Dummy hard disk drive

a hard disk drive and a sleeve technology, applied in the direction of instruments, paper/cardboard articles, electrical apparatus casings/cabinets/drawers, etc., can solve the problem of space was

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014]The disclosure, including the accompanying drawings, is illustrated by way of examples and not by way of limitation. It should be noted that references to “an” or “one” embodiment in this disclosure are not necessarily to the same embodiment, and such references mean at least one.

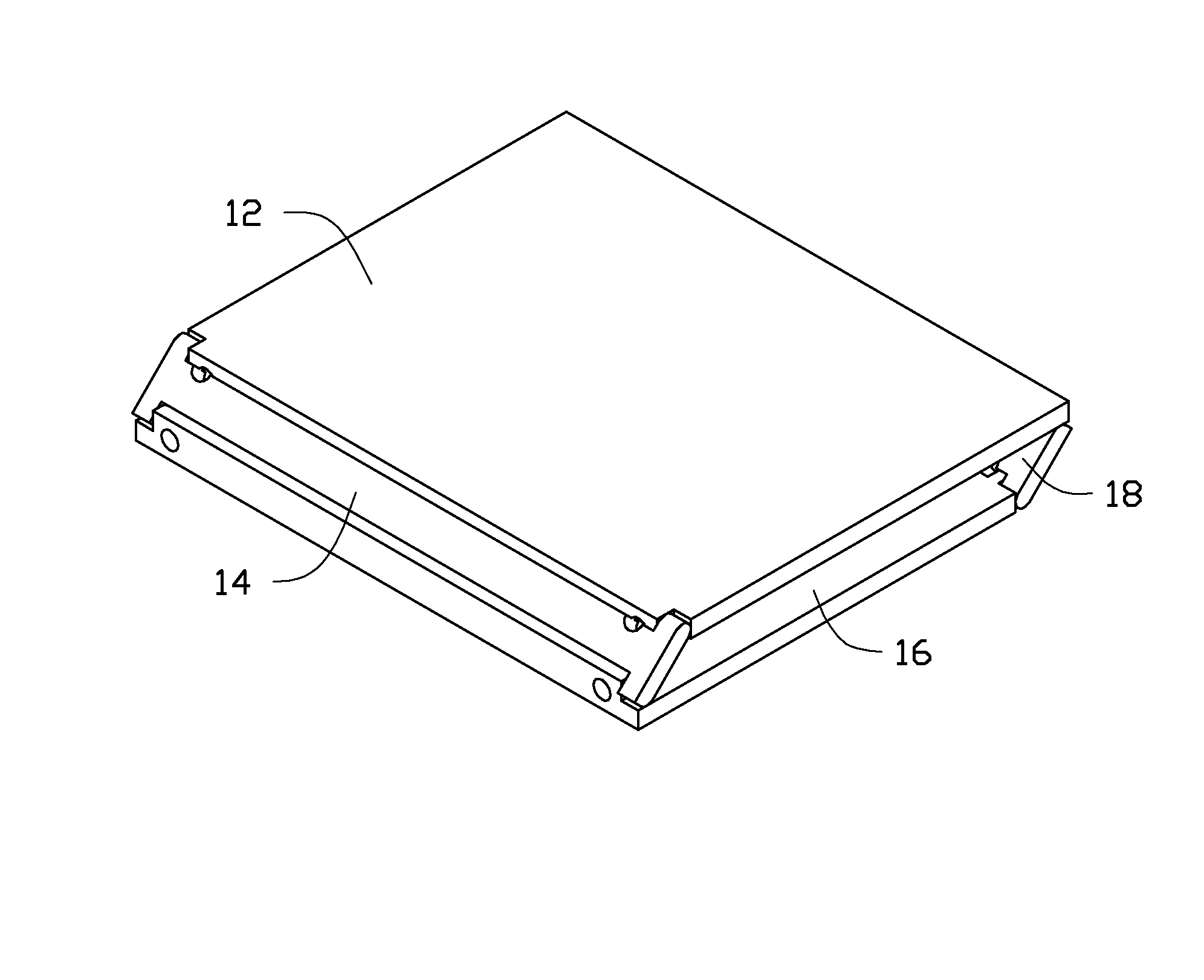

