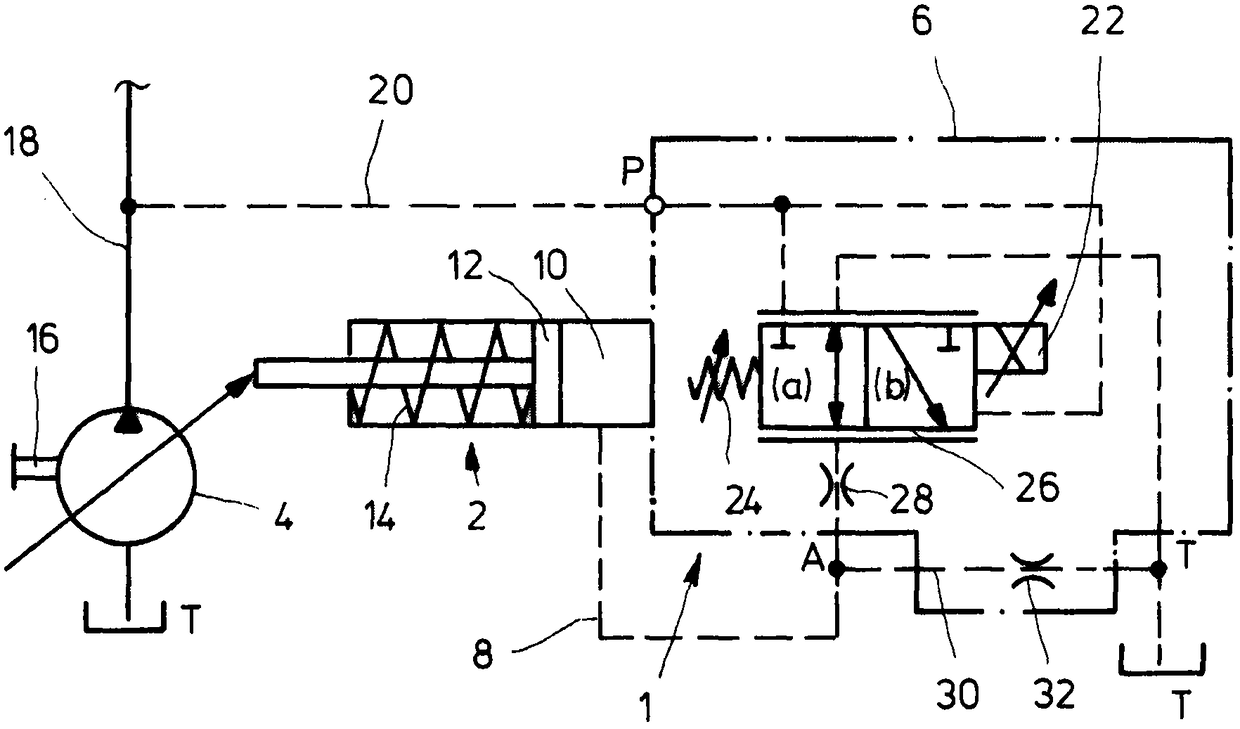

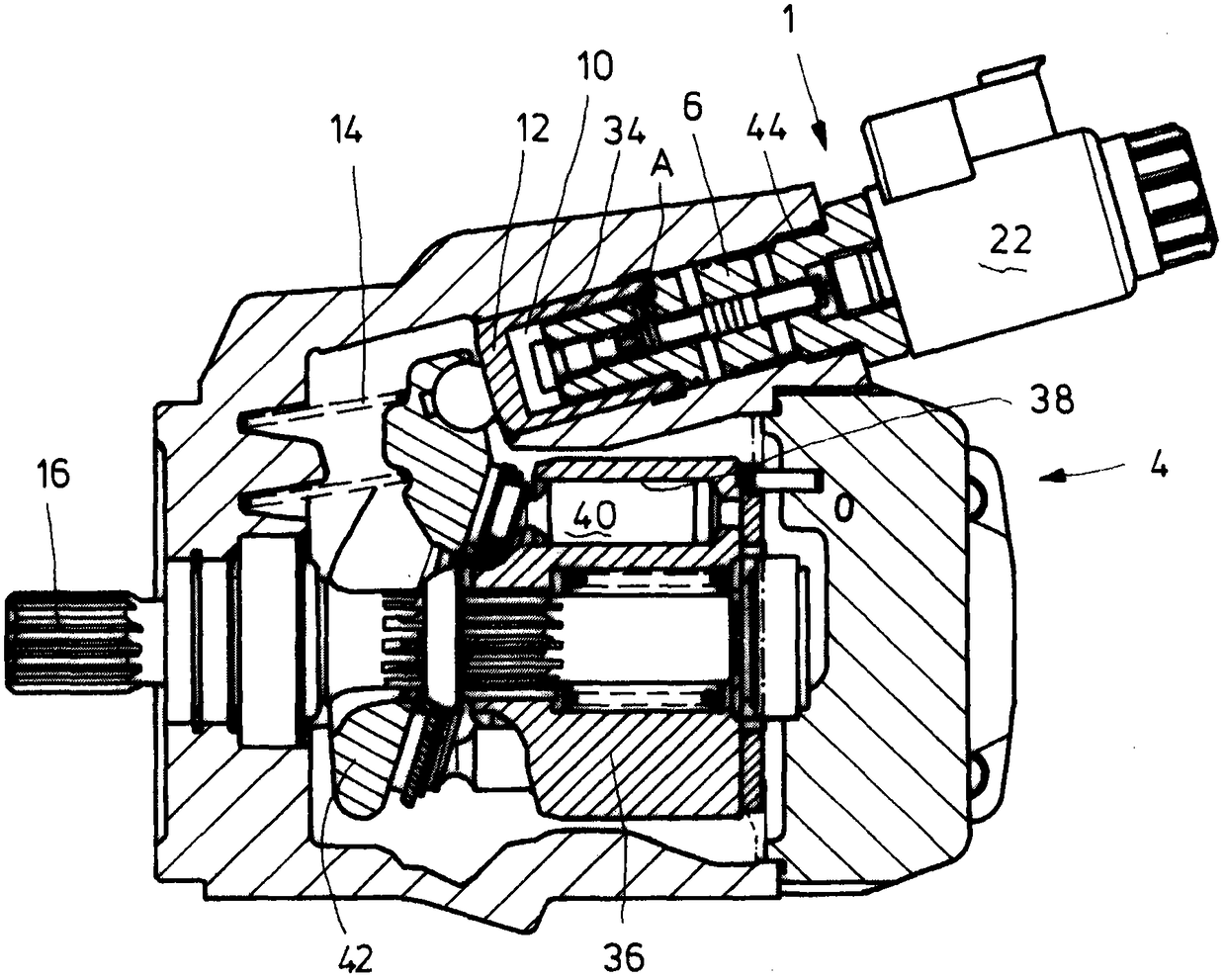

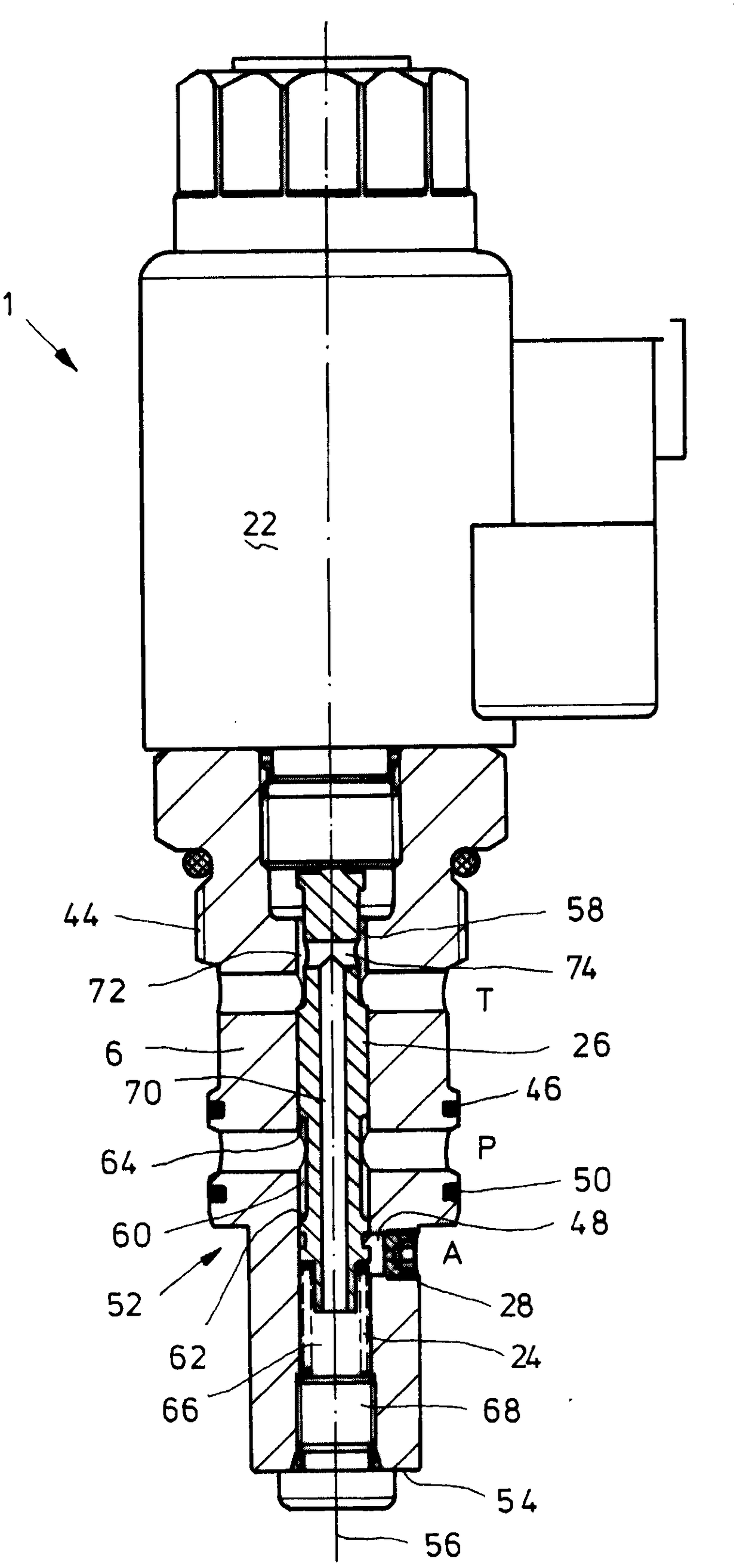

[0030] figure 1 A circuit diagram is shown of an exemplary embodiment of a directly controlled pressure regulating valve 1 according to the invention for supplying the regulating cylinder 2 of an axial piston pump 4 with adjustable static pressure. For this purpose, an actuating pressure connection A arranged on the valve housing 6 is connected via a control pressure line 8 to an actuating pressure chamber 10 of the actuating cylinder 2 . Filling the adjusting pressure chamber 10 with adjusting pressure medium causes the adjusting piston 12 to move against the force of the adjusting spring 14 , thereby reducing the delivery quantity of the axial piston pump 4 and thus indirectly reducing the operating pressure of the dispersive axial piston pump.

[0031] The axial piston pump 4 is driven via a drive shaft 16 and delivers pressure medium from a tank T into a working line 18 . Via the control and regulation pressure channel 20 , the working line 18 is connected to the pump con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com