Hidden edge for flooring finishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

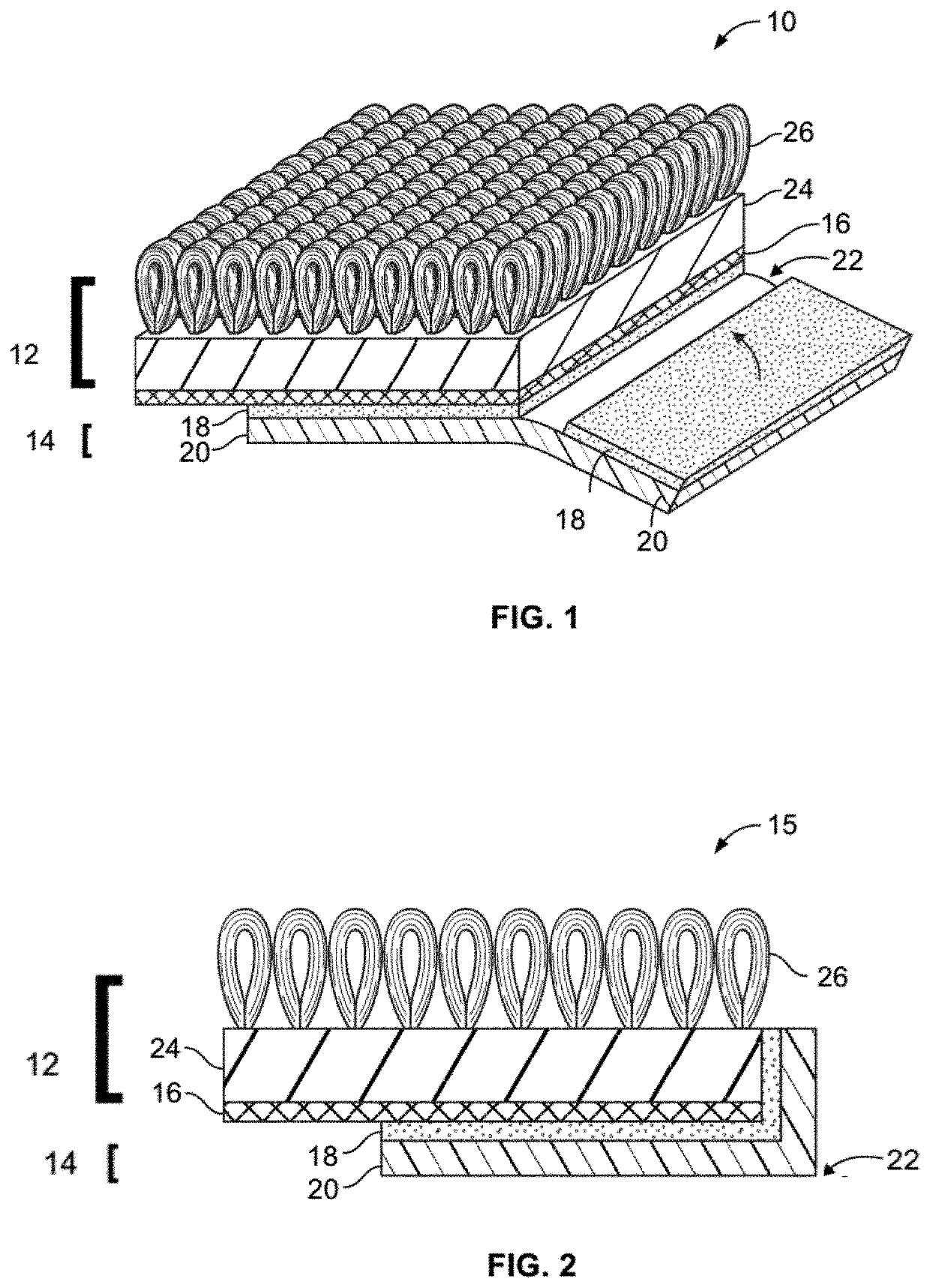

[0017]FIG. 1 shows a particular embodiment of an unbound assembly 10 of a carpet 12 and a flooring edge finish 14. The carpet 12 has face fibers 26 embedded into a carpet backing 24 and a carpet pad 16, which is optional, underneath the carpet backing 24. The flooring edge finish 14 includes a flexible strip 20 having an adhesive 18 on a top surface of the flexible strip 20 and a hinge 22 comprising a gap or an absence of the adhesive or a lower amount of the adhesive 18 on a portion of the top surface of the flexible strip 20. The flooring edge finish 14 is upwardly foldable along the hinge 22 to bind, protect, and conceal an edge of a flooring.

