Method and apparatus for pluggable fiber optic modules

a fiber optic module and plug-in technology, applied in the field of fiber optic modules, can solve the problems of increasing the cost affecting the operation of fiber optic transceivers, and requiring additional components for using separate optical elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

second embodiment

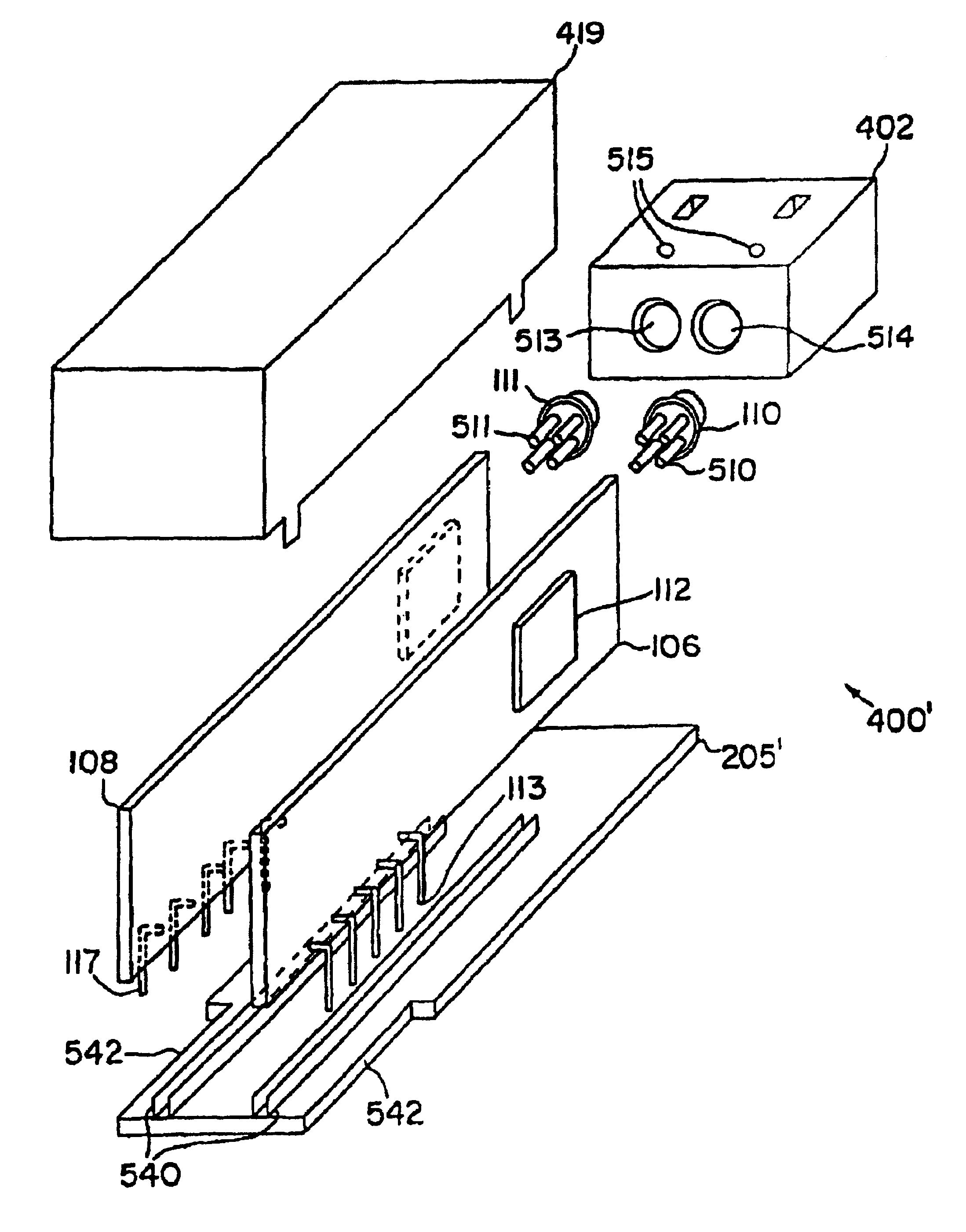

[0065]The embodiments of the invention include a method, apparatus and system for vertical board construction of fiber optic transmitters, receivers and transceivers. Briefly, fiber optic transmitter and receiver electrical elements are implemented on at least two separate printed circuit boards (PCBs) in a fiber optic module. The separate boards are arranged within the fiber optic module to reduce the footprint of the fiber optic module. In one embodiment, bending light or photons through ninety degrees, the light transmitter (a packaged type of emitter) and a light receiver (a packaged type of photodetector) are each mounted substantially perpendicular to the transmit and receive boards respectively such that their active areas are nearly facing each other but offset. A single optical block can be used to implement lenses and reflecting surfaces to minimize manufacturing costs. In one embodiment, the light receiver and light transmitter are mounted offset from each other in the op...