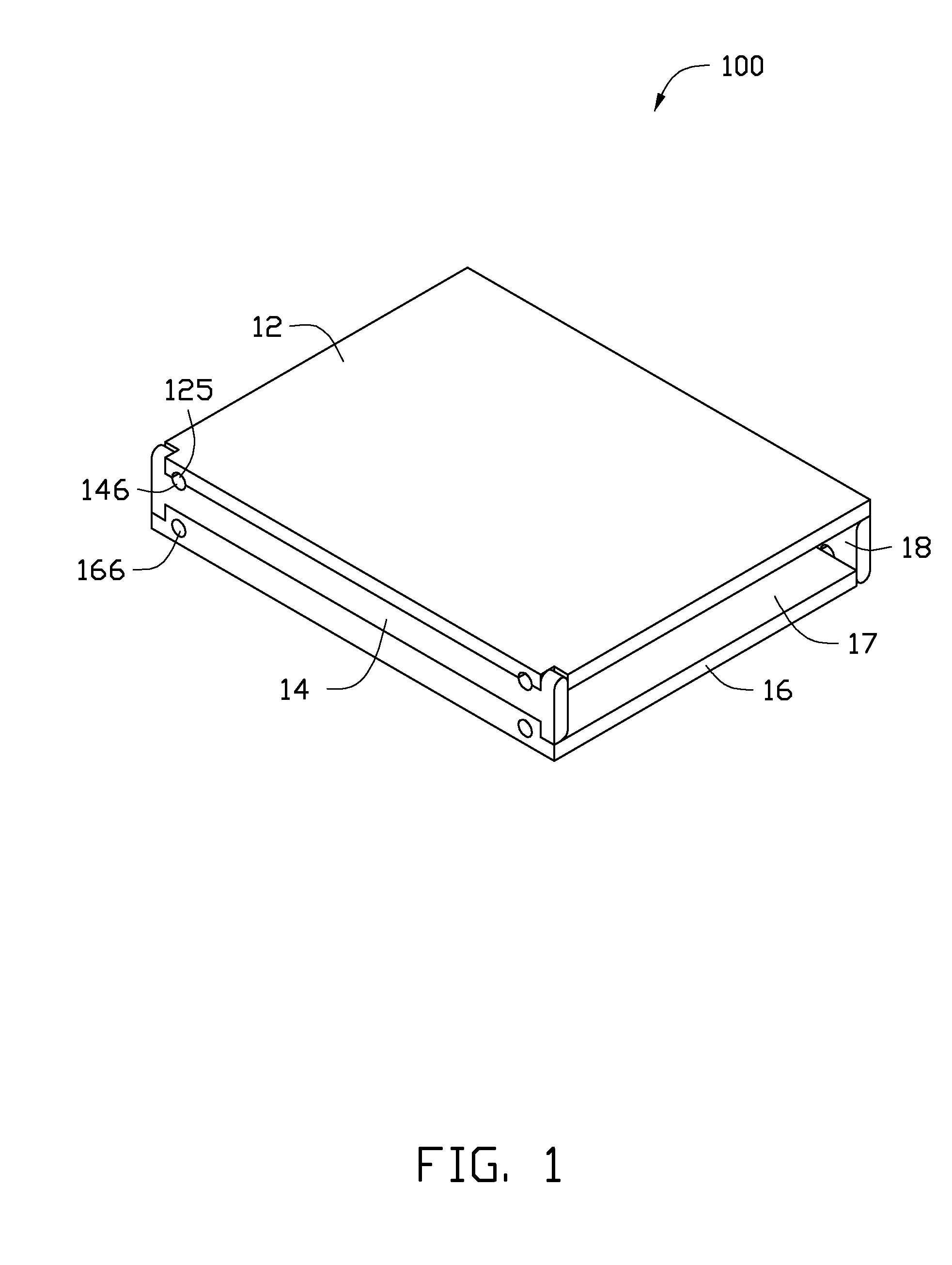

[0015]Referring to FIG. 1, an embodiment of a dummy hard disk drive (HDD) 100 includes a top plate 12, a first side plate 14, a bottom plate 16, and a second side plate 18. The top plate 12 is parallel to the bottom plate 14. The length and width of the top plate 12 and the bottom plate 16 are the same as those of an actual HDD. The first side plate 14 is parallel to the second side plate 18. The top plate 12, the first side plate 14, the bottom plate 16, and the second side plate 18 are made of resilient material, such as rubber or plastic.

