Connecting means for two members in fluid conducting assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

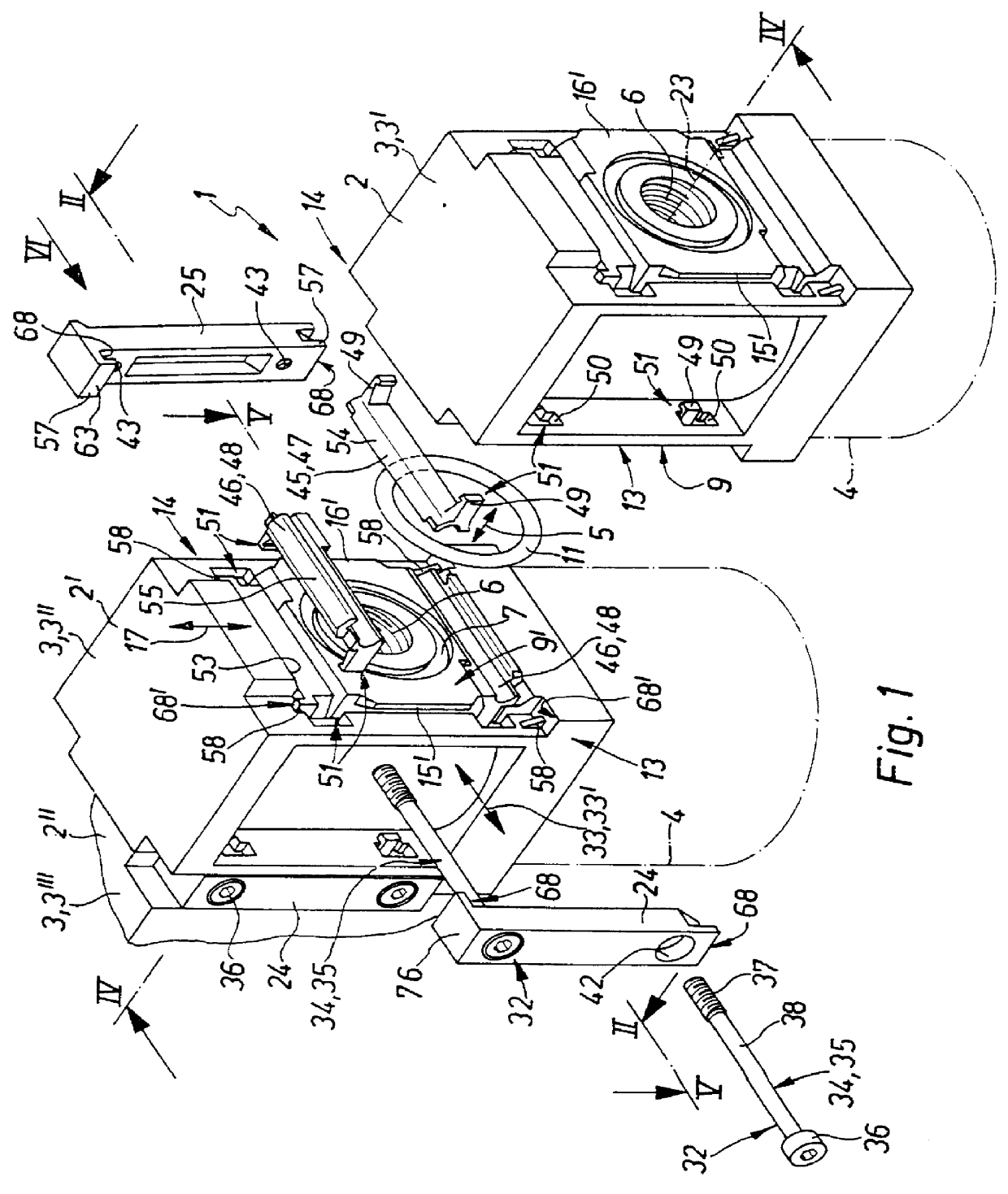

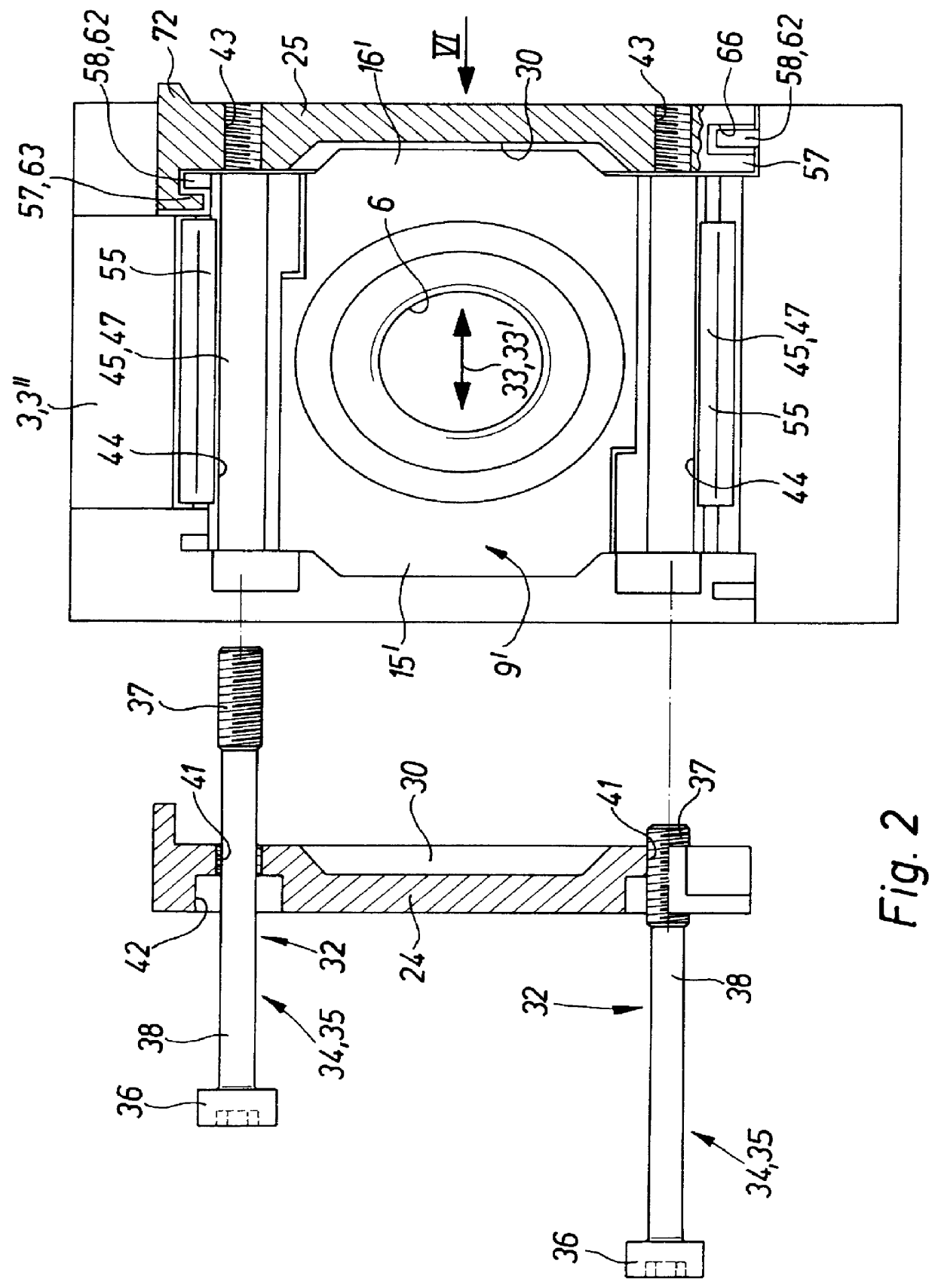

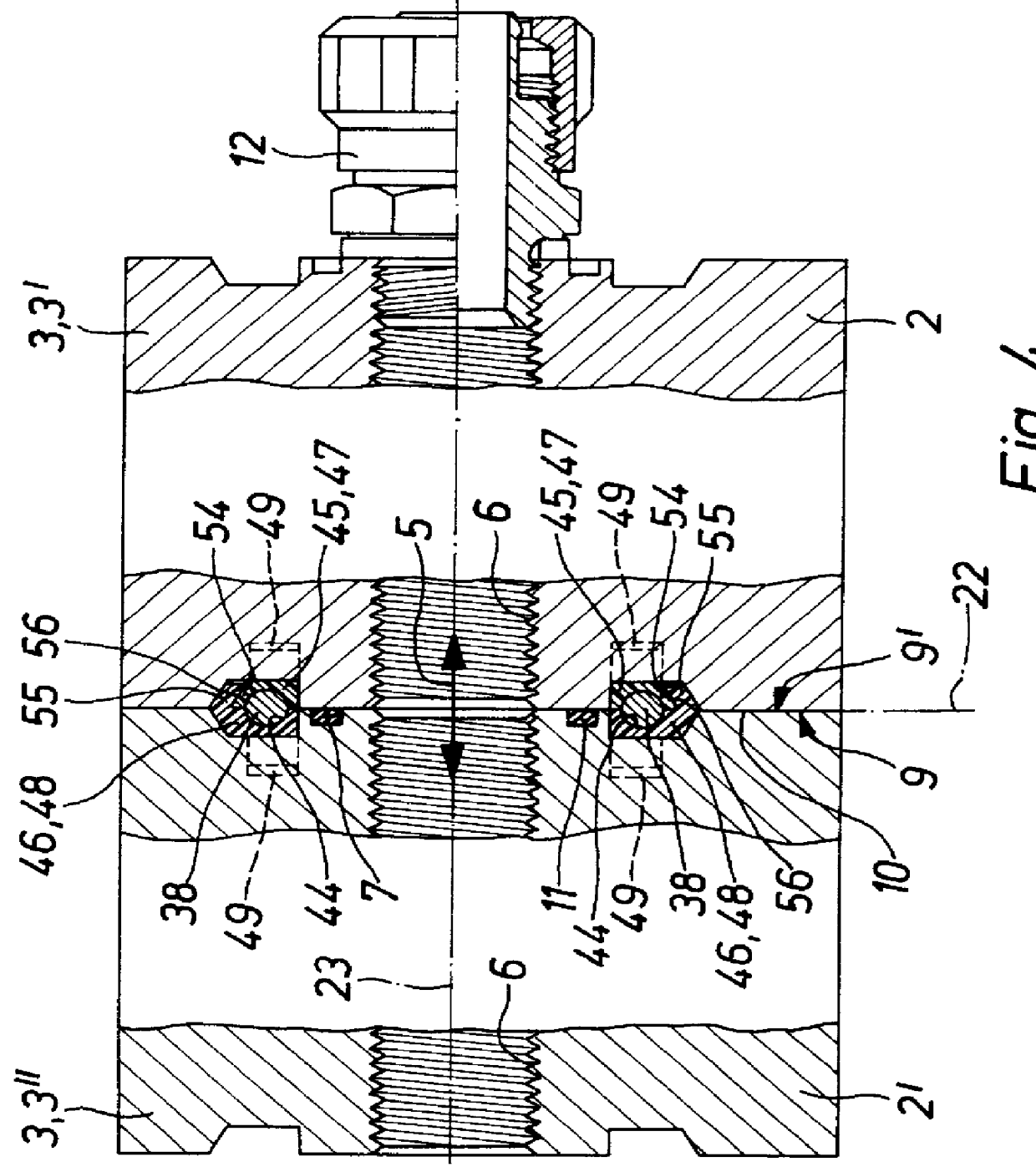

FIG. 1 diagrammatically shows a means 1 placed somewhere along a compressed air line, not illustrated in detail, for handling or treating the compressed air. The means could also be termed a servicing means or a conditioning means for compressed air. It is a question of a modularly designed component assembly through which in operation fluid flows, and which for instance comprises three working units 2, 2' and 2" only illustrated diagrammatically, in the case of which it is a question of a filter unit 2, a pressure setting unit 2' and an oiler unit 2".

The individual working units 2, 2'and 2" respectively possess a cubic or block-like main or housing part 3, which is in the following will be simply termed a "part". On the respective part 3, as for example on its bottom side, a functional unit 4 can be arranged, which for the sake of simplicity is only diagrammatically shown.

Each part 3 has an internal fluid duct 6, which opens at opposite terminal faces of the respective part 3. Any ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com