first embodiment

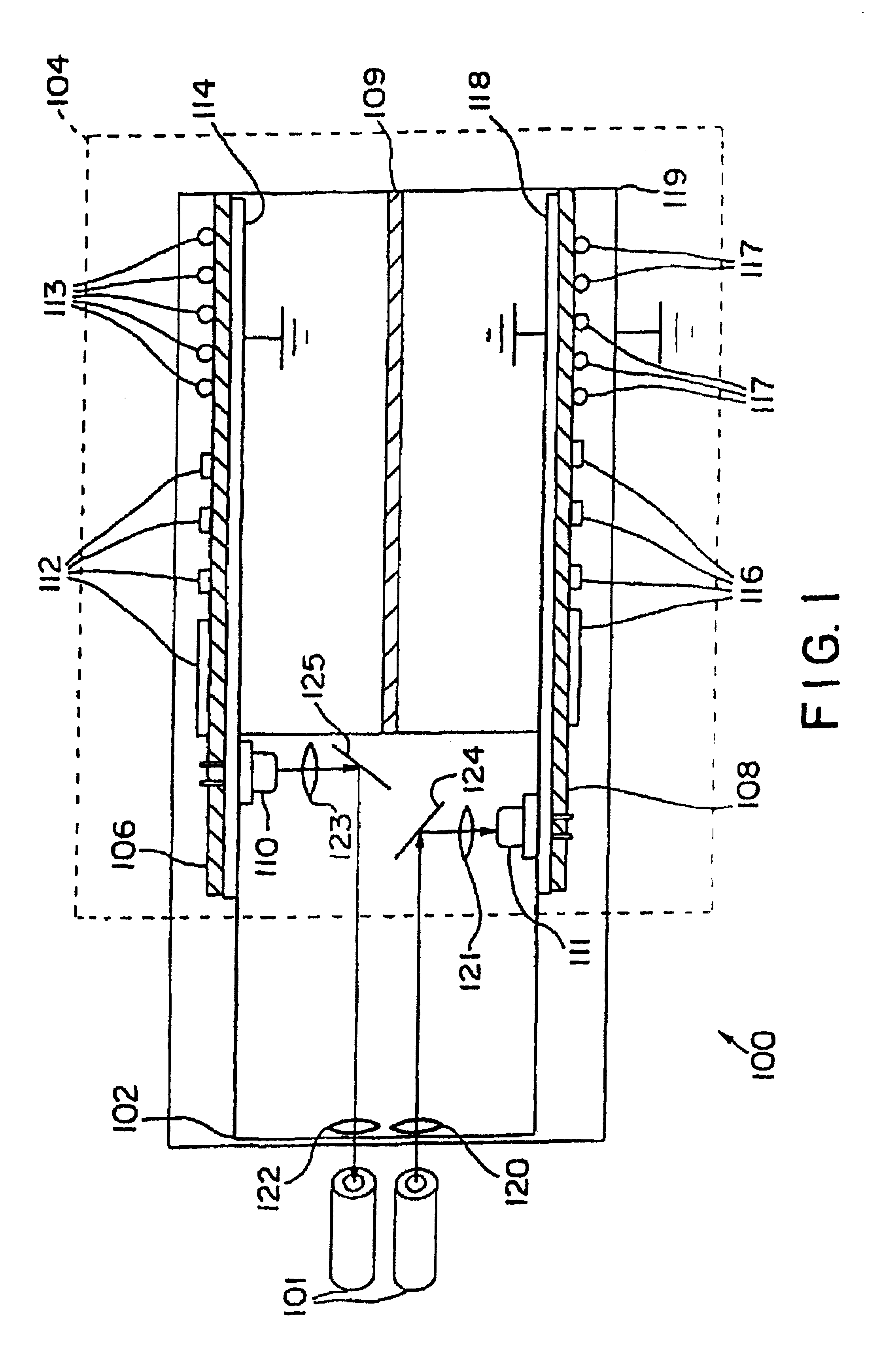

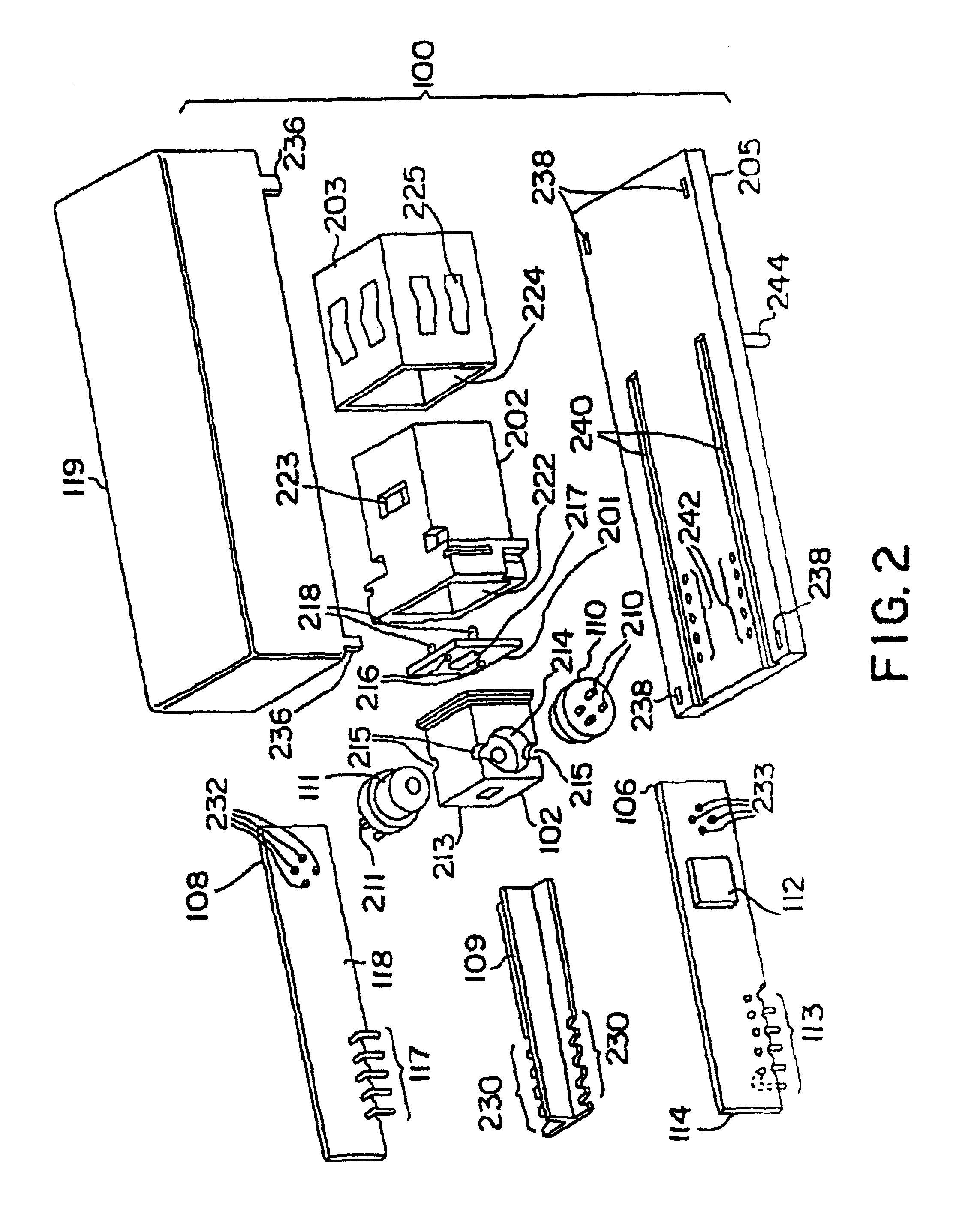

[0066]Referring now to FIG. 1, a simplified cutaway view of the invention is illustrated. FIG. 1 illustrates a fiber optic module 100 coupling to a pair of fiber optic cables 101. Fiber optic module 100 includes an optical block 102 and an electrical element 104. The optical block 102 may also be referred to as a nose, an optical port, an alignment block, an optical connector, an optical receptacle or receptacle. The optical block 102 can interface to an optical connector such as an LC, MT-RJ or VF-45 optical connector. The electrical element 104 includes a transmit printed circuit board (PCB) 106, a receive PCB 108, an optional internal shield 109, a light transmitter 110, a light receiver 111, and a shielded housing or cover 119. The light transmitter 110 and light receiver 111 are optoelectronic devices for communicating with optical fibers using light of various wavelengths or photons. An optoelectronic device is a device which can convert or transduce light or photons into an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com