Socket with integrated insulation displacement connection terminals

a technology of displacement connection and socket, which is applied in the direction of coupling device connection, coupling device details, contact members penetrating/cutting insulation/cable strands, etc. it can solve the problems of non-uniform exertion on idc terminals, inconvenient operation, and further affecting the working efficiency of wiring operation, so as to improve the assembling efficiency of signal communication socket and effectively prevent wires from being stripped off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]In order to make the aforementioned and other objects, features, and advantages of the present invention be comprehensible, preferred embodiments accompanied with figures are described in detail below.

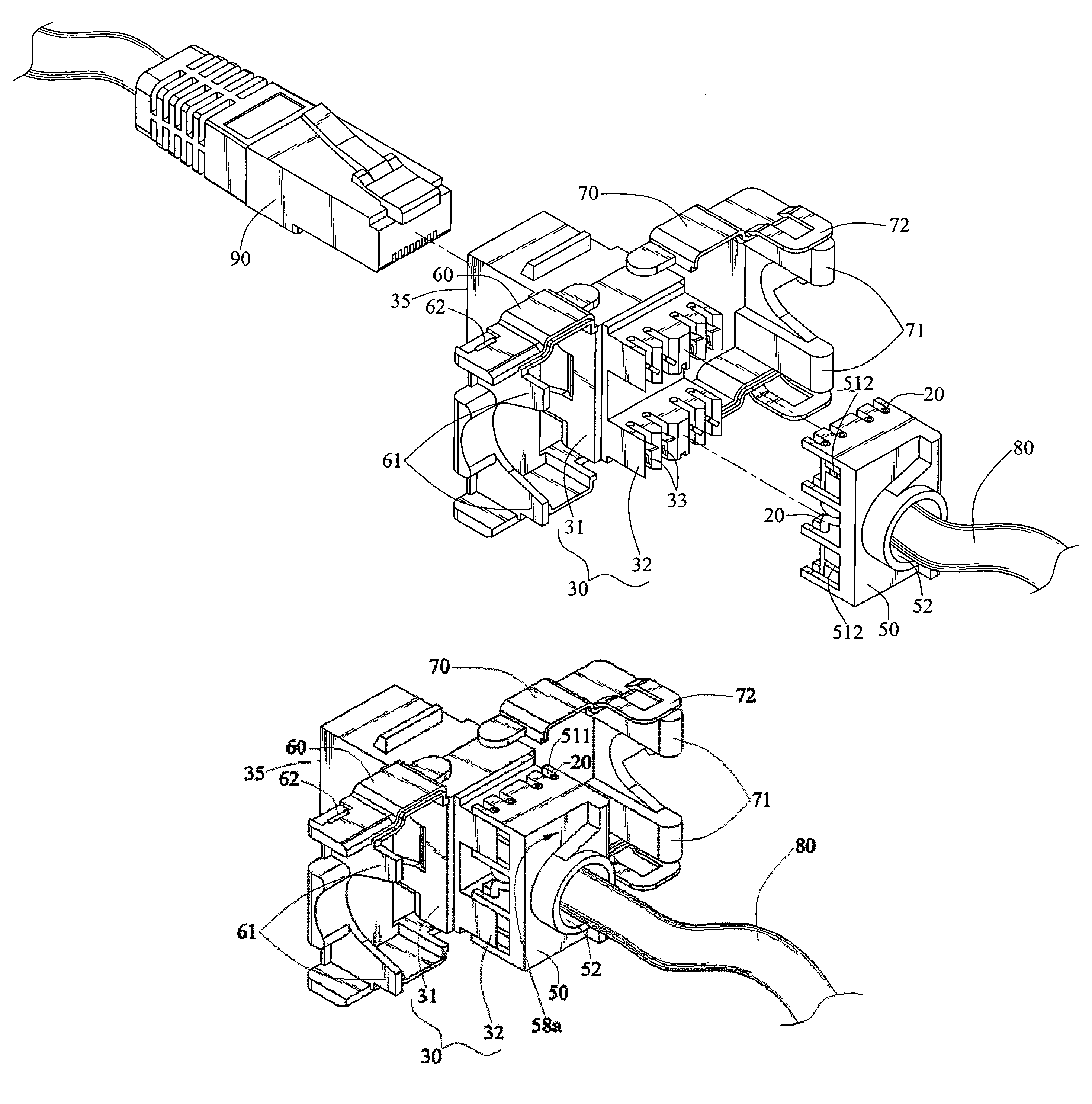

[0026]Referring to FIGS. 4, 5, 6, and 7, a socket with integrated insulation displacement connection terminals according to an embodiment of the present invention is provided. A plurality of wires 20 stranded into a cable 80 is able to be connected to the socket, so as to electrically connect the wires 20 to a plug 90 inserted into the socket. The socket includes a base 30, a terminal pusher 50, a first pressing element 60, and a second pressing element 70.

[0027]The base 30 has a housing 31, a terminal block 32, and twos of insulation displacement connection terminals 33 (IDC terminals). The base 30 further has a recess 35 formed on the front side of the terminal block 32 for receiving a plug 90 to be inserted therein. The terminal block 32 is mounted to the housing 31, and has t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com