Double shell dispenser

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

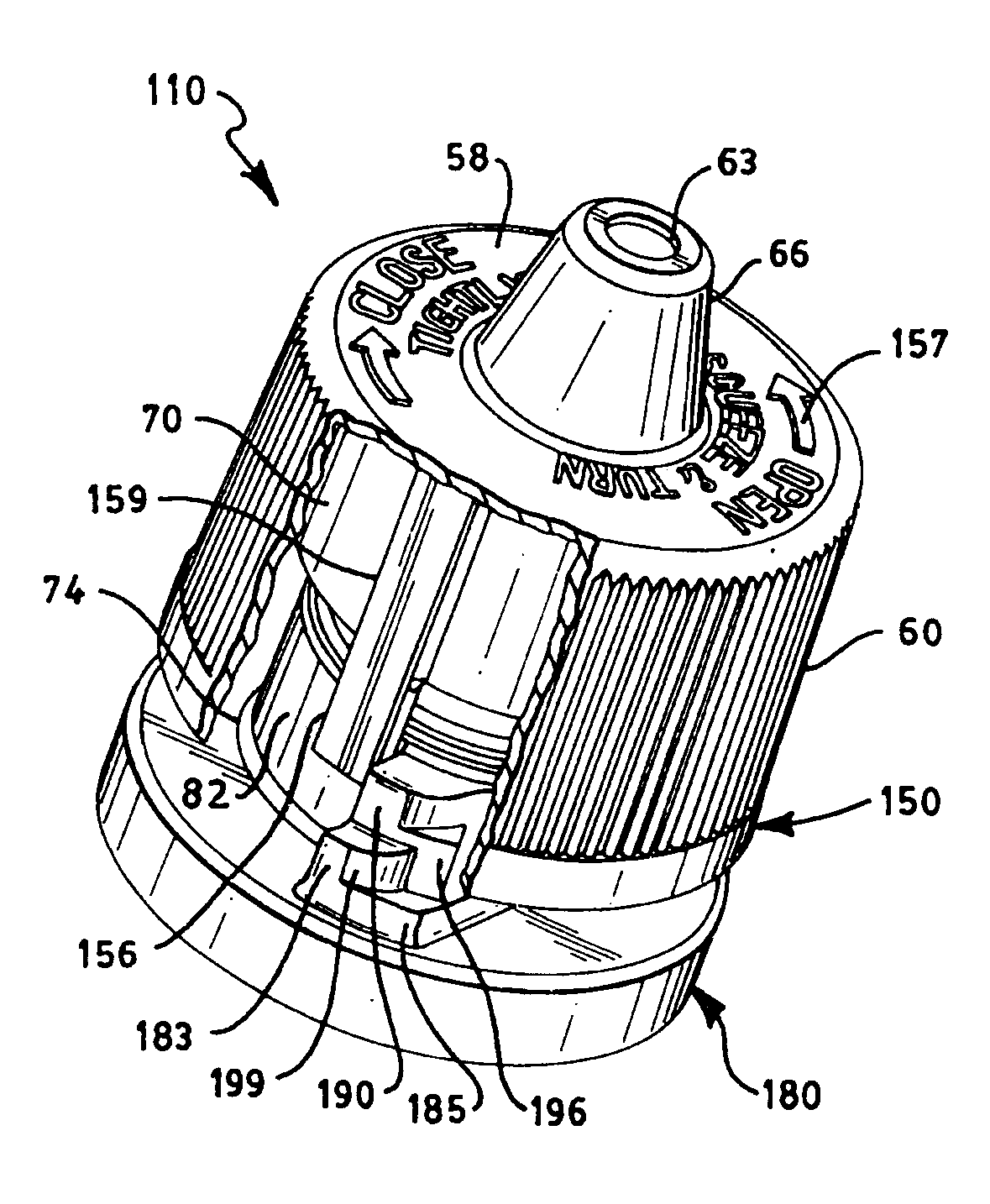

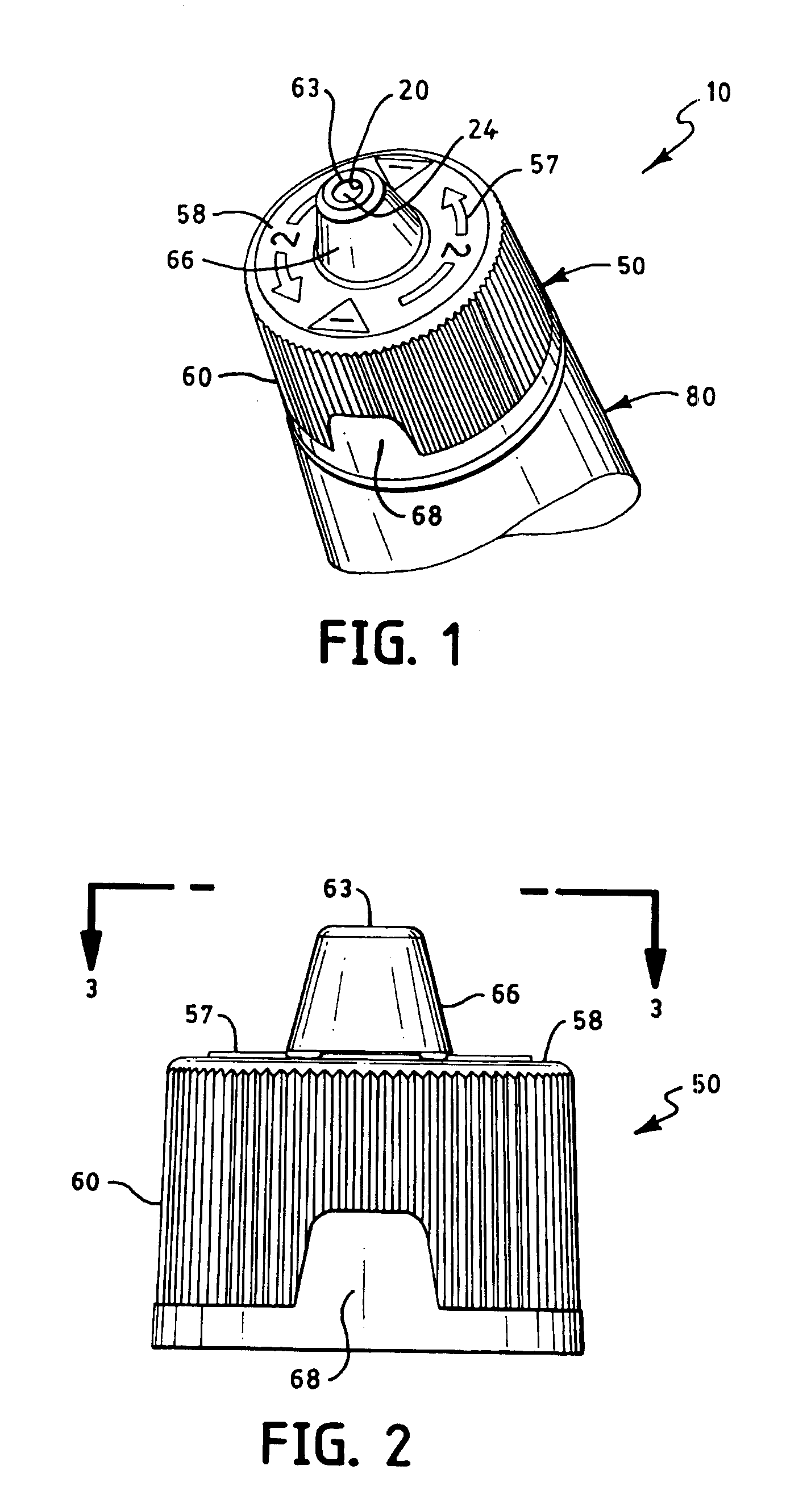

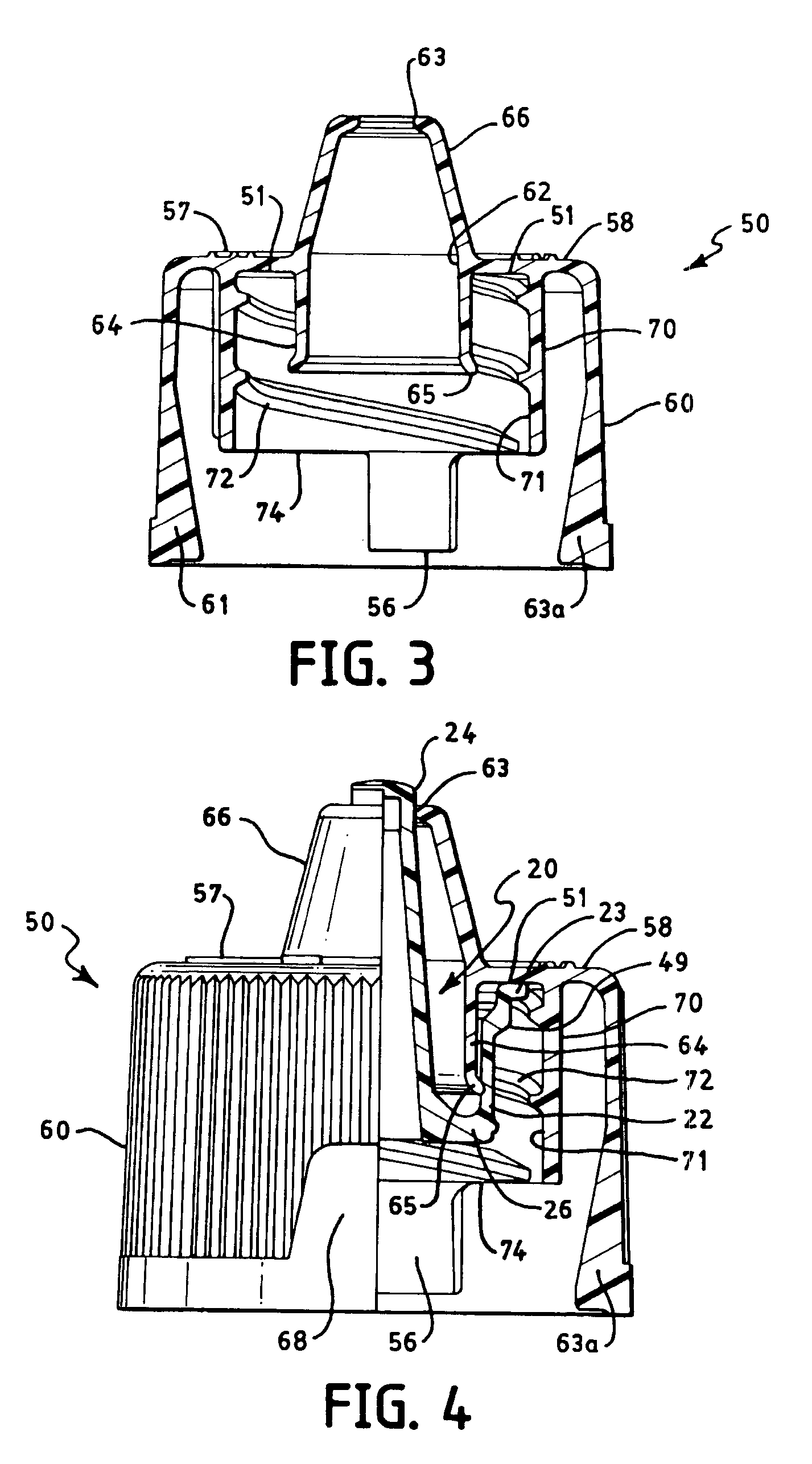

[0022]As shown in the FIGS. 1-13, a closure of the present invention is provided having a dispensing feature with a stopping mechanism which facilitates the dispensing of the contents of a tube, bottle or similar container, but prevents removal of the closure from the container. Closure 10 may be formed of any material well known in the art, such as polypropylene and polyethylene. As shown in FIG. 1, the closure 10 includes a cap body 50, a fitment 20 and a container finish 80. The cap body 50 is threadably attached to the container finish 80, so that the cap body 50 may threadably rotate axially along the neck portion 82 of the container finish 80. In this manner, the cap body 50 may be rotated from a closed position to an open position in order to access the contents of the container (not shown) upon which the container finish 80 is disposed. The fitment 20 is positioned within closure 10 so that the opening 63 in the spout portion 66 of the cap body 50 is sealed by the post 24 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com