Arc suppressing room of low voltage breaker

A low-voltage circuit breaker and arc-extinguishing chamber technology, applied in the field of arc-extinguishing chambers, can solve the problems of unfavorable mass production, unsatisfactory arc-extinguishing performance, difficult installation and positioning of metal plates and side walls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

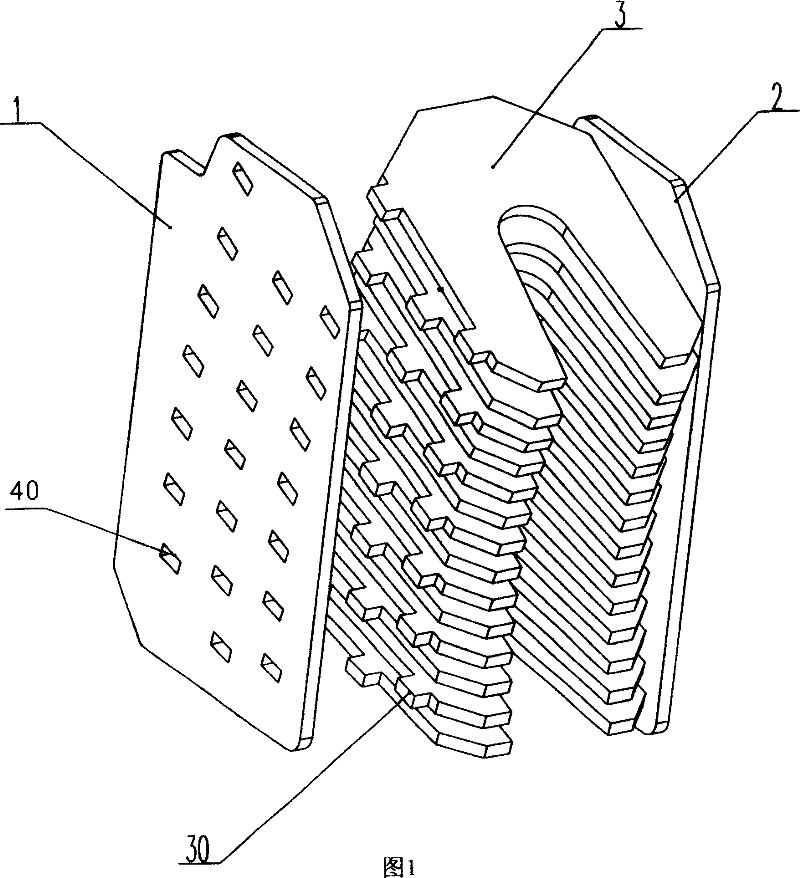

[0023] Figure 1 shows a prior art arc extinguishing chamber. It can be seen from the figure that the “U”-shaped metal plate 3 has a plurality of sets of protrusions 30 on both sides of the edge, which cooperate with the corresponding openings 40 on the side walls 1 and 2, Due to the many and scattered matching points, the requirements for processing accuracy are quite high, and it also makes assembly difficult. Secondly, the arc extinguishing chamber is open, it is difficult to form a standard module, and it is impossible to carry out modular mass production.

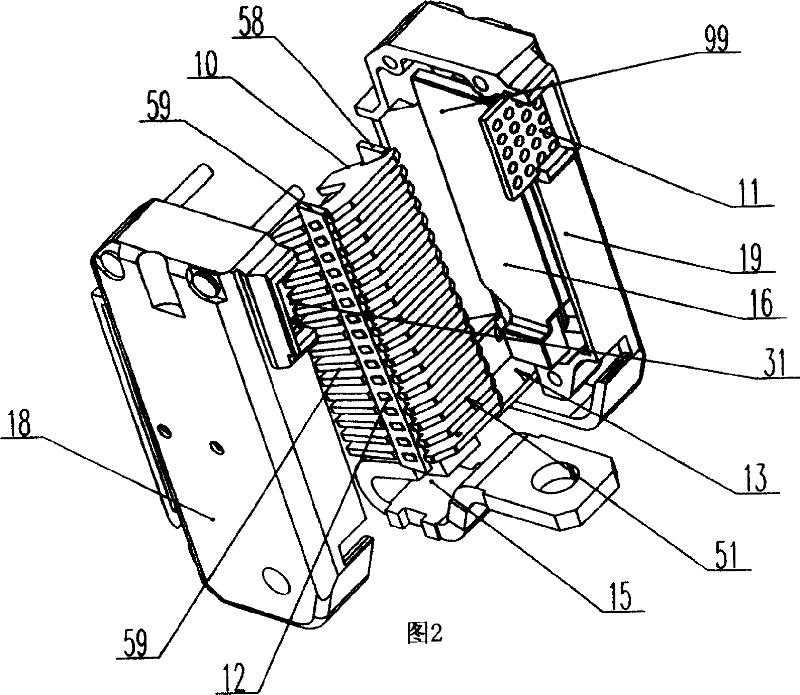

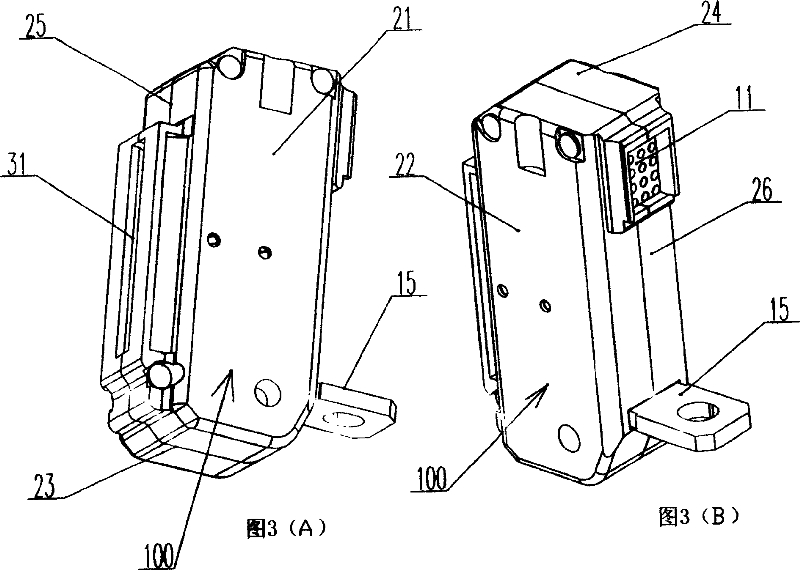

[0024] Referring to Figures 2, 3(A) and 3(B), the arc extinguishing chamber of the present invention includes an arc extinguishing device 51 composed of a plurality of "U"-shaped metal plates 10, and the plurality of metal plates 10 is fixed by a pair of connecting strips 12 on both sides; the arc extinguishing device 51 is encapsulated in a box-shaped housing 18, 19 made of insulating material by riveting. The housing is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com