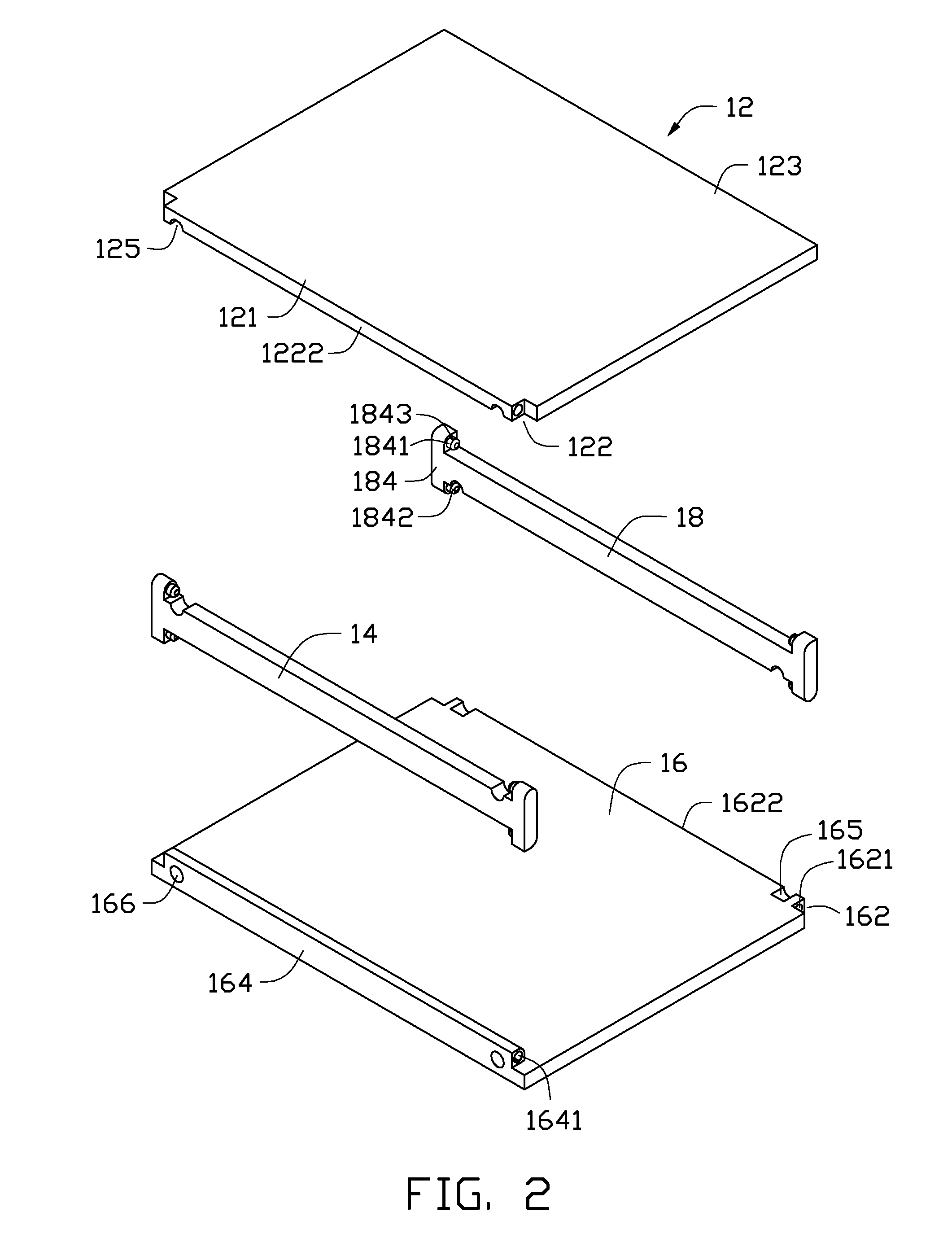

[0016]Referring to FIGS. 2-5, two cutouts 122 are defined in opposite ends of a first side 121 of the top plate 12. The first side 121 forms a flange 1222 between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com