Tubular expansion apparatus and method

a technology of tubular expansion and swedge cone, which is applied in the direction of drilling casings, drilling pipes, borehole/well accessories, etc., can solve the problems of unsuitable open hole applications, unsuitable for open hole applications, and the use of fixed-diameter swedge cones is somewhat impractical, so as to avoid hanging up on removal and raise the gas pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

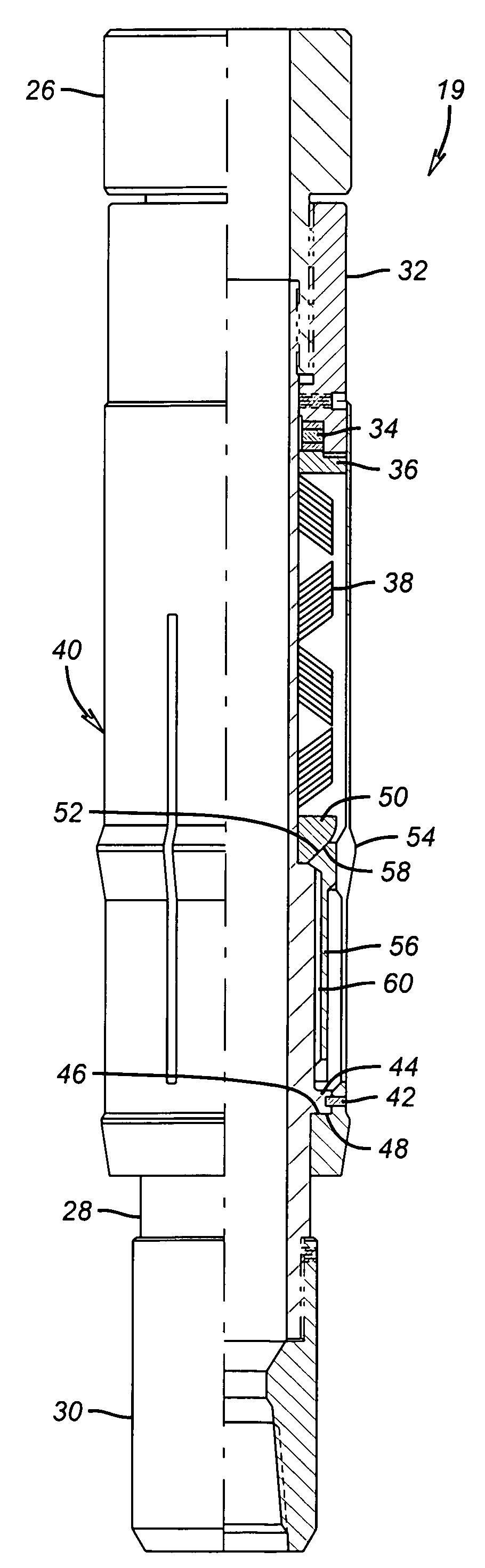

[0018]FIG. 1 generally shows the components of a one-trip system for expansion of tubulars downhole. An anchor 10 is set in casing 12. Below the anchor 10 is the liner running tool 14, which is in turn connected to the hydraulic drive assembly 16. The drive assembly 16 advances the swedge cone 18 to expand the blank pipe 20, with anchor 10 selectively engaged to the casing 12. Mounted below the blank pipe 20 can be screens 22 (shown prior to expansion), or a combination of screens with additional blank pipe between screen sections, in the open hole 24 section of the borehole. Generally, “tubulars” as used herein is intended to cover tubes, whether solid or having openings, liners, and screens.

