Reamer Wear Protection Assembly and Method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

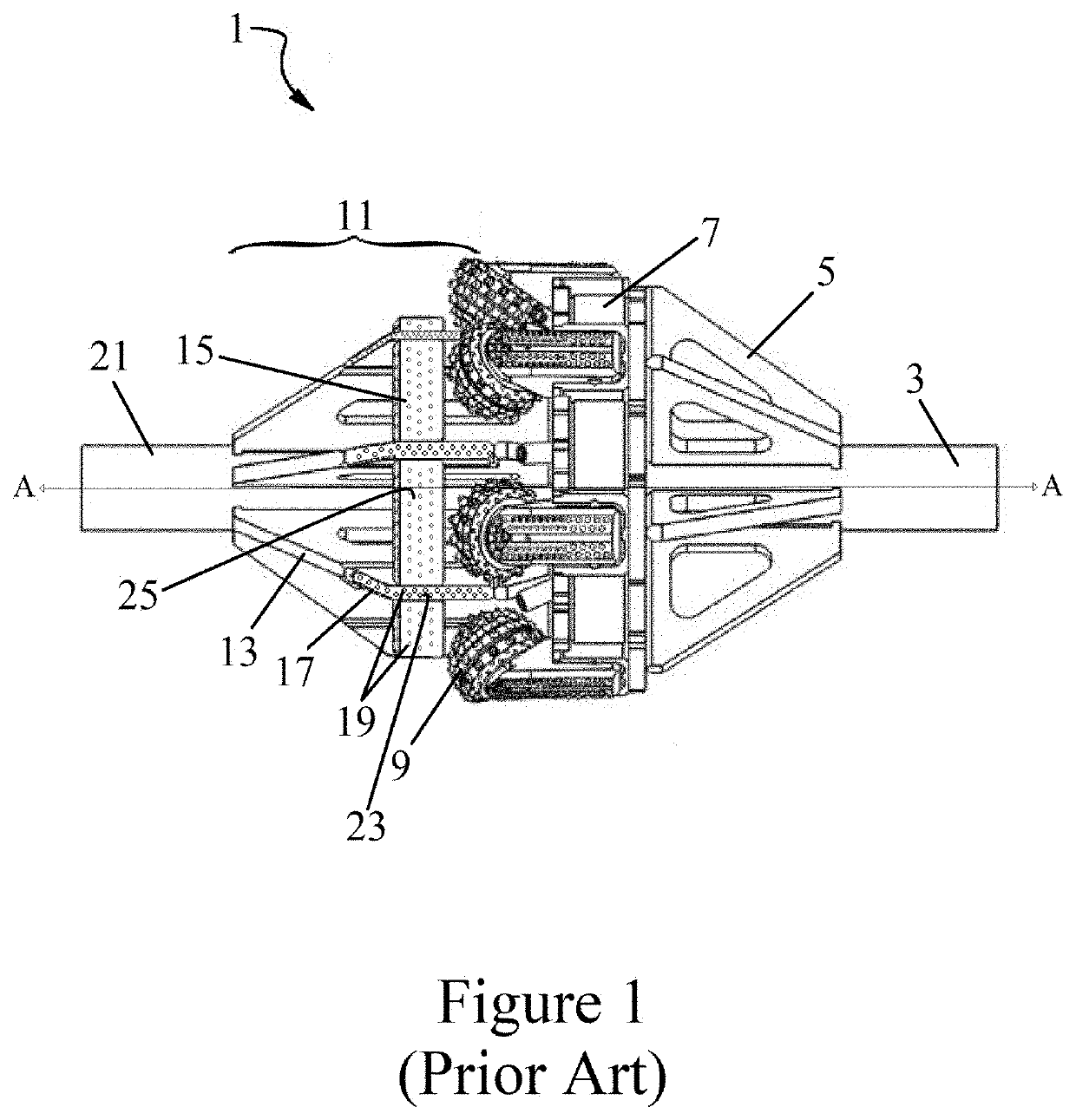

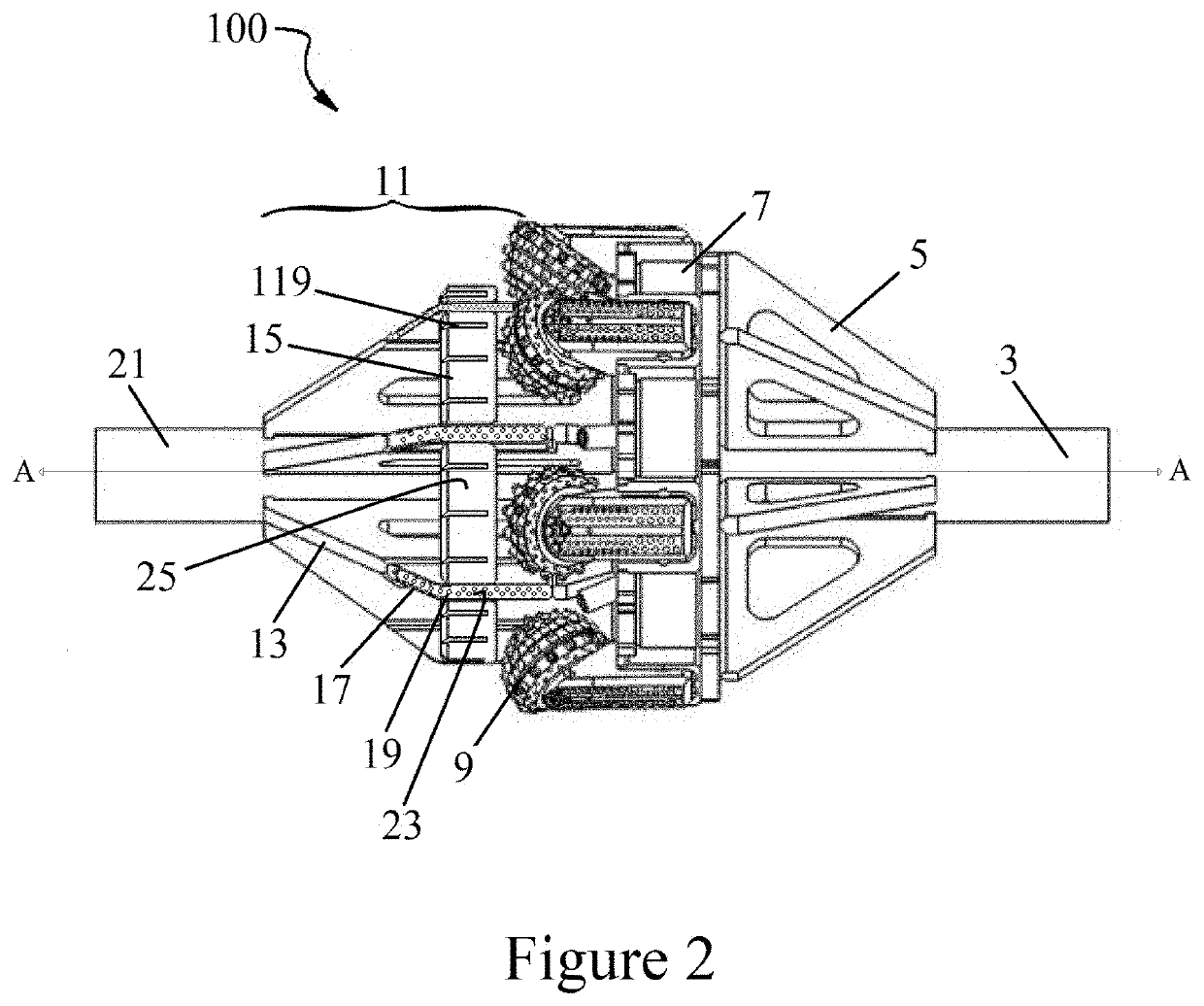

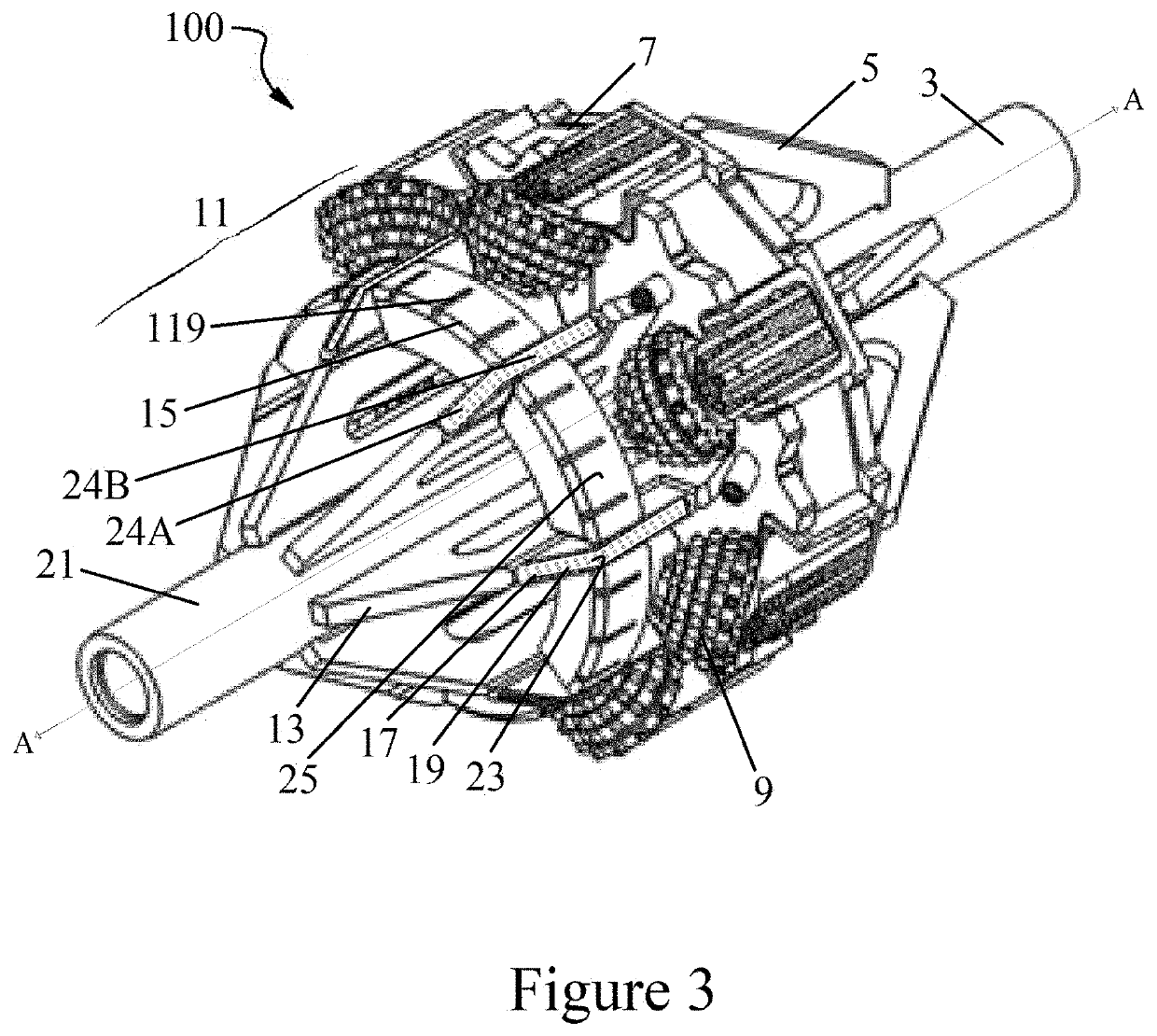

[0017]The exemplary embodiments are best understood by referring to the drawings with like numerals being used for like and corresponding parts of the various drawings. As used herein, longitudinal refers to the axis A-A identified in FIGS. 1 and 2 (i.e., the axis of rotation of the reamer), and axial refers to a direction perpendicular to axis A-A of FIGS. 1 and 2. The directions top and bottom as used in this specification are used for descriptive purposes only, and other orientations are contemplated.

[0018]Referring to FIG. 1, a prior art reamer 1 is depicted. As shown in FIG. 1, reamer 1 comprises an up-hole pipe section 3, up-hole gussets 5, fluid chambers 7, cutting elements 9, front end 11, and a down-hole pipe section (collar) 21. In the reamer depicted in FIG. 1, front end 11 comprises front-end gussets 13, longitudinal corebuster components 17, and axial corebuster components (“pie wedges”) 15. Longitudinal corebuster components 17 and / or pie wedges 15 may comprise a plura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com