Underfilling process in a molded matrix array package using flow front modifying solder resist

a technology of molded matrix array and flow front, which is applied in the manufacture of printed circuits, basic electric elements, printed circuit assembling, etc., can solve the problems of reducing the reliability of the package, the molding process, and the possibility of air trapped under the di

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]In the following description numerous specific details are set forth. However, it is understood that the embodiments of the invention may be practiced without these specific details. In other instances, well-known details such as particular materials or methods have not been shown in detail in order not to obscure the understanding of this description.

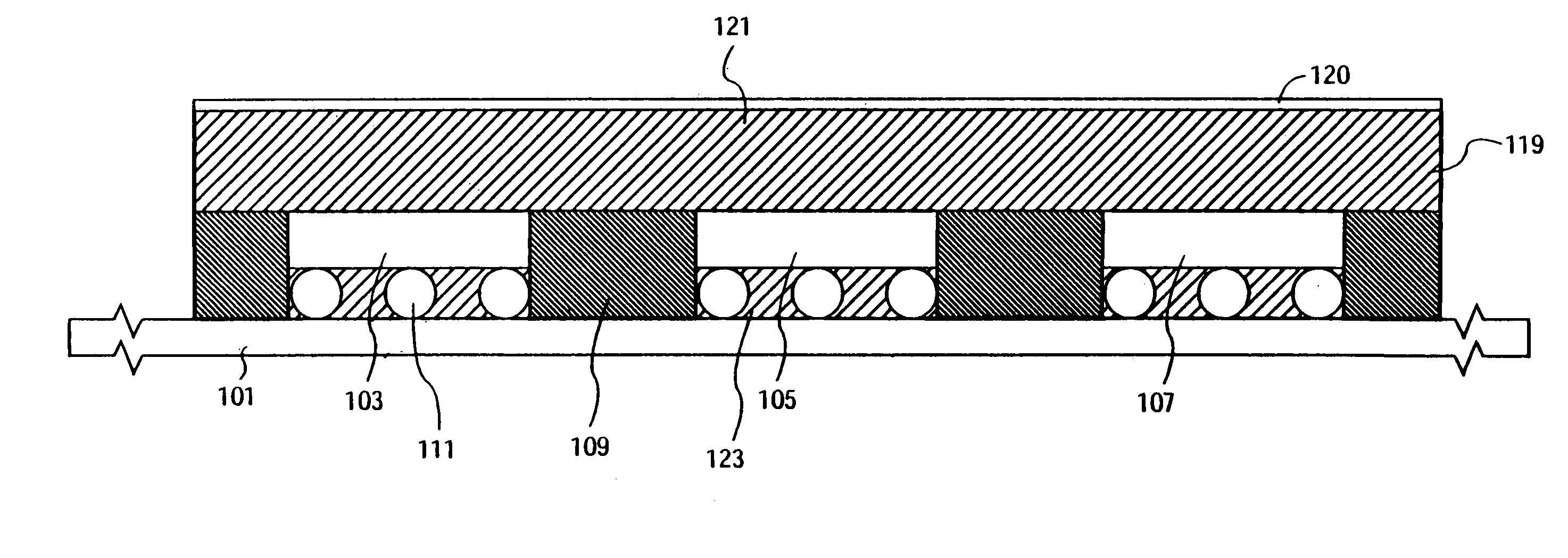

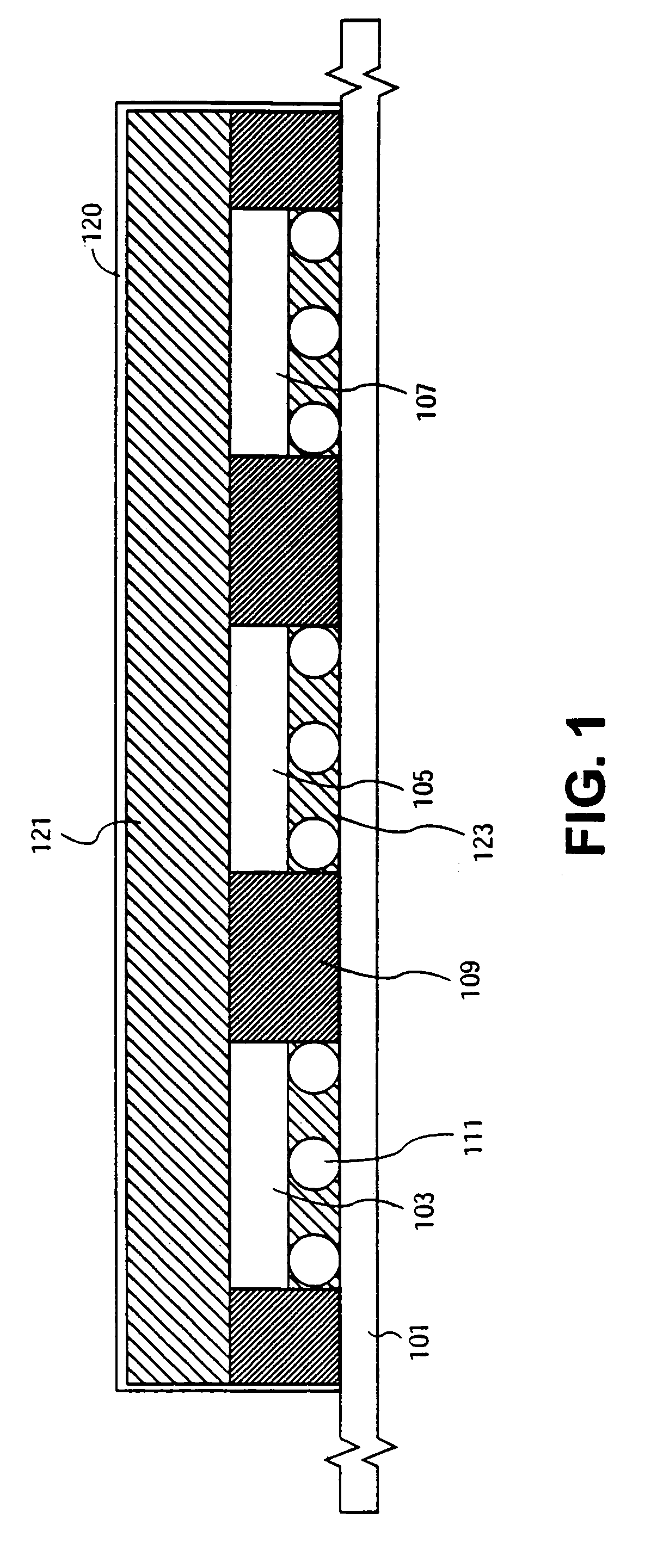

[0022]Referring to FIG. 1, a side view of an embodiment of the invention is shown having two separate mold flows. In one embodiment of the invention, the top mold flow 121 flowing between the top of the dice 103, 105, and 107 and the mold chase 120, and the bottom mold flow 123 between the dice 103, 105, and 107 and the package substrate 101, are kept separate by flow modifier 109. By splitting the mold flow into two separate mold flows using the flow modifier 109, the top mold flow 121 may be prevented from wrapping over the dice 103, 105, and 107. Without the flow modifier 109, the bottom mold flow 123 and the resulting overwra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com