Modular electronics enclosure

a module and enclosure technology, applied in the direction of side-by-side/stacked arrangements, electrical apparatus construction details, cabinet/cabinet/drawer, etc., can solve the problems of reducing the packing efficiency of the enclosure, and affecting the use of the enclosure. , to achieve the effect of convenient use and assembly, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

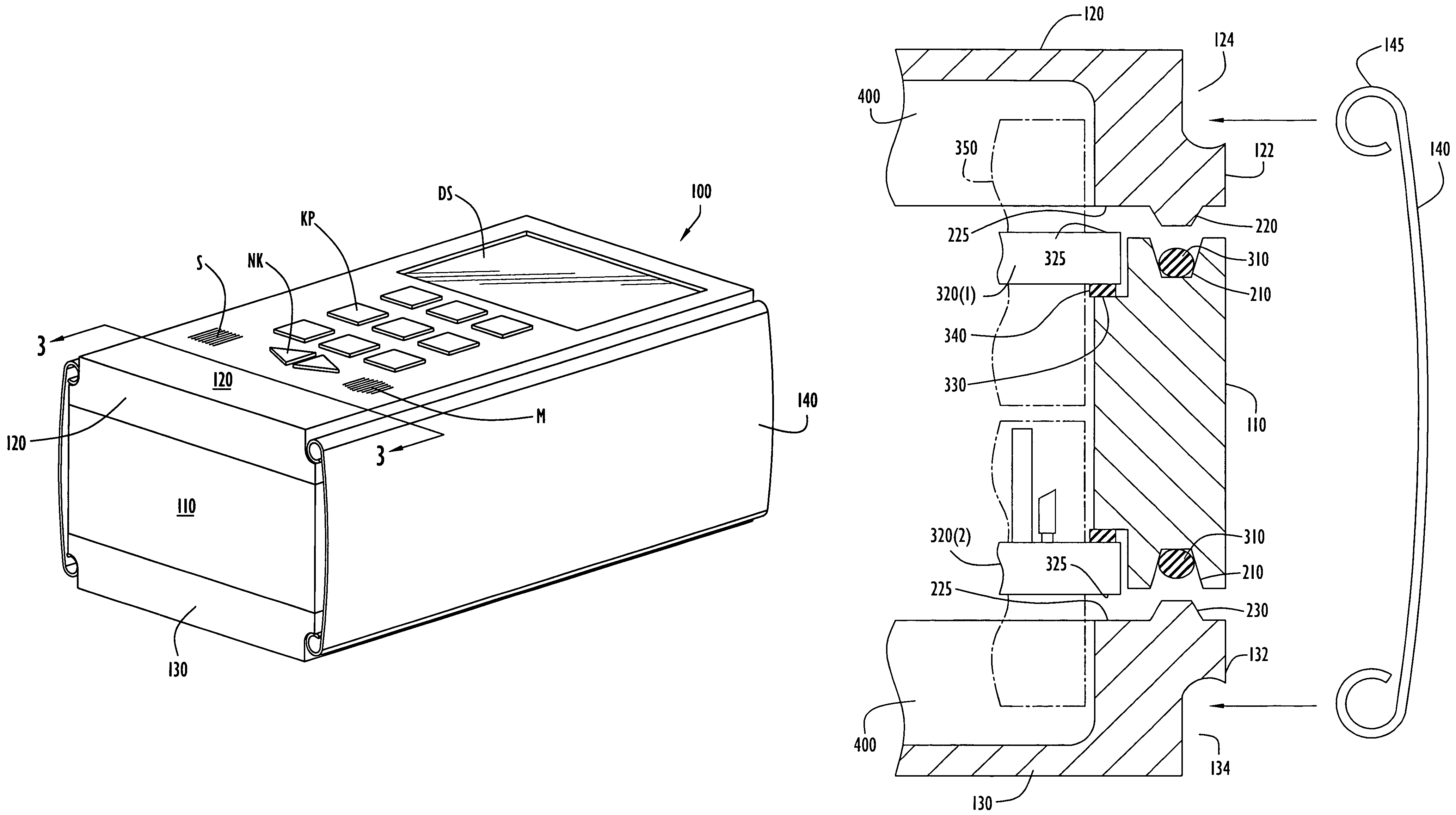

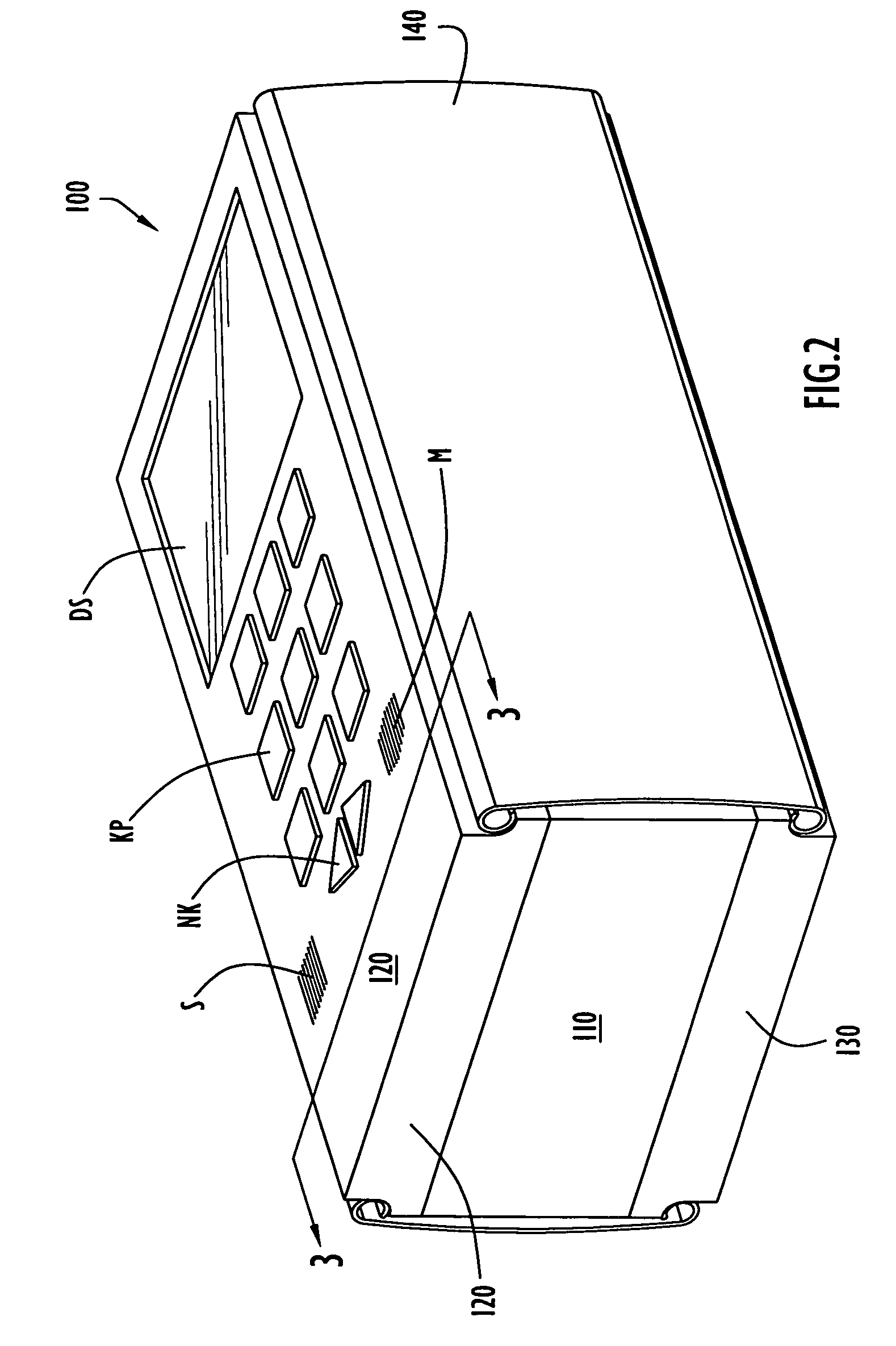

[0025]A modular electronics enclosure is provided having at least one intermediate section that engages substantially similar top and bottom lid members via complementary structures, such as tongue and groove structures. A spring biased clip clamps the top and bottom lid members to hold the entire enclosure together. The one or more intermediate sections are constructed to be interchangeable to increase or decrease the capacity of the modular enclosure, as well as allowing for profile specific designs.

[0026]FIG. 2 is a perspective view of an embodiment of modular enclosure 100. Modular enclosure 100 comprises an intermediate support section or member 110 that supports at least one circuit card assembly (CCA), a top lid member 120 and bottom lid member 130. A clip 140 engages the top 120 and bottom 130 to secure the intermediate section 110 in a sandwich arrangement. Two clips 140 are shown that engage opposite sides of the top lid 120 and bottom lid 130. The clips 140 are an example...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com