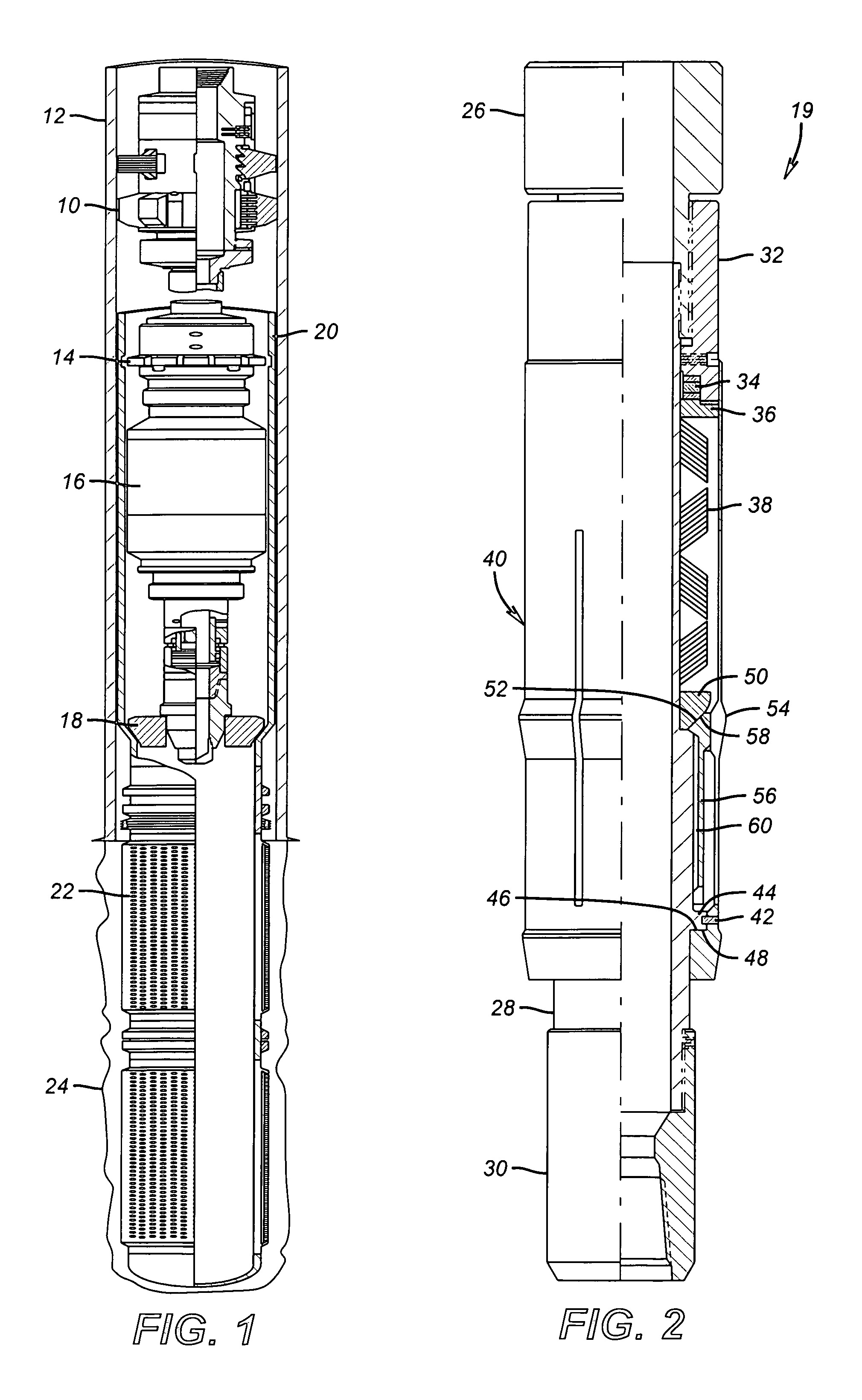

[0019]Referring to FIG. 2, an embodiment more particularly suited to expansion of blank pipe 20 in casing 12 is shown. Tool 19 has a top connection 26, which is attachable to the hydraulic drive assembly 16, such as shown schematically in FIG. 1. Top connection 26 is connected to body 28, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com