Forming machine for full steel wire meridian engineering tyre

An engineering tire and radial technology, which is applied in the field of all-steel radial engineering tire building machines, can solve the problems of slow progress of all-steel radial engineering tire projects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

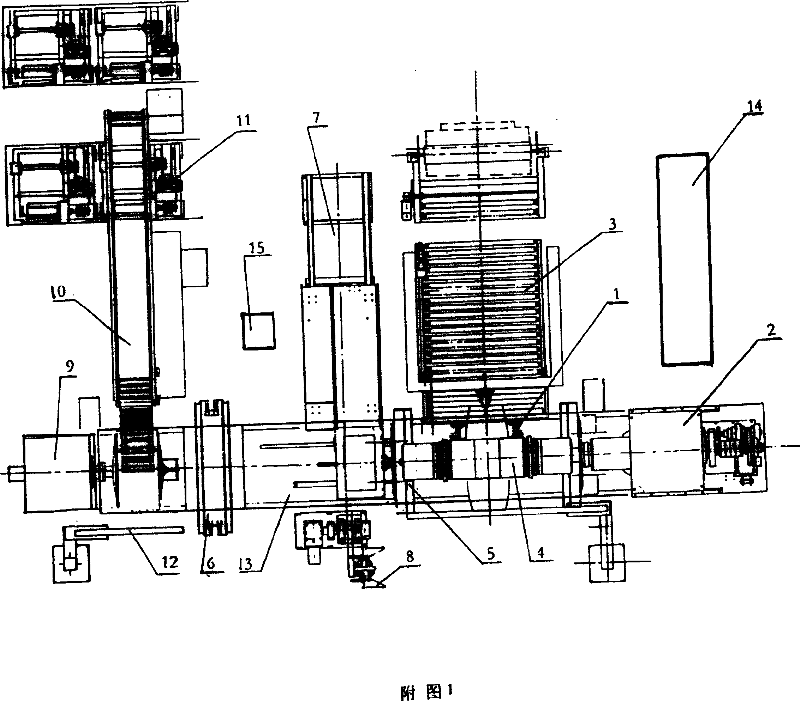

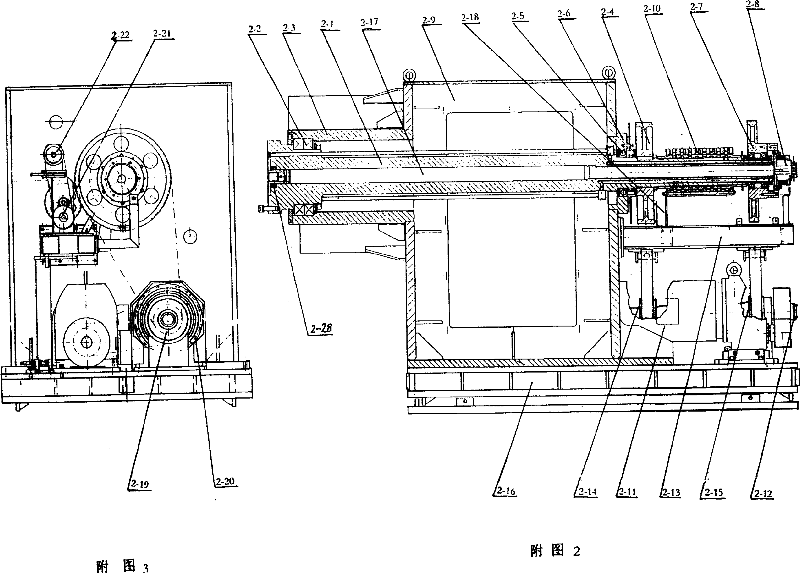

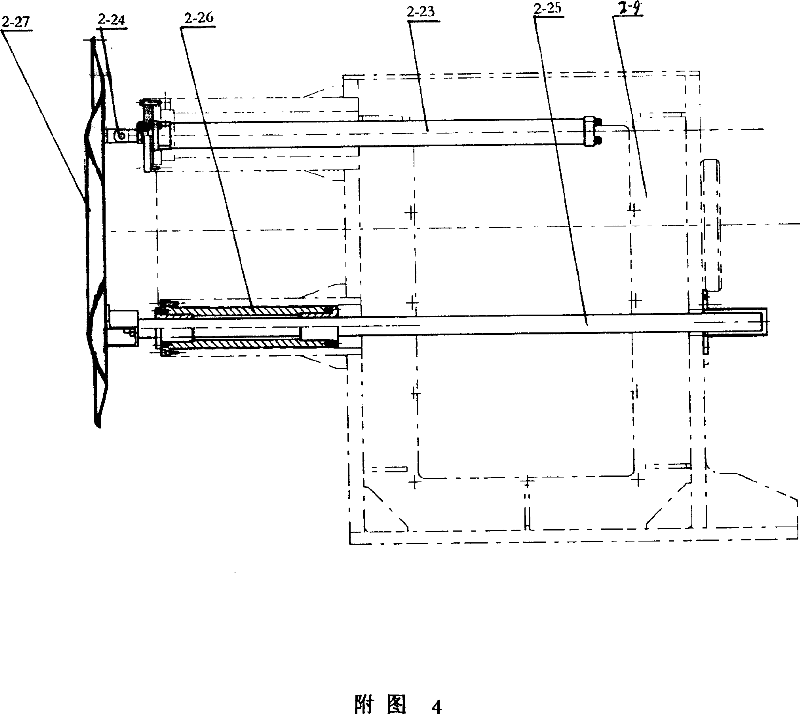

[0029] Embodiment: All-steel radial engineering tire building machine (see Figure 1), including the main feeding frame mechanism 3, the mobile car feeding mechanism 11, the belt crown feeding frame mechanism 10, the rear pressure roller mechanism 1, and the base rail mechanism 13. Carcass transfer cover mechanism 5, belt transfer ring mechanism 6, cursor positioning mechanism 12, electric control system 14 and hydraulic station system 15, characterized in that the main drive box of the shaping drum is installed between the two ends of the base rail mechanism 13 in sequence Mechanism 2, capsule shaping drum mechanism 4, tailstock mechanism 7, bead preset frame mechanism 8 and belt drum main transmission box mechanism 9, the input end of said rear pressure roller mechanism 1 is a three-dimensional transmission device, and the output end is Pressing wheel group; the input end of the main drive box mechanism 2 of the shaping drum is the main motor 2-11, and the output end is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com