Modified peanut butter composition and method of producing same

a technology of modified peanut butter and composition, which is applied in the field of modified peanut butter composition, can solve the problems of significant diluted or deleted peanut butter flavor, unsuitable use, and dripping of peanut butter, and achieve the effect of improving the shelf life of modified peanut butter and high moldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013]Selected embodiments will now be explained with reference to the drawings. It will be apparent to those skilled in the art from this disclosure that the following descriptions of the embodiments are provided for illustration only and not for the purpose of limiting the invention as defined by the appended claims and their equivalents.

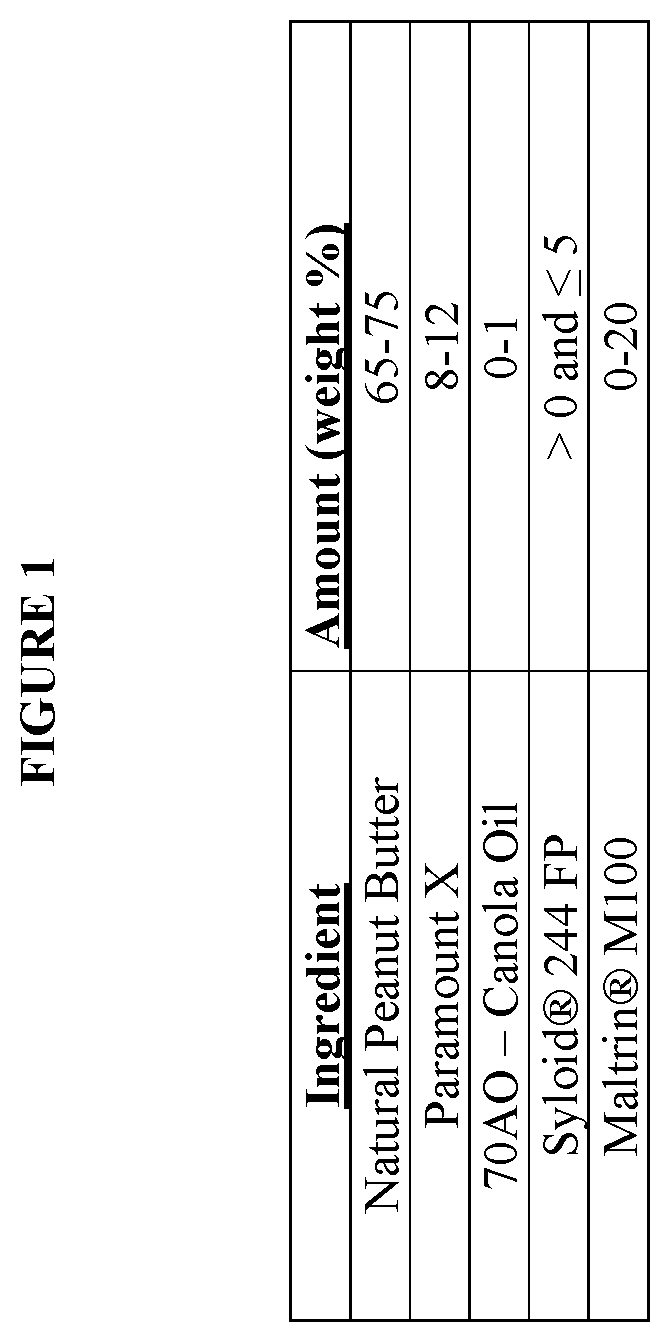

[0014]Referring initially to FIG. 1, a modified peanut butter composition is illustrated in accordance with an embodiment. The modified peanut butter composition includes approximately 65% by weight to 75% by weight of natural peanut butter, approximately 8% by weight to 12% by weight of hard butter, up to 1% by weight of canola oil, greater than 0% by weight and less than or equal to 5% by weight of fumed silica or silica gel, and up to 20% by weight of a filler. The modified peanut butter composition preferably includes 69.18% by weight of natural peanut butter, 10.20% by weight of Paramount X, 0.50% by weight of 70AO—Canola Oil, 2.00% by weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com