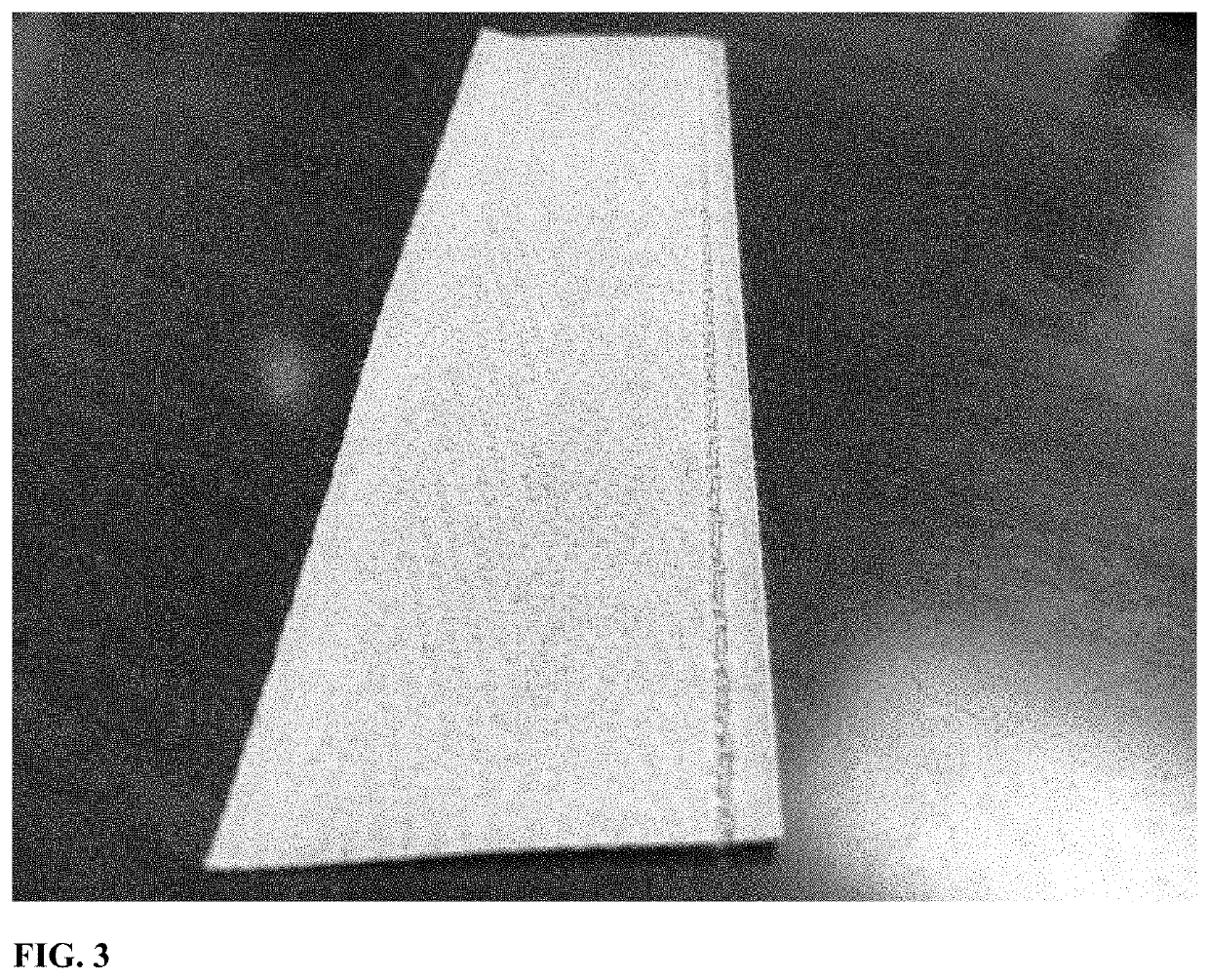

[0018]FIG. 2 shows a particular embodiment of a bound assembly 15 of a flooring edge finish 14 adhered to a carpet 12. As in FIG. 1, the carpet 12 has fibers 26 embedded into a carpet backing 24 and an optional carpet pad 16 underneath the carpet backing 24. The flooring edge finish 14 has been folded upward approximately 90 degrees along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com