Foldable container

A container and packing cloth technology, which is applied in the field of containers, can solve the problems of limited number of recycling, waste of packaging materials, cement, fly ash and grain in bulk, which are difficult to popularize and apply, and achieve the effect of smooth appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

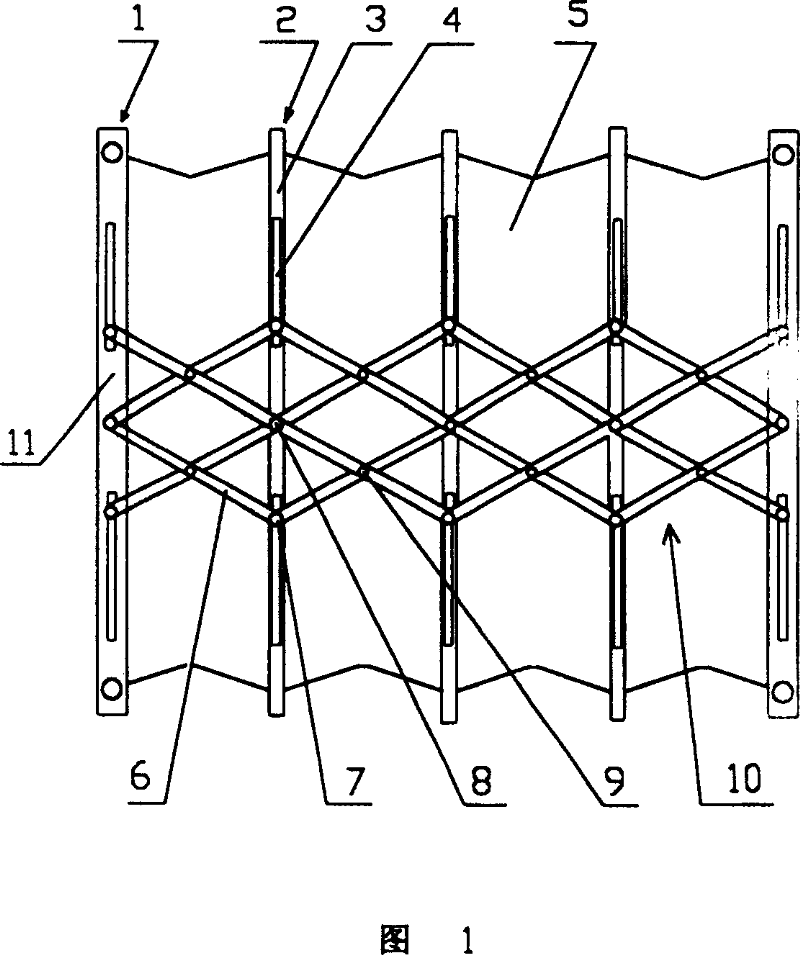

[0016] A folding container, which includes an end frame 1, an inner frame 2, a scissor bracket 10, and a high-strength flexible packaging cloth 5 (the high-strength flexible packaging cloth 5 adopts high-strength polyester industrial filament woven cloth, and the surface is PVC-coated). Three inner frames 2 are arranged between the two end frames 1, and the inner frame 2 and the two end frames 1 are connected with each other by a scissor bracket 10, and when the scissor bracket 10 stretches, it drives the inner frame 2 and the end frame 1 to move synchronously And complete the overall expansion and contraction, the high-strength flexible packaging cloth 5 is connected with the inner frame 2 and the end frame 1 to form a retractable closed box, and the end of the box is provided with loading and unloading doors (or valves).

[0017] The scissor bracket 10 of embodiment 1 is arranged on the outside of the side columns of the frames 1 and 2, and the high-strength flexible packing ...

