Method for modeling color halftones

a color halftone and model technology, applied in the printing industry, can solve the problems of inflexibility of methods, large amount of memory required to store this type of models, and difficulty in accurate color prediction, so as to reduce the order of models and computations. the effect of complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

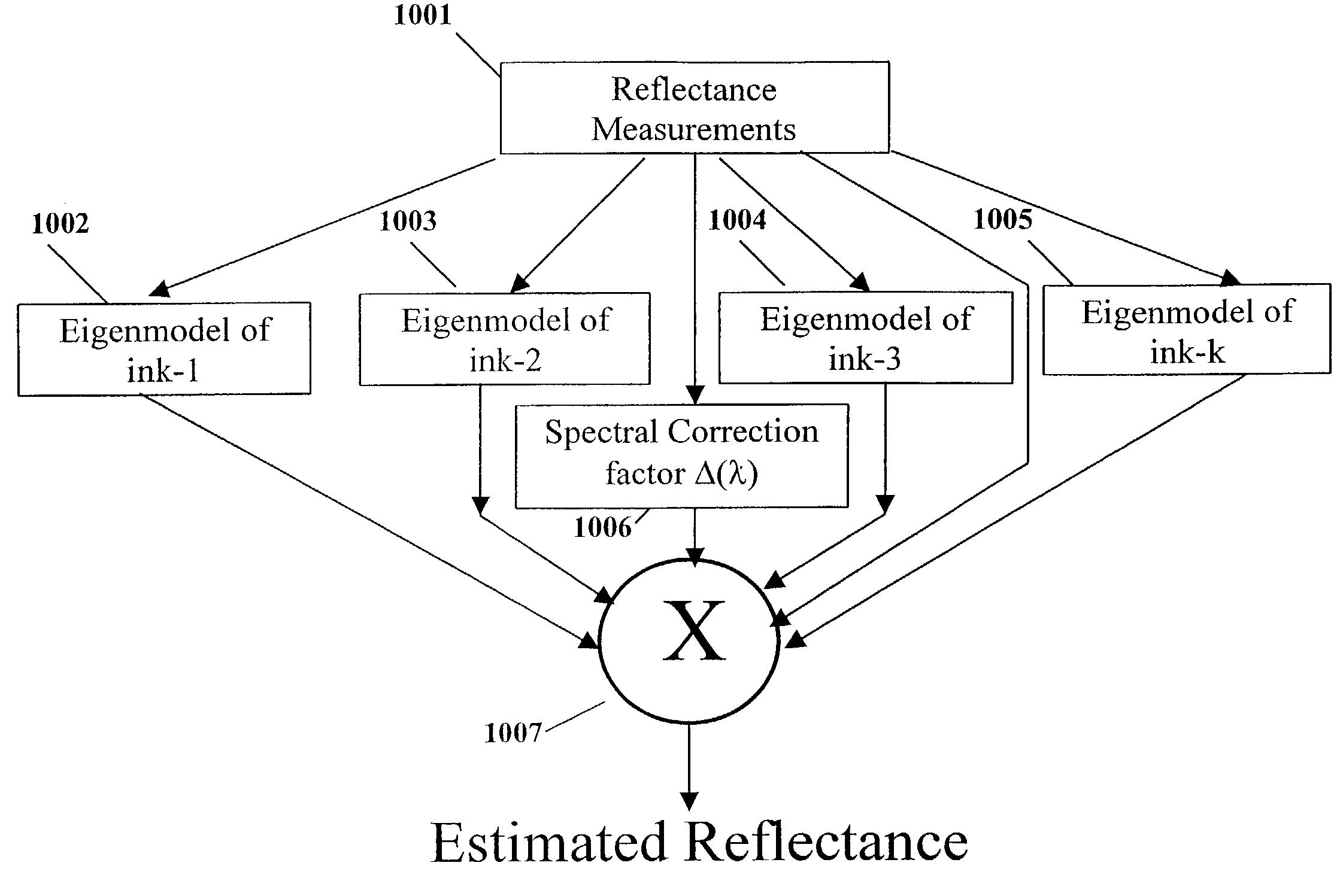

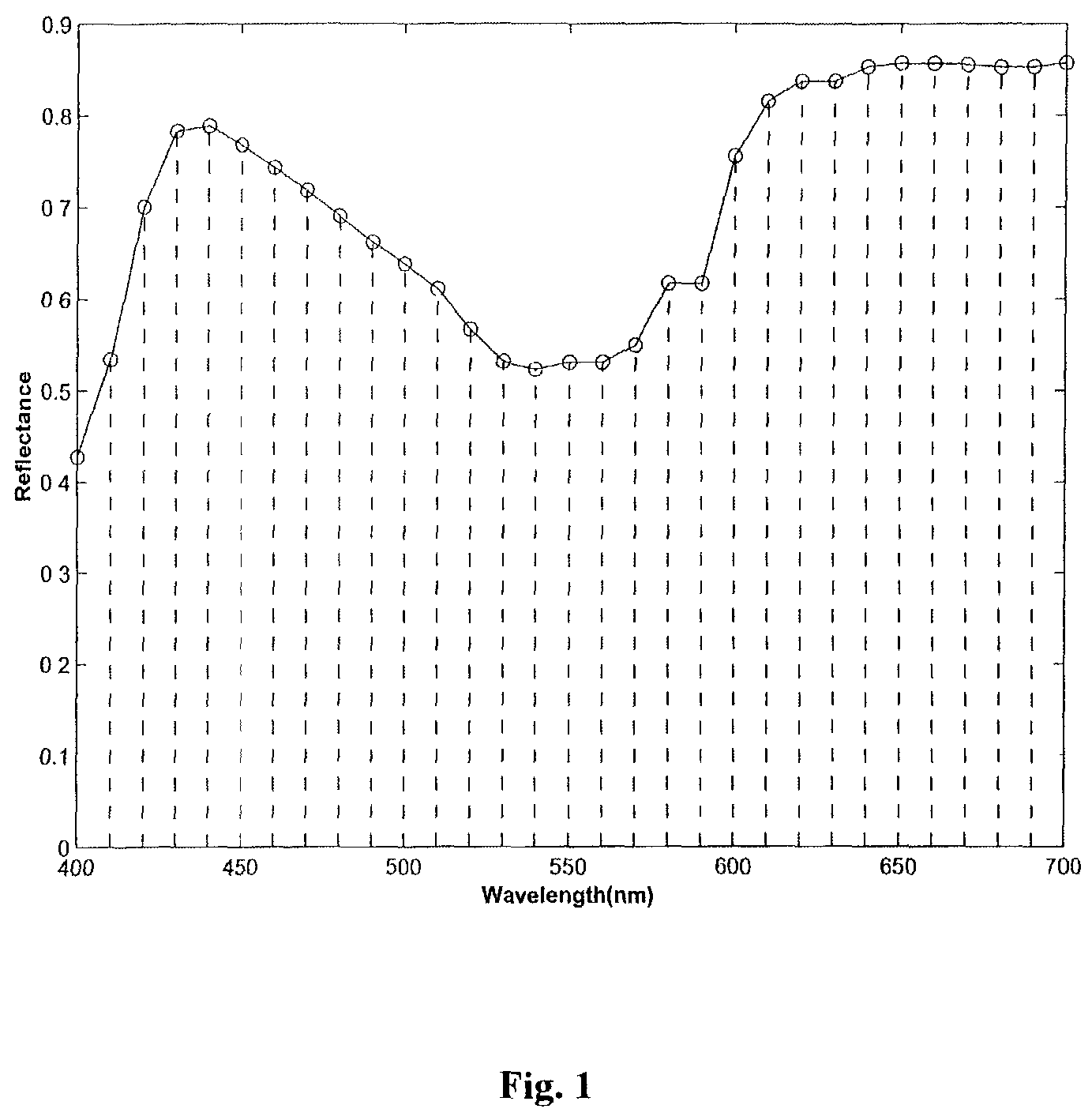

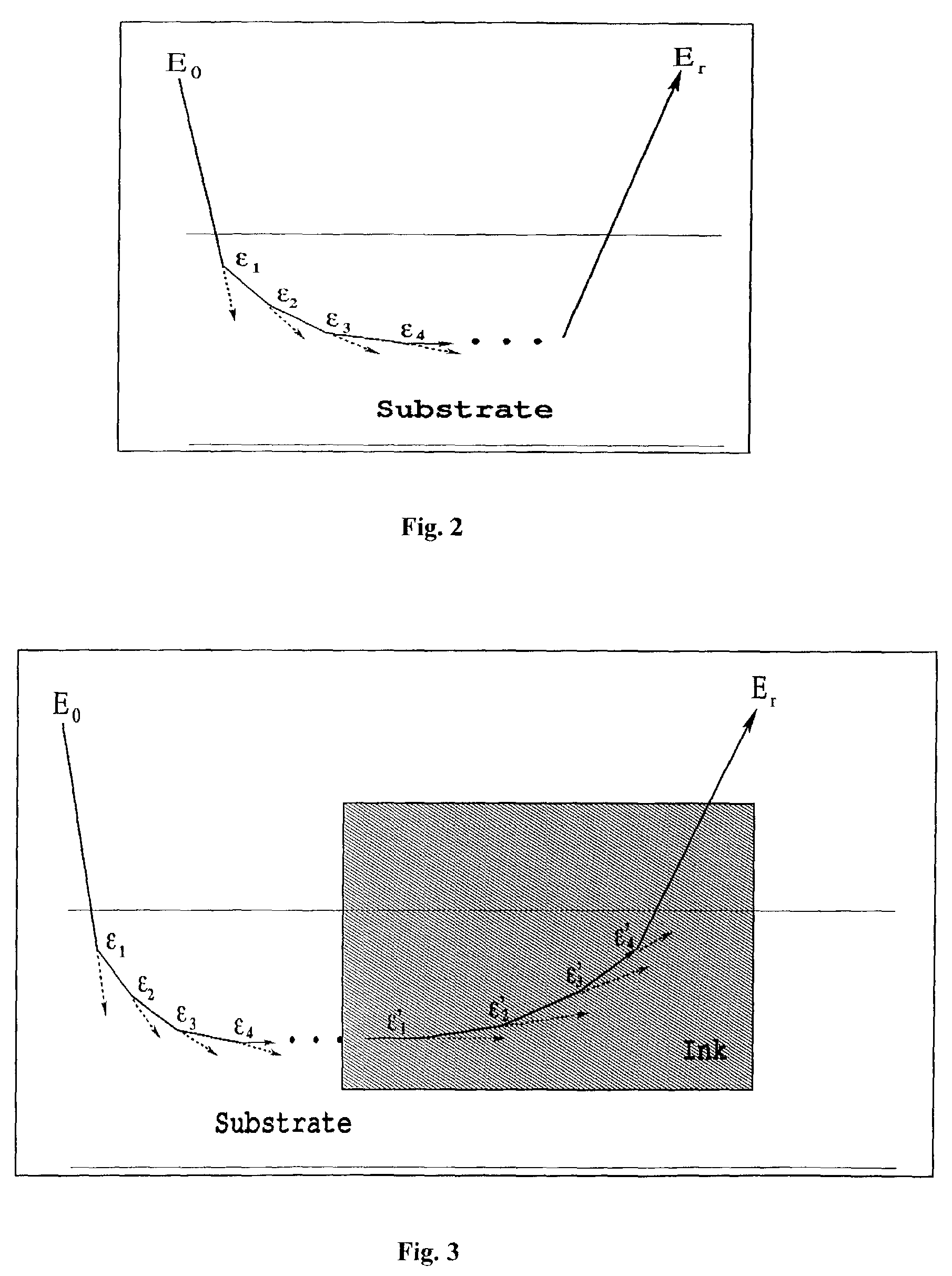

[0027]The method of the present invention is based on an eigenanalysis of color sample reflectance data and a simplifying probabilistic analysis. Unlike other background art methods involving probability theory, the method of the present invention considers the scattering of light on the paper substrate as a breakage process governed by a log-normal distribution. In this method the macro reflectance of a print color is a multiplicative composition of the primary reflectances in contrast to being to an additive mixture, as in the above-discussed background art. The method can be applied to clustered ordered dithering and to stochastic dithering, where for each case the eigenanalysis is performed by employing single ramp-ups of the primary colors (e.g., cyan, magenta and yellow). The method reduces both the number of parameters and the number of measurements required for printer characterization. For the case of two color mixtures, a maximum average color difference CIELab ΔE equal to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com