Pulverization system and method for biomass fuel production

A biomass fuel and crushing system technology, applied in grain processing, etc., can solve the problems of reducing the contact probability of materials and crushing cutter head, reducing the crushing efficiency, reducing the purity of products, etc., so as to avoid the formation of a large amount of slagging, improve the crushing efficiency, Avoid the effect of persistent accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present application is described in detail below in conjunction with the examples, but the present application is not limited to these examples.

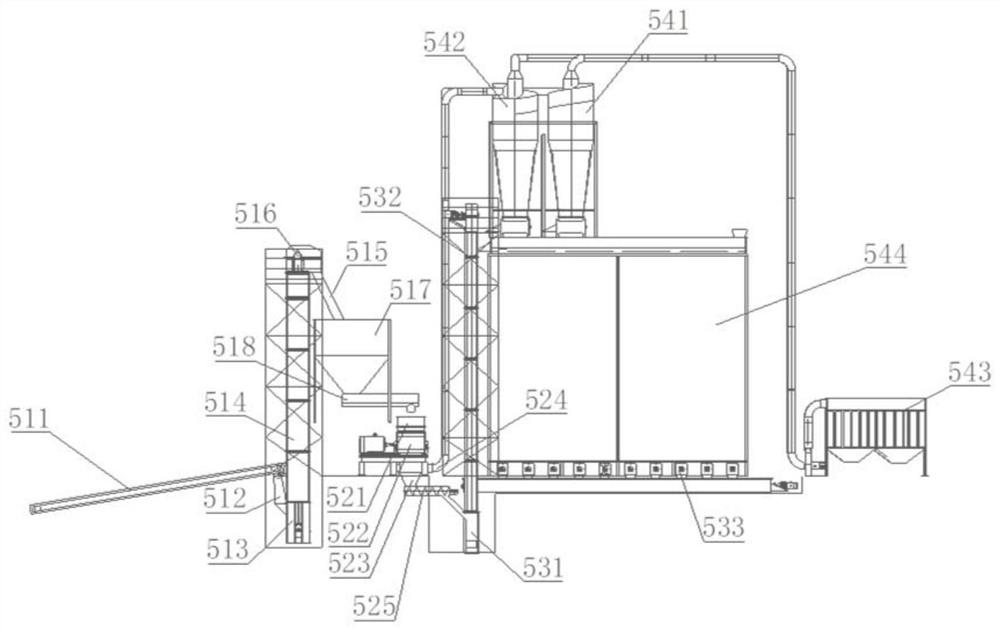

[0049] see figure 1 , The pulverization system and method for biomass fuel production provided by this application includes: a conveyor belt 511, a first material lifting mechanism, a storage bin 517, a pulverizer, a second material lifting mechanism, and a negative pressure dust removal system.

[0050] The conveyor belt 511 feeds the first material lifting mechanism. The conveyor belt 511 is arranged on one side of the first material lifting mechanism, and is in communication with the first material lifting hopper 513 in the first material lifting mechanism.

[0051] The first lifting mechanism includes: a first lifting frame 514, a first lifting hopper 513, a first lifting motor 516, and the first lifting motor 516 is installed on the top of the first lifting frame 514, and is driven and connected with the first lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com