Lens barrels

A lens barrel and lens technology, applied in installation, shutter, optics, etc., can solve the problems that hinder the thinning and miniaturization of the lens barrel, and achieve the effect of preventing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

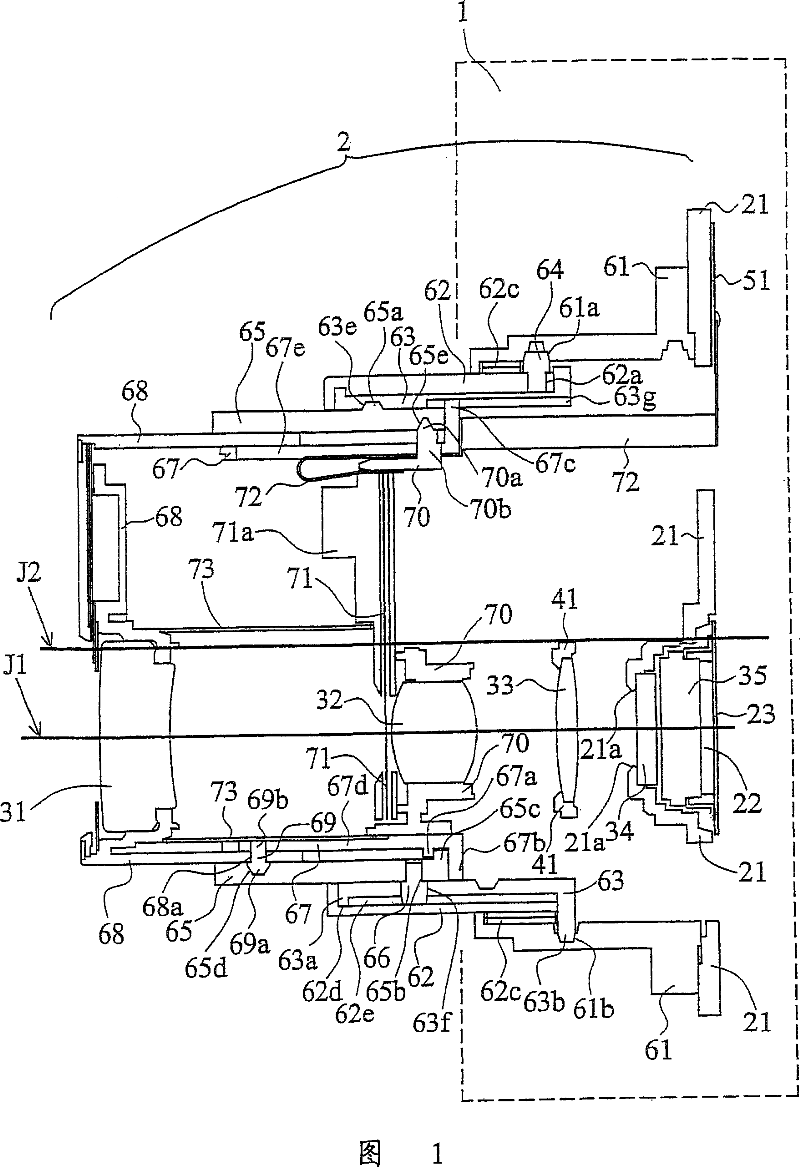

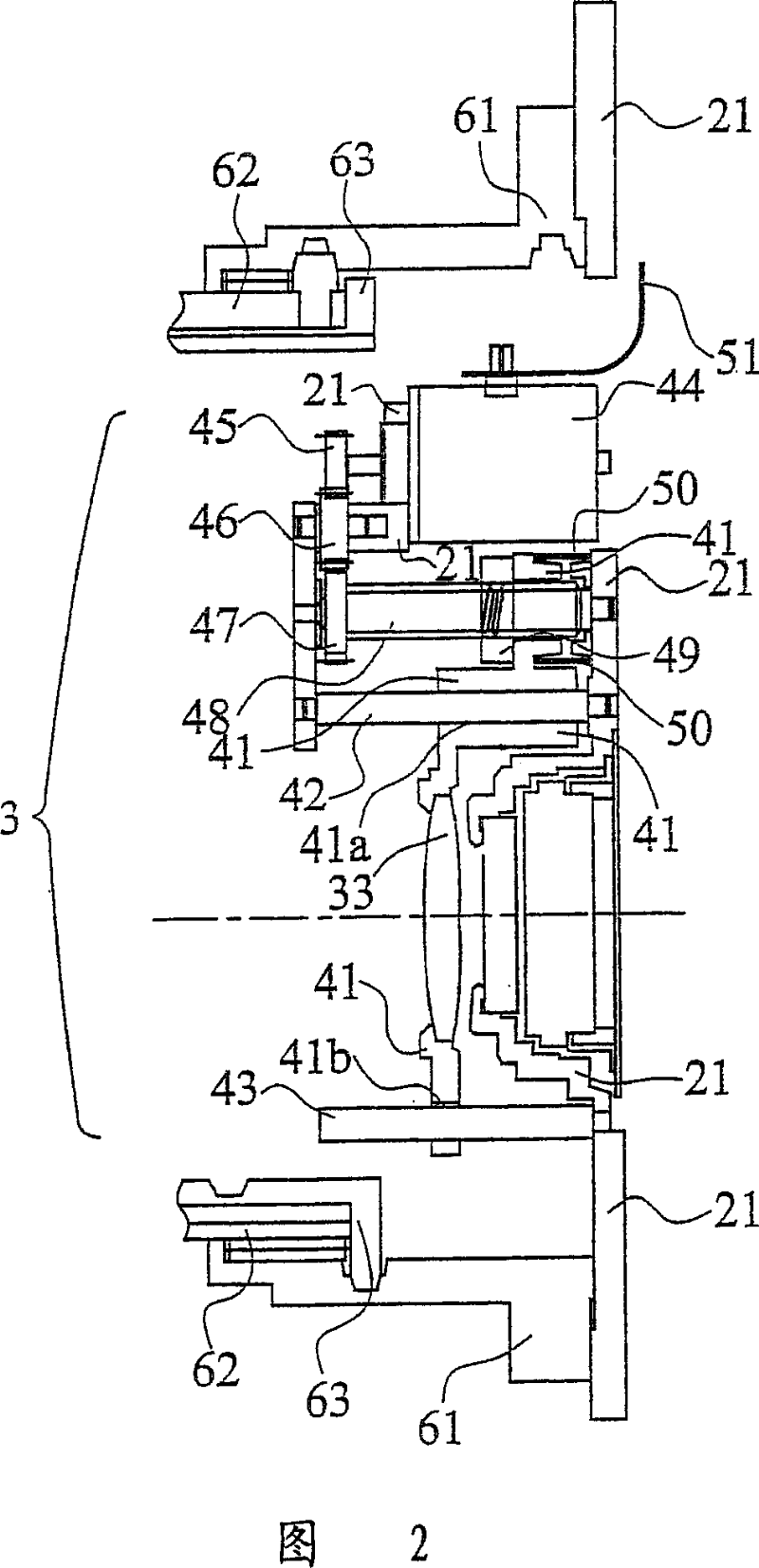

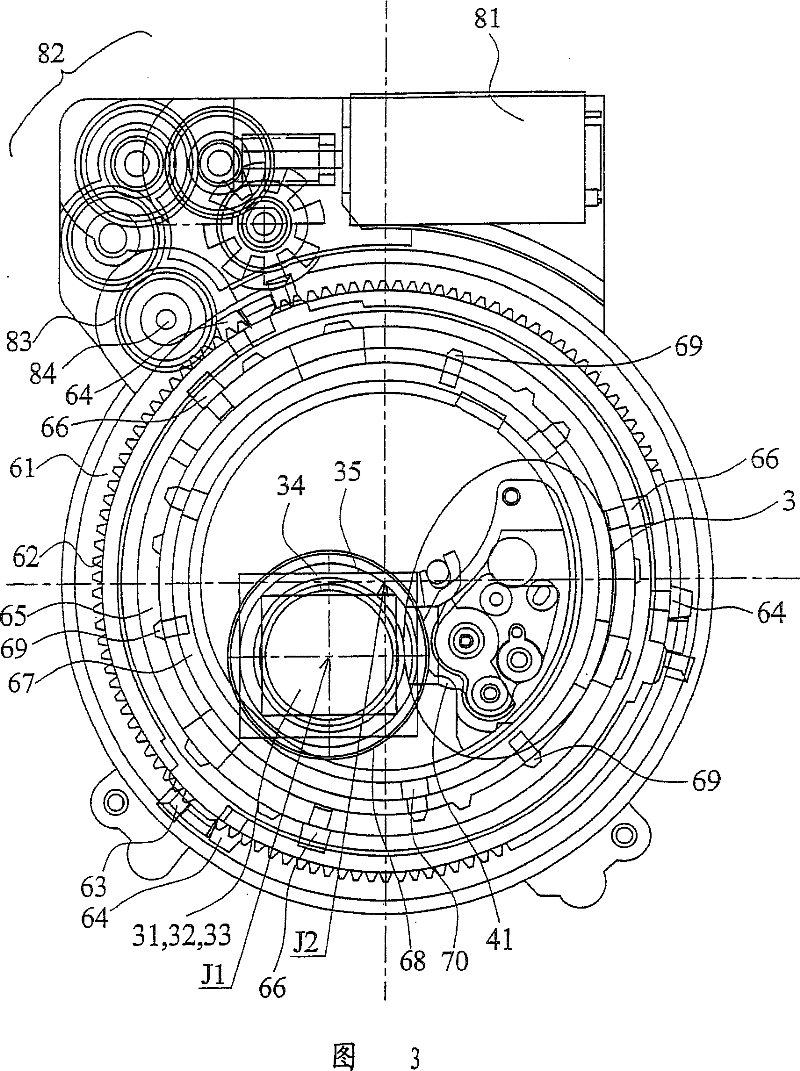

[0042] 1 to 29 illustrate the overall configuration of the lens barrel of this embodiment. In this embodiment, the present invention is applied to a zoom lens barrel for a digital camera.

[0043] FIG. 1 is a cross-sectional view showing the lens barrel 2 in a shooting position on the wide-angle side. The photographing optical system is composed of a first lens group 31, a second lens group 32, a third lens group 33, a low pass filter (low pass filter) 34, and a CCD (photographic device) 35 in order from the subject side. . The optical axis of the photographic optical system is J1. The photographic optical axis J1 is parallel to the central axis J2 of the lens barrel, and is eccentric to the central axis J2. Zooming is performed by moving the first lens group 31 and the second lens group 32 in the direction of the imaging optical axis J1, and focusing is performed by moving the third lens group 33 in the direction of the imaging optical axis J1. Light beams passing through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com