Processing method for oil-fried potato instant food

A technology of convenience food and processing method, applied in food science and other directions, can solve the problems of difficult processing, poor stickiness of potato starch, difficult to maintain flour processing characteristics, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

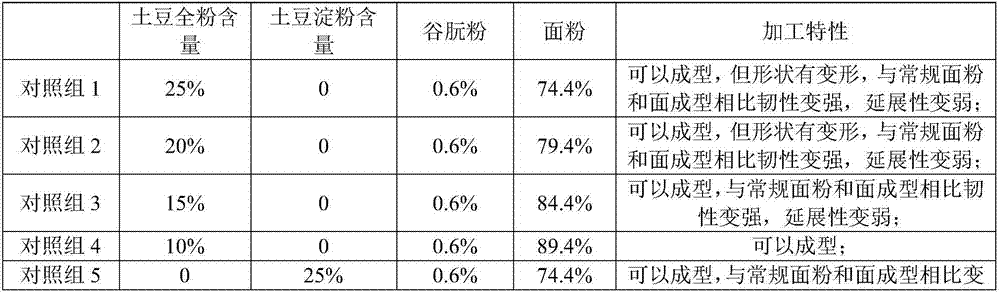

[0041] The content of potato extruded puffed powder, potato raw powder, gluten powder, rutin powder, and flour is mixed according to the ratio described in the following table 1, and the processing characteristics when making fried instant food. The experimental results of the control group of adding potato whole powder and adding potato starch in flour alone:

[0042] Table 1

[0043]

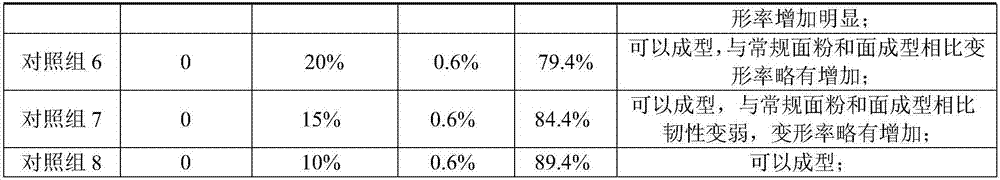

[0044] Table 2

[0045]

[0046]

[0047] As can be seen from Table 2, adding 25% potato whole powder or 25% potato starch to flour alone will cause the original flour characteristics to be changed, and it cannot be processed according to the conventional fried instant food The equipment produced the original product, and the processing characteristics also deteriorated when making fried convenience foods. When 15% whole potato flour is added to the flour, it can be molded. Compared with conventional flour and dough molding, the toughness becomes stronger and the ductility becomes w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com