Multi-flavor melon seed peeling frying pan and multi-flavor melon seed peeling frying method

A technology for melon seeds and frying pan is applied in the field of peeling frying pans for multi-flavored melon seeds and their peeling and frying. High efficiency and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

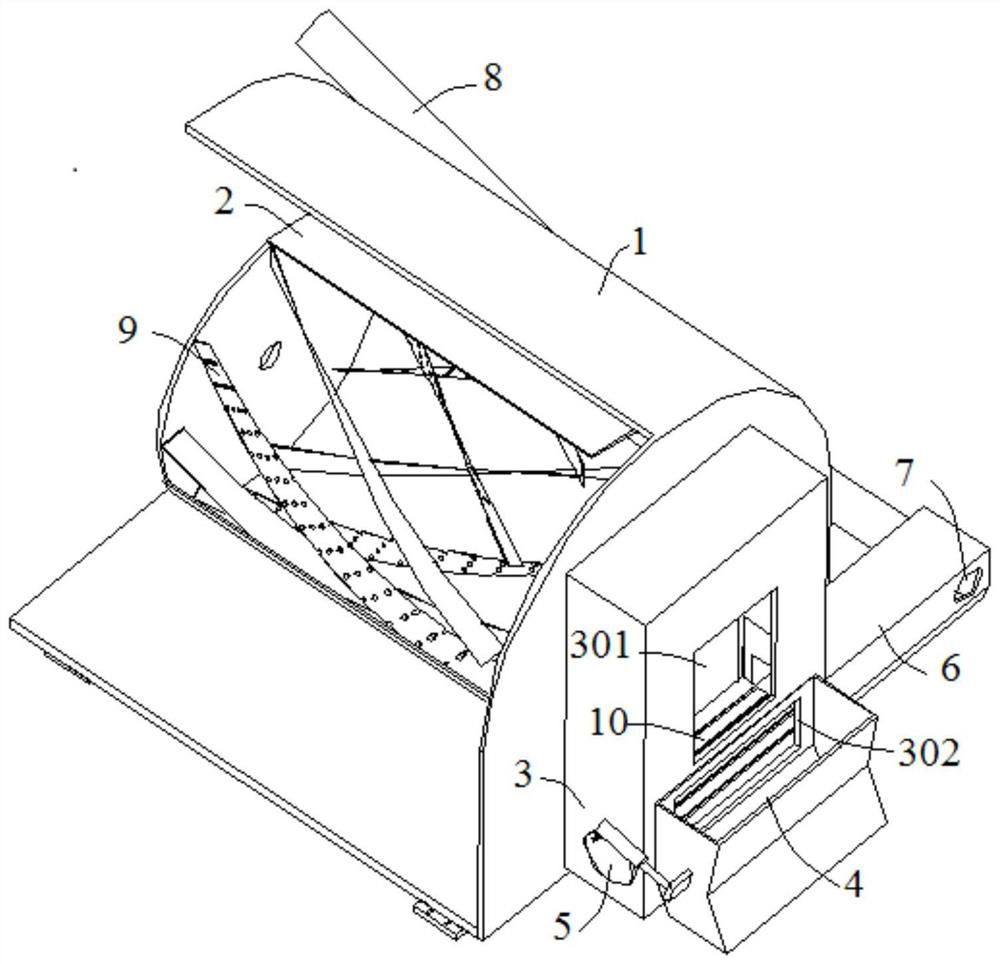

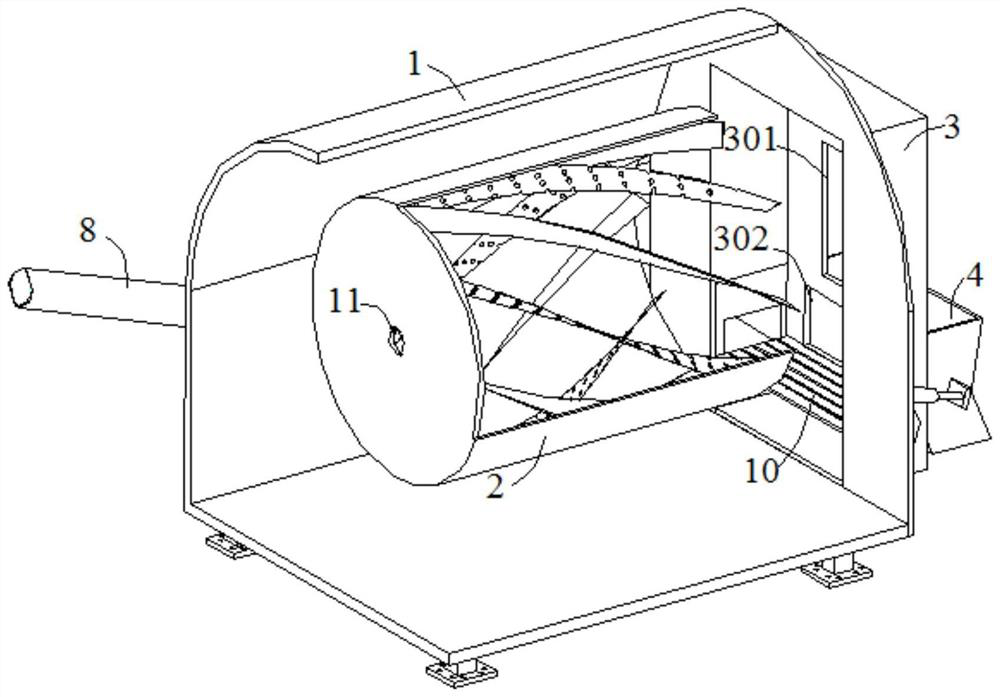

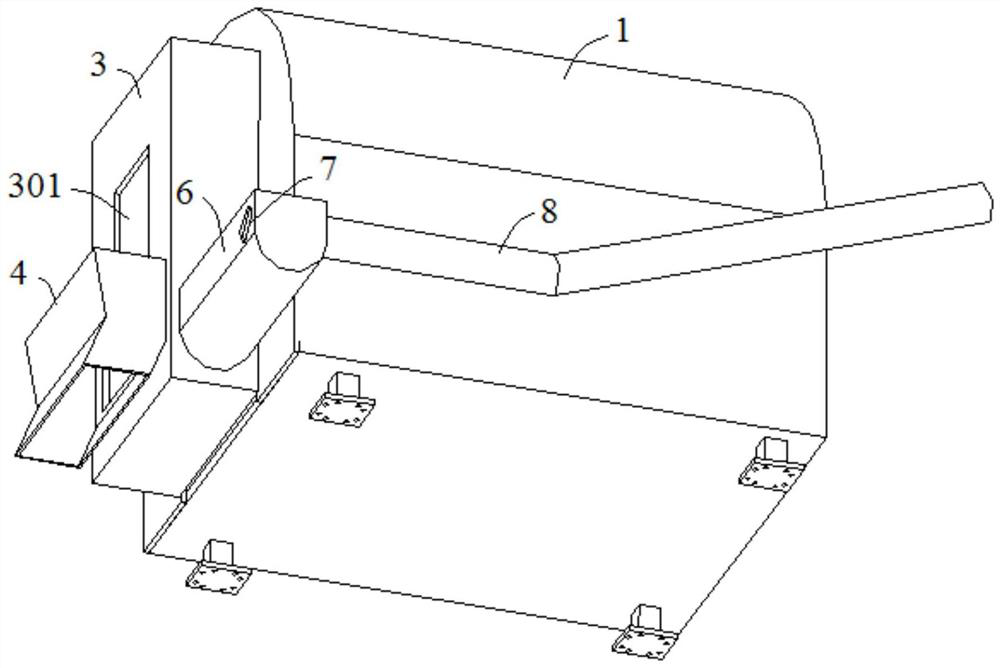

[0041] Such as figure 1 As shown, a frying pan for peeling multi-flavored melon seeds in this embodiment includes an outer furnace shell 1 and an inner furnace cylinder 2, and the inner furnace cylinder 2 is rotatably installed in the outer furnace shell 1 for frying melon seeds. The rear part of the outer furnace shell 1 is provided with a hot air circulation mechanism, the air outlet of the hot air circulation mechanism communicates with the inner furnace drum 2 , and its air suction port communicates with the inner furnace drum 2 or the outside air respectively. By setting a hot air circulation mechanism at the rear of the outer furnace shell, the hot air in the furnace can be drawn out and then circulated into the inner furnace barrel 2 as required, and the melon seeds can be fried by using the hot air in the furnace, which shortens the time for frying and makes the skin of the melon seeds more dusty. It is easy to remove, and its production efficiency is higher, and the r...

Embodiment 2

[0048]A method for peeling and frying multi-flavored melon seeds in this embodiment adopts the multi-flavored melon seeds peeling wok described in Example 1. Pour the hopper into the inner furnace tube 2 of the peeling frying pan. Before pouring in, open the combustion stove at the bottom of the outer furnace shell 1 to heat the frying pan. Control the feeding temperature at 135°C-145°C. At ~145°C, pour the melon seeds into the pot. Since the melon seeds are cold, the temperature in the furnace will drop rapidly, and then gradually rise in temperature during frying; In the range of ℃~142℃, the whole melon seeds out of the pot are close to the best state at this time, the skin is smooth and clean, and the inner kernels are fragrant and crispy. Preferably at 140°C; simultaneously open the hot air circulation mechanism and the dust removal system, open the hot air circulation mechanism, adjust the second operating handle 21 to rotate the inner windshield 22, open the hot air pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com