Self-positioning screw joint

a screw joint and self-positioning technology, which is applied in the direction of threaded fasteners, bolts, transportation and packaging, etc., can solve the problems of large space available for the installation of components, and the lack of necessary space for mounting components on the vehicle, so as to simplify the installation/removal properties and facilitate the installation. , the effect of simple and cost-effective mounting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

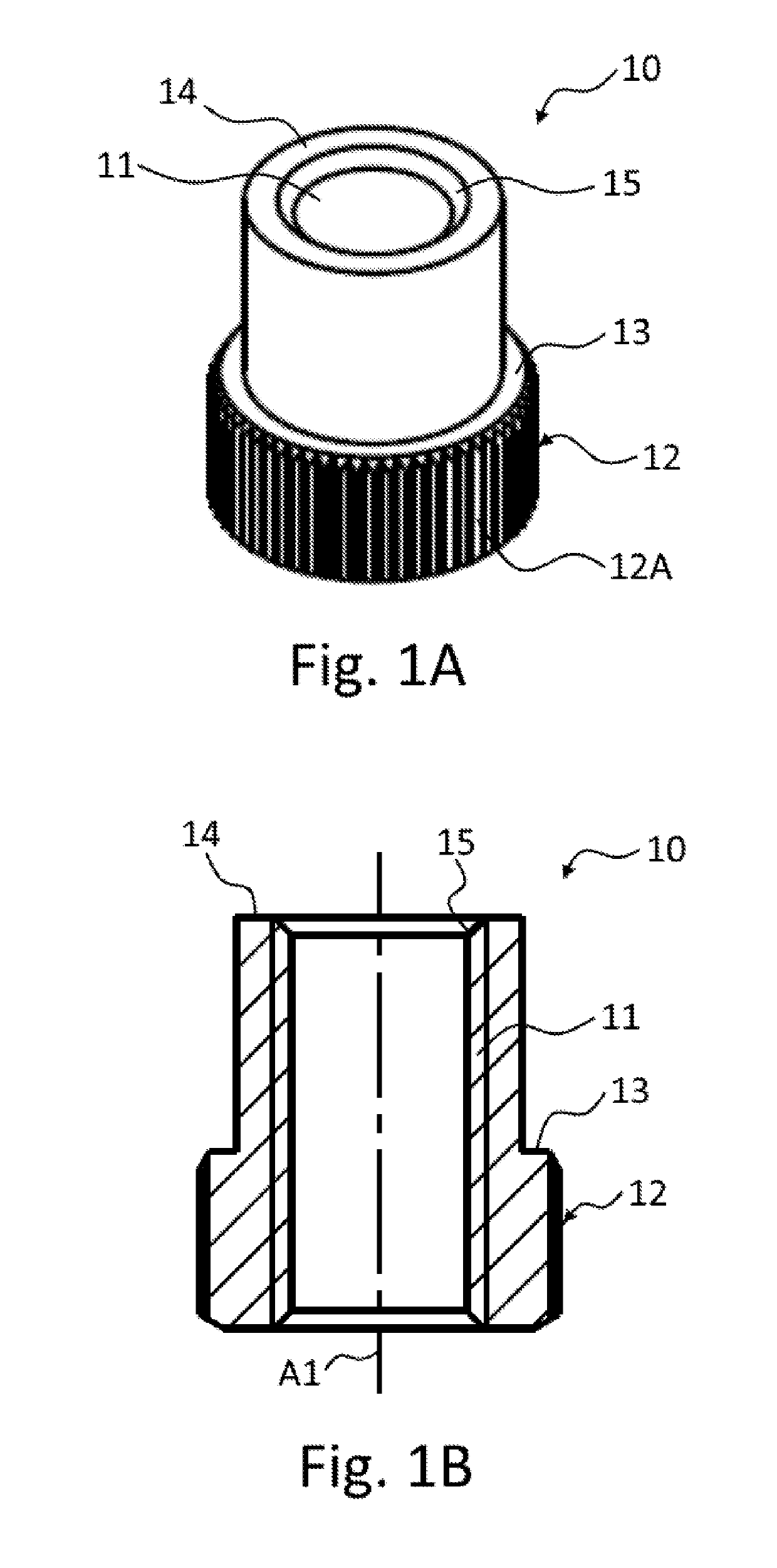

[0041]FIG. 1A shows a perspective view of a bearing bush 10 according to one embodiment. The bearing bush 10 is of substantially cylinder-shape design and includes a bore which runs through the bearing bush 10 and is provided with an internal thread 11. The bore of the bearing bush 10 can alternatively be provided without or at least only partially with an internal thread 11. At least the inner surface of the bore can be formed here from a softer material than the complementary bearing screw 40 (see FIG. 3 et seq.), and therefore, as the bearing screw 40 is screwed into the bore of the bearing bush 10, said bearing screw bites or cuts into the inner surface of the bore of the bearing bush 10.

[0042]The bearing bush 10 furthermore has an encircling fixing portion 12 which protrudes in relation to the rest of the bearing bush 10 radially with respect to an axis A1 of the bearing bush 10. The fixing portion 12 is formed here with a multiplicity of wedges or wedge-shaped projections 12A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com