Biological material separator

A technology for separators and materials, applied in the field of biological material separators, which can solve the problems of endangering human health, corruption, and the existence of pathogenic bacteria, and achieve the effects of guaranteed utilization, reasonable treatment, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

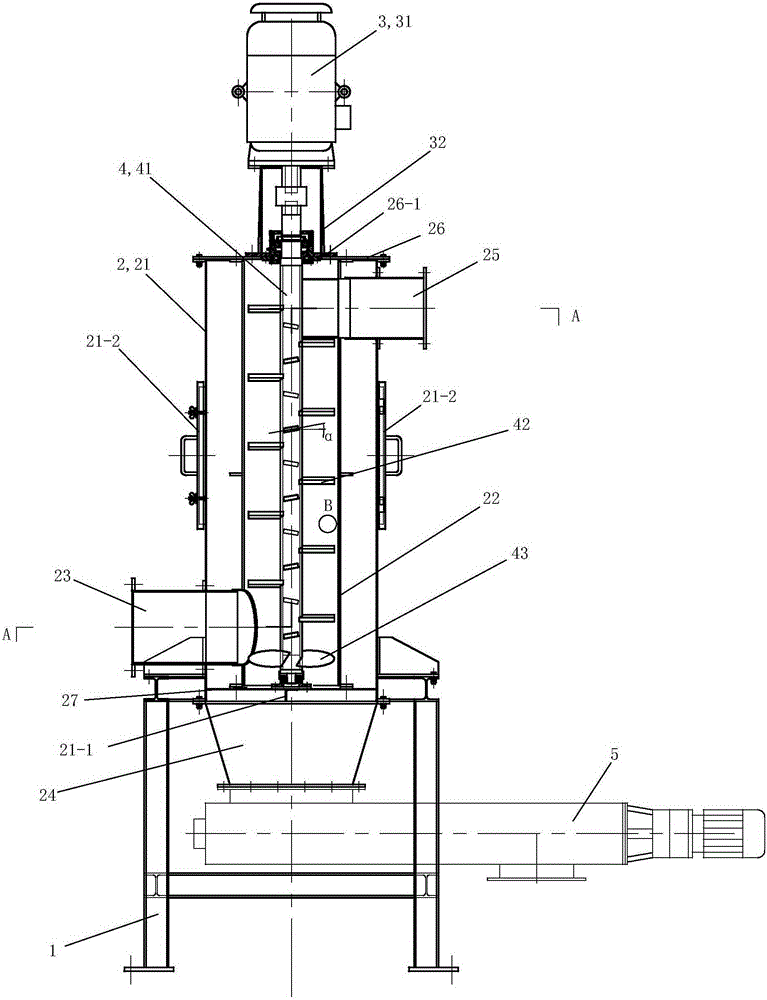

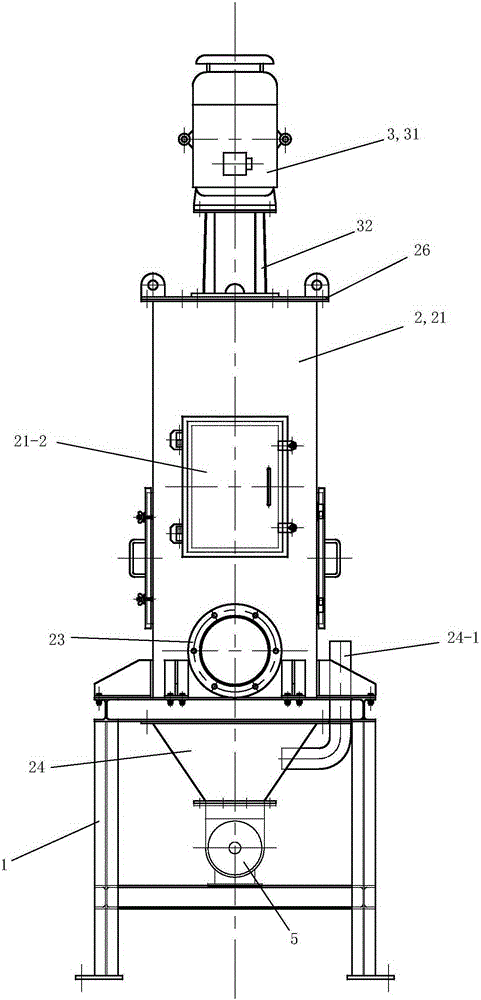

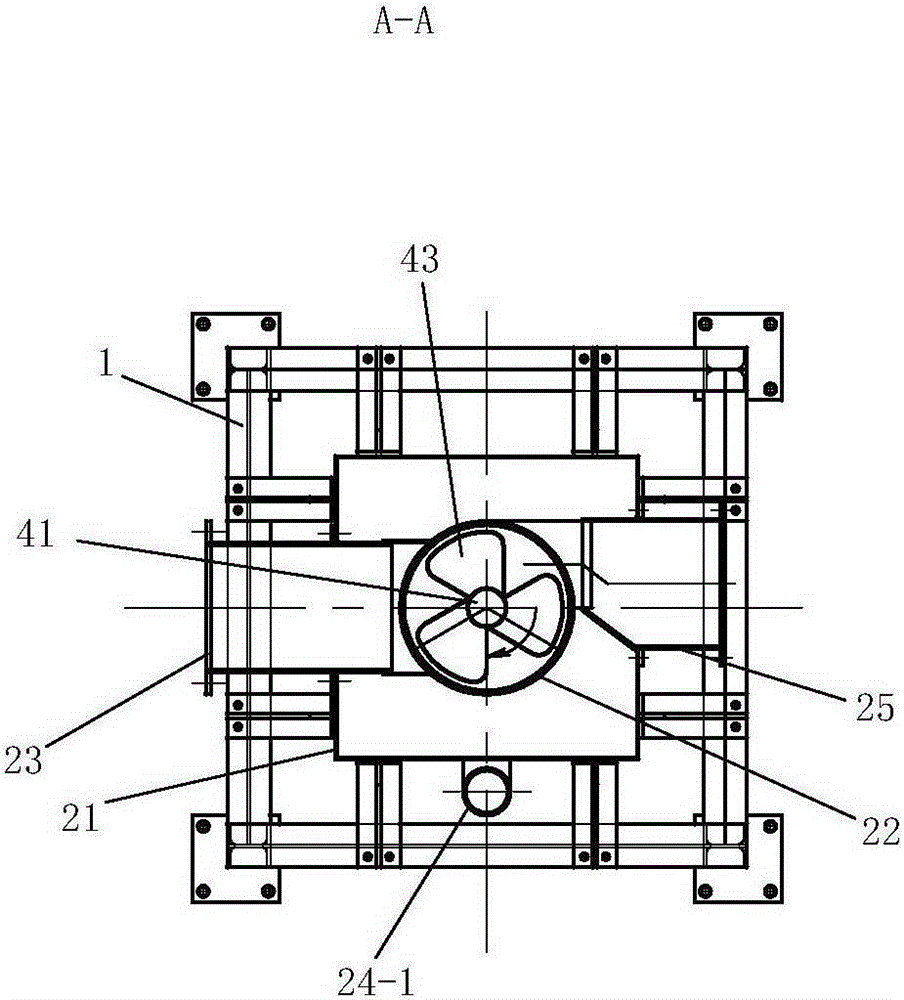

[0028] See Figure 1 to Figure 3 , The biological material separator of the present invention includes a main frame body 1, a main cylinder body 2, a power unit 3, a crushing and separating device 4 and a discharge machine 5.

[0029] See figure 1 and figure 2 The main frame body 1 is welded and fixed by I-beams to form a frame structure, and the main frame body 1 is fixedly arranged on the ground.

[0030] See Figure 1 to Figure 3 , The main cylinder 2 includes an outer cylinder 21 , an inner cylinder 22 , a feed port 23 , an organic matter discharge port 24 , an upper discharge port 25 , an upper cover plate 26 and a lower bottom plate 27 . The outer cylinder 21 is vertically fixedly arranged on the main frame body 1 through its flange located at the lower end. A set of reinforcing ribs is provided between the lower periphery of the outer cylinder 21 and the main frame body 1 . The inner lower end of the outer cylinder 21 is provided with an inner cylinder frame 21-1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com