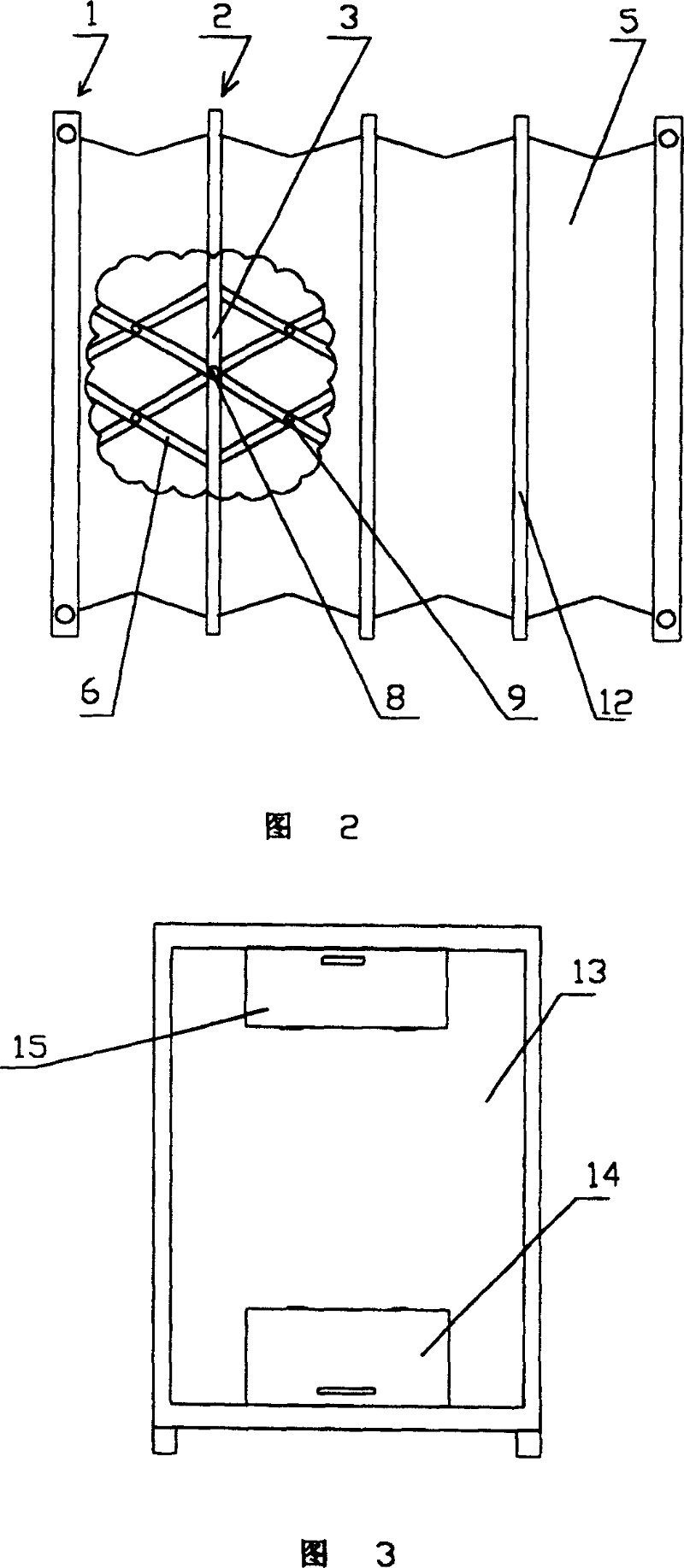

Embodiment 2

[0023] The structure of embodiment 2 is basically the same as that of embodiment 1, the difference is that the scissor brackets are arranged on the inside of the side columns of frames 1, 2, and the high-strength flexible packaging cloth 5 is wrapped on the periphery of frames 1, 2, and the protective The board 12 is fixed and pressed against the frame to form four sections of flexible packaging boxes, which communicate with each other through the frames 1 and 2 . The ends of the two end frames are covered with steel plates 13 (or other materials), and there are discharge doors 14 and loading doors 15 (or valves). The four sections of flexible packaging boxes together form a sealed box. When the volume needs to change, the flexible packaging cloth provides space for the volume change of the container by folding.

[0024] In the packaging operation, during the process of loading materials into the container, the container can maximize its volume by itself through the extrusion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com