Method and mechanism for delermining thickness and gripped feeding layer of carding machine

A thickness detection, carding machine technology, applied in the direction of measuring device, fiber processing, fiber feeding, etc., can solve the problems of carding effect variation, maintenance difficulties, poor carding, etc., to achieve uniform pressure and grip, accurate sampling and detection , adjust the effect of the control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

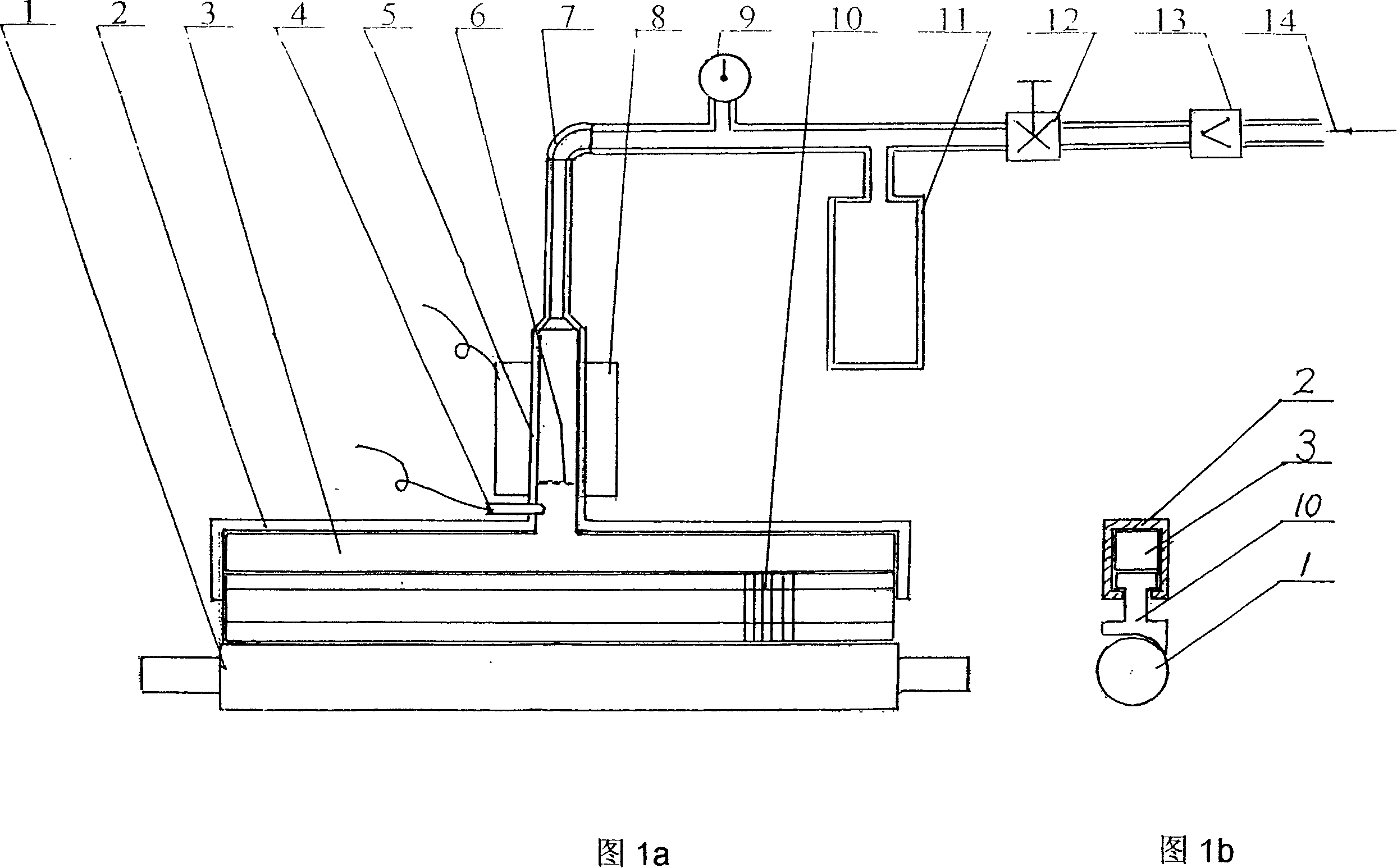

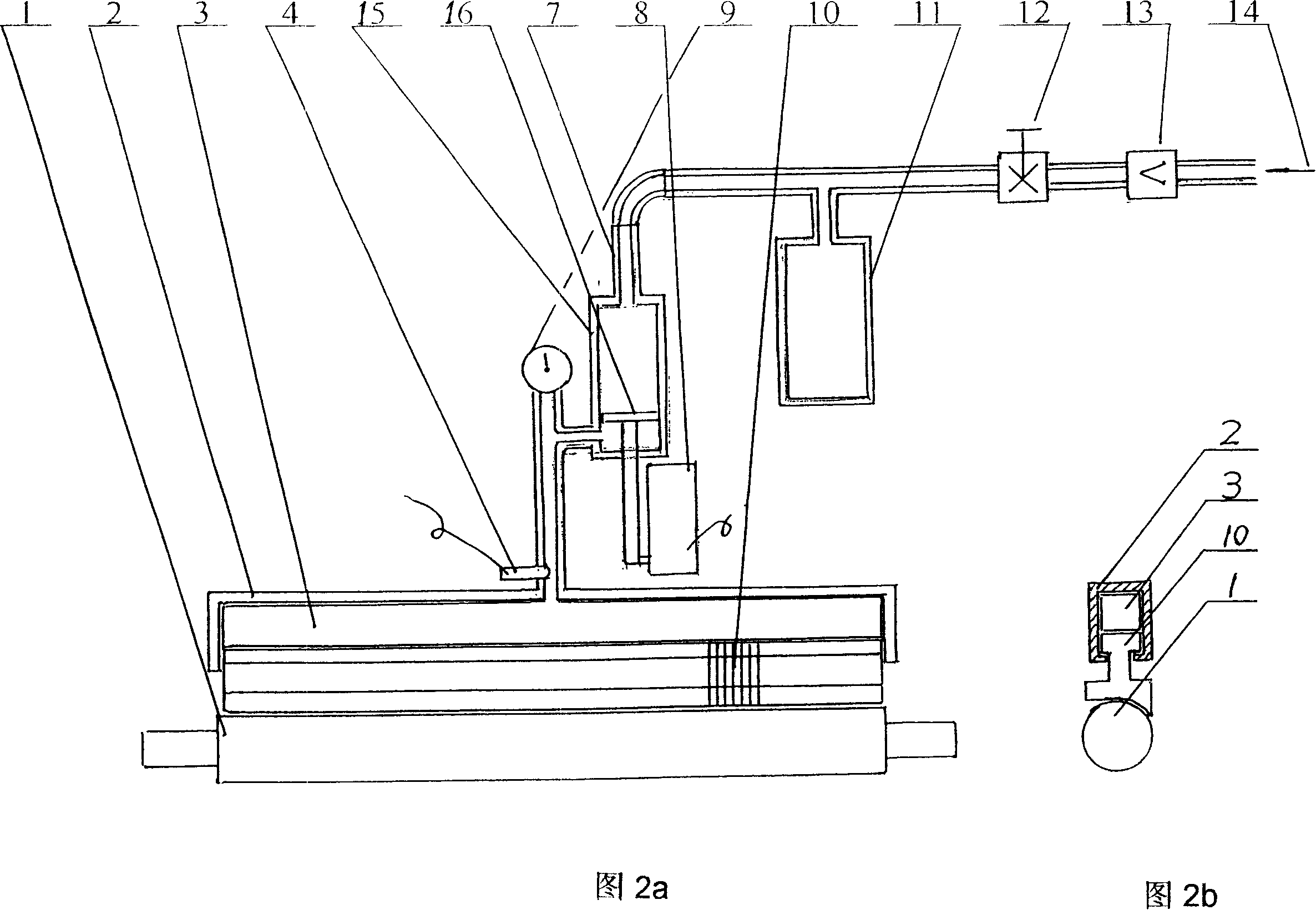

