Dust collecting unit in suction cleaner

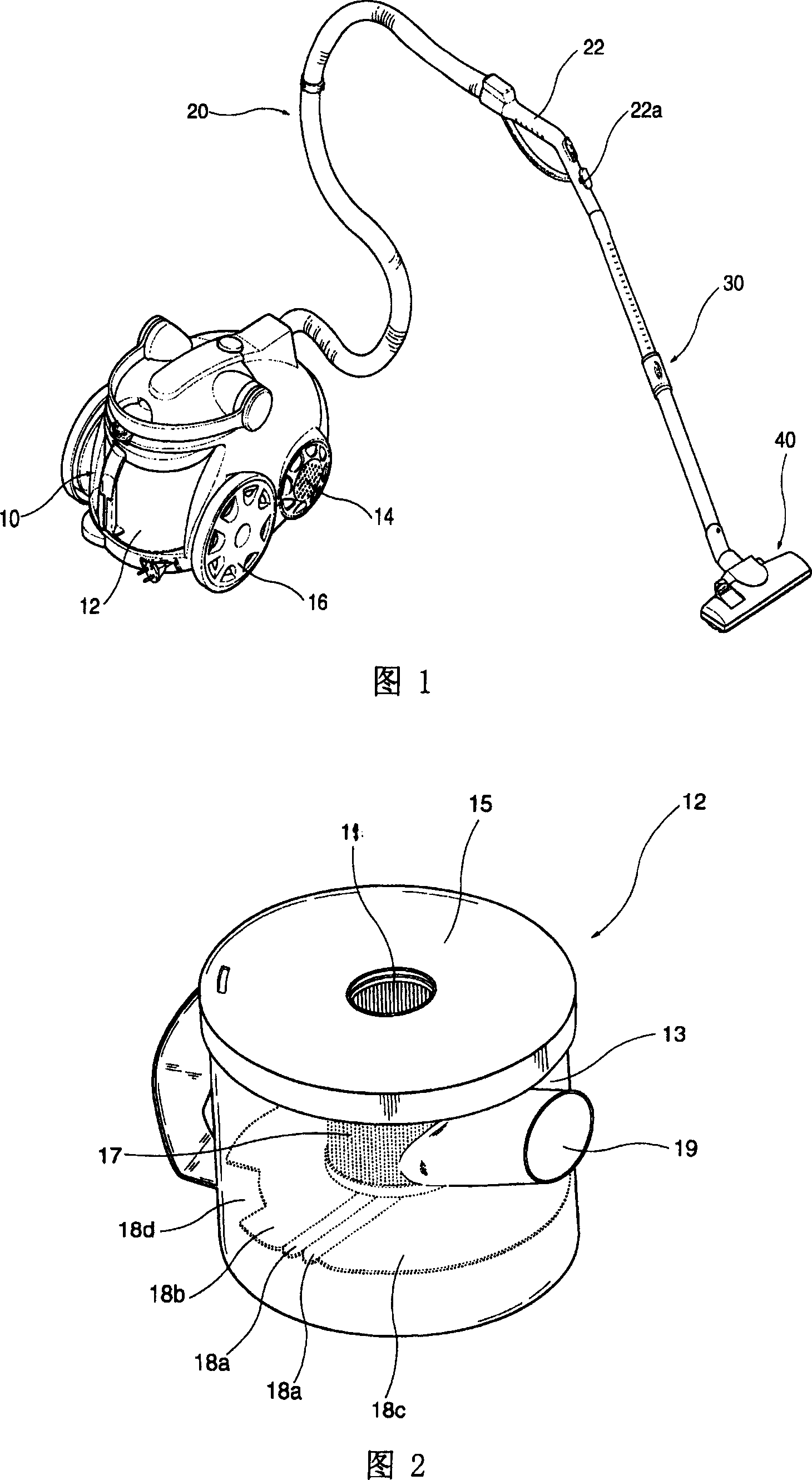

A technology for vacuum cleaners and dust collection chambers, which is applied in the field of vacuum cleaners, can solve the problems of polluted dust collection chambers, doubts about the performance of cyclone-type vacuum cleaners, insufficient cleaning power of the vacuum cleaners, etc., and achieves the effect of increasing the maximum ash storage capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

