Pressure reducing valve and method thereof

A pressure reducing valve and disc technology, applied in the field of pressure reducing valves, can solve problems such as increased manufacturing costs, inability to respond to fluid pressure, complex design of pressure reducing valves, etc., to achieve stable guidance, increased life, and reduced axial rotational force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0105] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

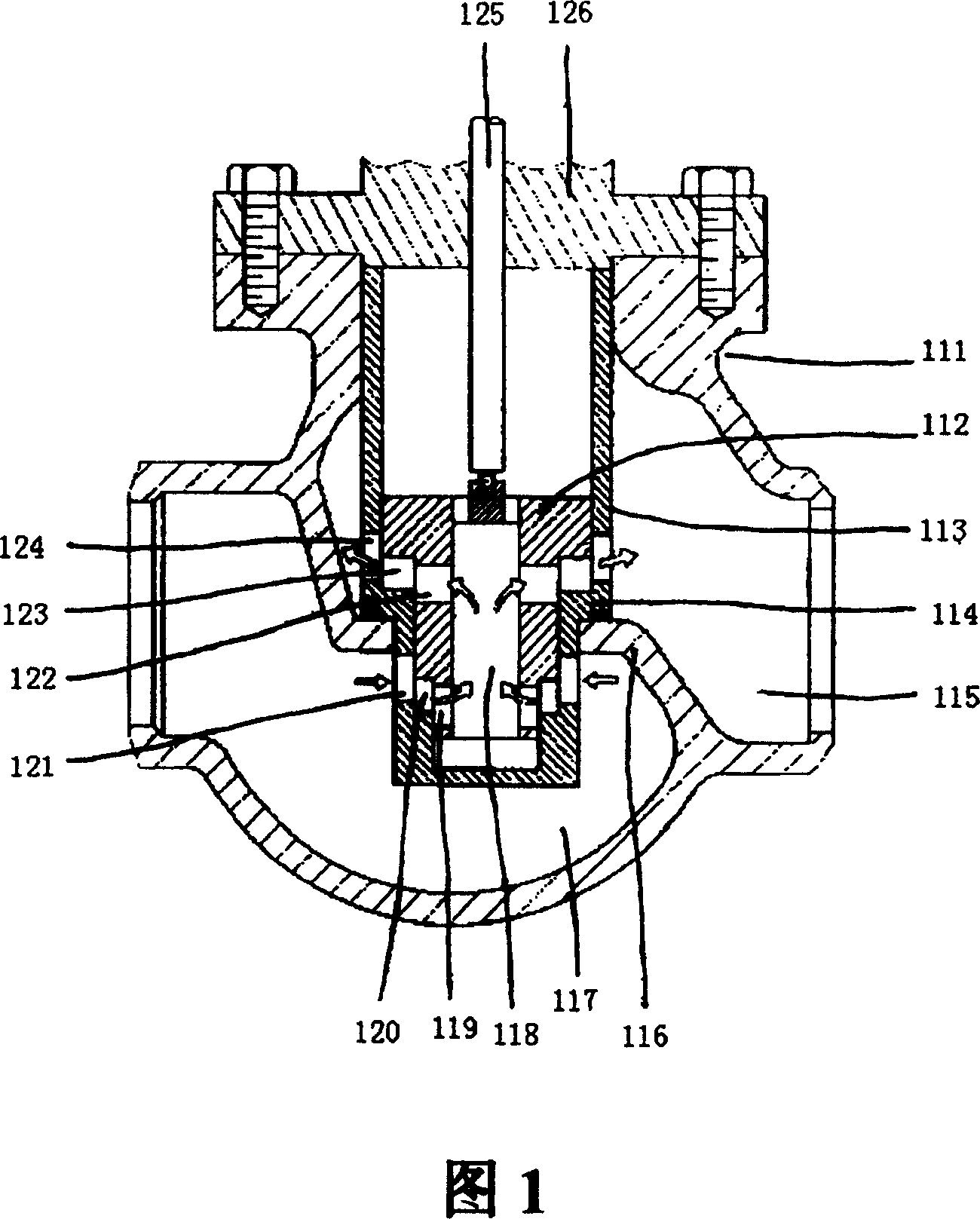

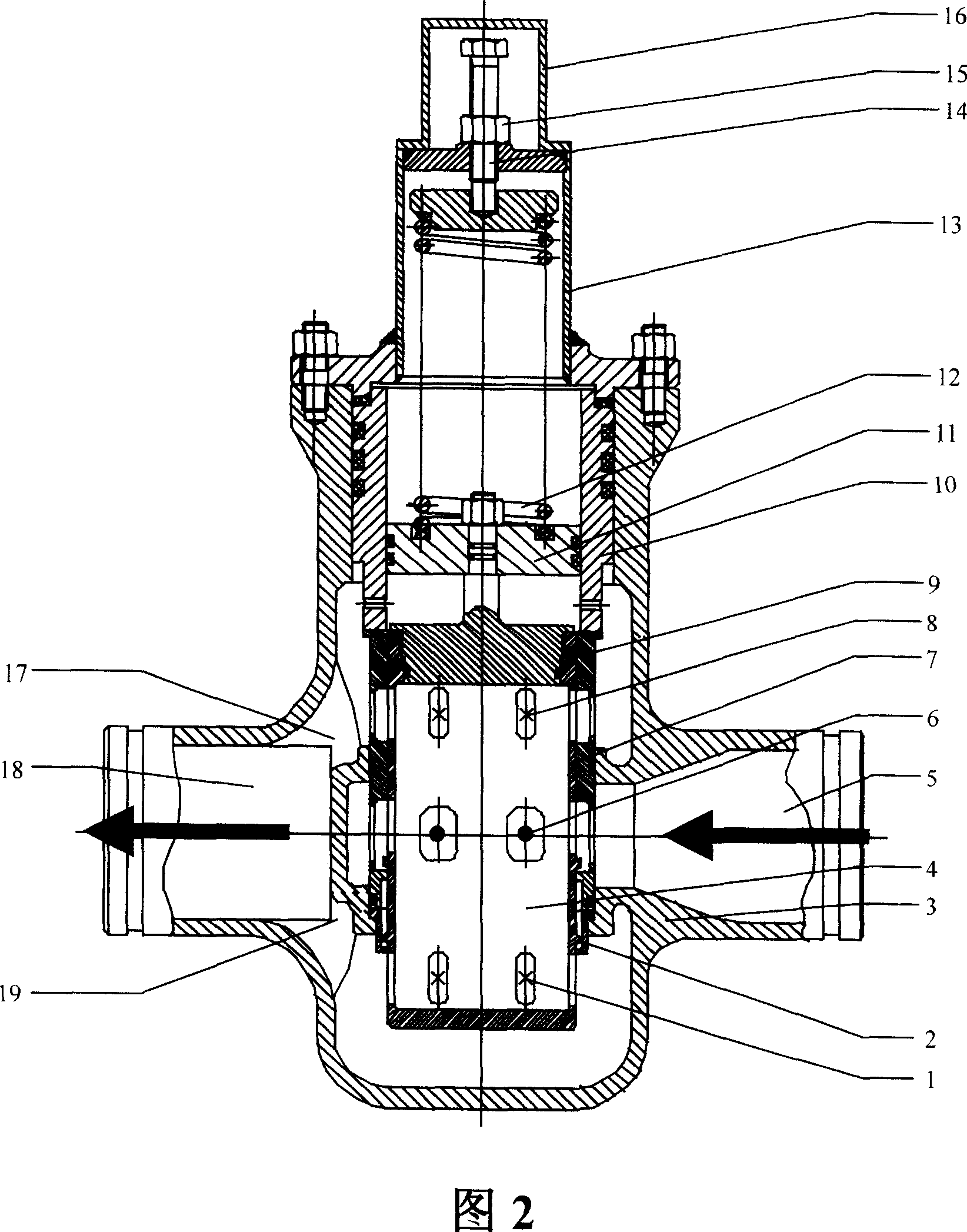

[0106] Fig. 2 is a schematic diagram showing the structure of a pressure reducing valve according to a specific embodiment of the present invention.