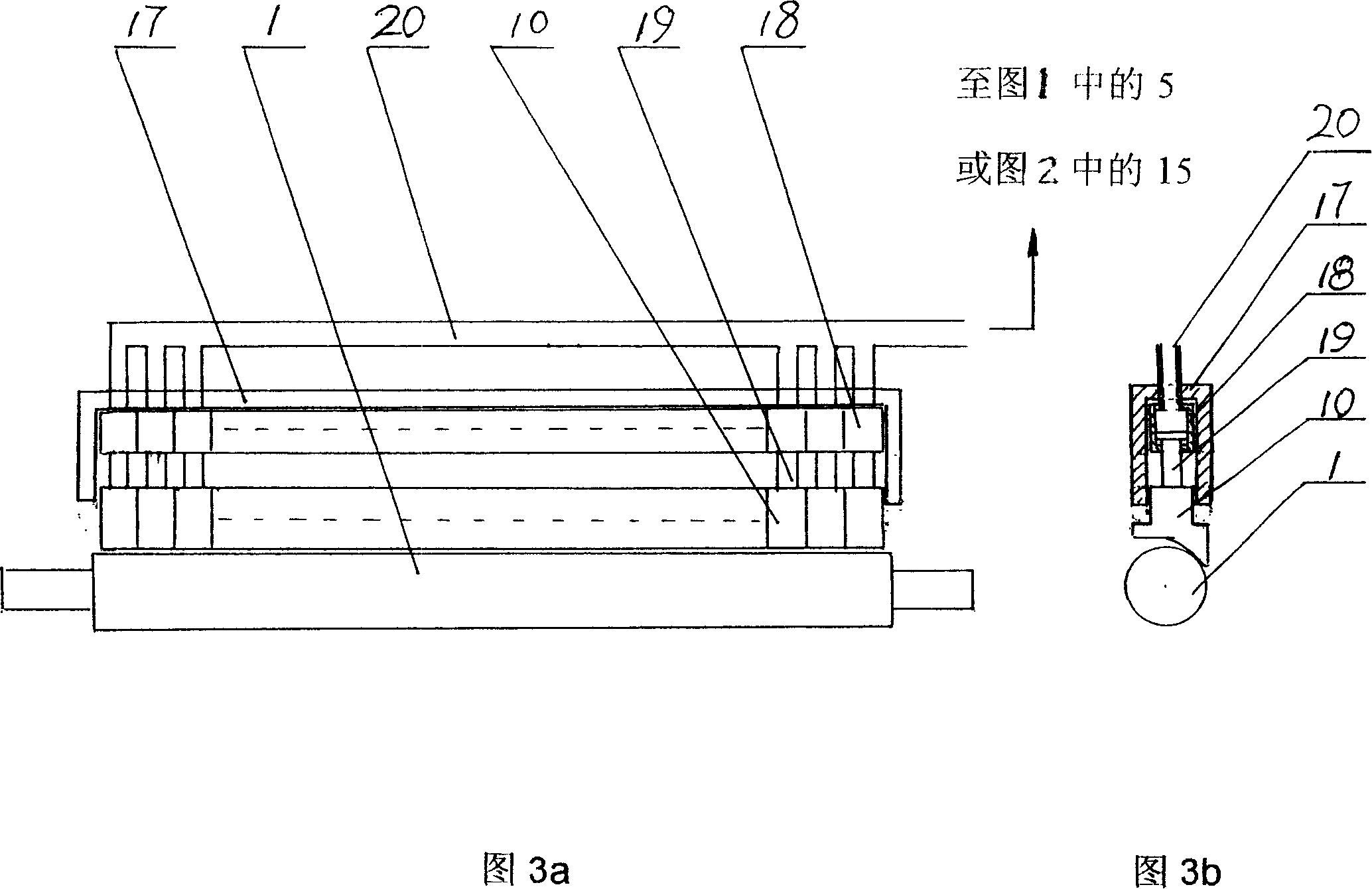

[0018] In conjunction with the accompanying drawings, the 50-section feeding layer holding and thickness detection mechanism for the feeding roller of the carding machine with a transverse width of 1000 mm is described as follows:

[0019] There are 50 segments within a transverse width of 1000 mm, and the width of each segment is 20 mm. Compared with the 10-segment sampling detection and pressurization holding mechanism in the prior art, the width subdivision degree is improved by 5 times.

[0020] In Fig. 1 and Fig. 2, a pressurized grip chamber 2 is arranged parallel to the cotton feed roller 1 above the cotton roller 1, and the pressurized grip chamber 2 is a firm cavity with an opening downward, and the cross-sectional dimension in the chamber is It is 20 millimeters high and 20 millimeters wide, and a soft capsule 3 made of elastic material of a corresponding size is placed in the cavity. Press block 10, press block 10 can have the stroke of 15 millimeters to move up an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com