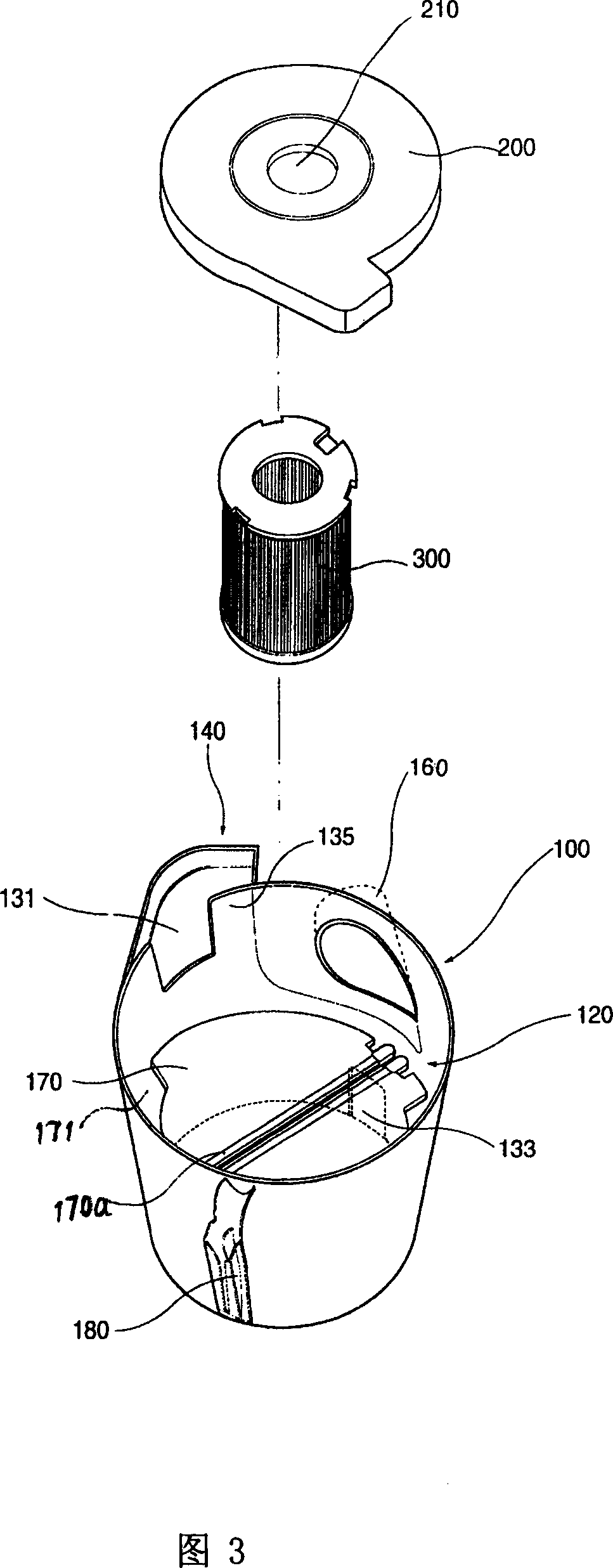

[0033] The present invention will be further described in detail below with reference to the drawings and specific embodiments: Fig. 3 is an exploded schematic diagram of the dust collection unit provided by the present invention. As shown in Fig. 3, the dust collection unit provided by the present invention includes a dust collection chamber 100 with an open upper part, a cover 200, and a filter element 300. The cover 200 is provided on the opening above the dust collection chamber 100 to open and close the dust collection chamber 100. The filter element 300 is arranged on the cover 200 to filter the air to be discharged.

[0034] The dust collection chamber is provided with an inflow port 160 through which foreign matter flows, and a main dust collection chamber 120, a secondary dust collection chamber 140 and other structures for storing foreign matter. In order to allow the air mixed with dust flowing into the dust collection chamber 100 to form a vortex along the inner side w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com