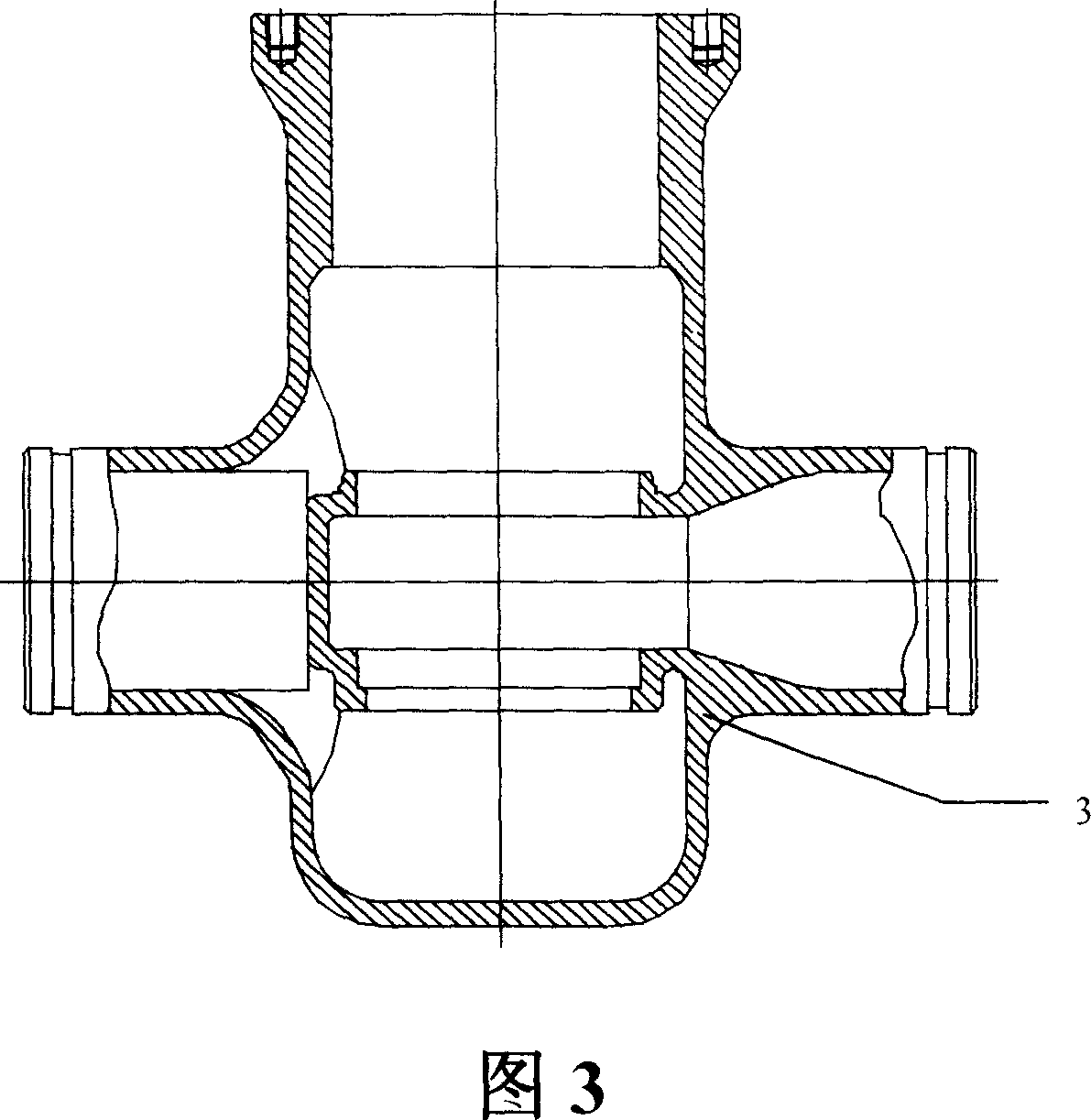

[0107] As shown in FIG. 2 , the pressure reducing valve according to the present invention mainly includes a valve body 3 , a valve core 4 and the like. The valve body 3 and the valve core 4 jointly define a fluid channel with two stages of throttling, and the channel connects the inlet 5 and the outlet 18 .

[0108] In practical applications, both ends of the valve body 3 of the pressure reducing valve are connected (eg, welded) to the fluid inlet and outlet joints of pipelines or equipment, wherein the inlet 5 of the valve body 3 is connected to a fluid pressure source (not shown). The machining dimensions above the mating surface of the valve seat 2 in the vertical direction of the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com