Housing for tubine blade and assembling method thereof

A cover and blade technology, applied in the direction of blade support elements, machines/engines, mechanical equipment, etc., can solve problems such as expensive, labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

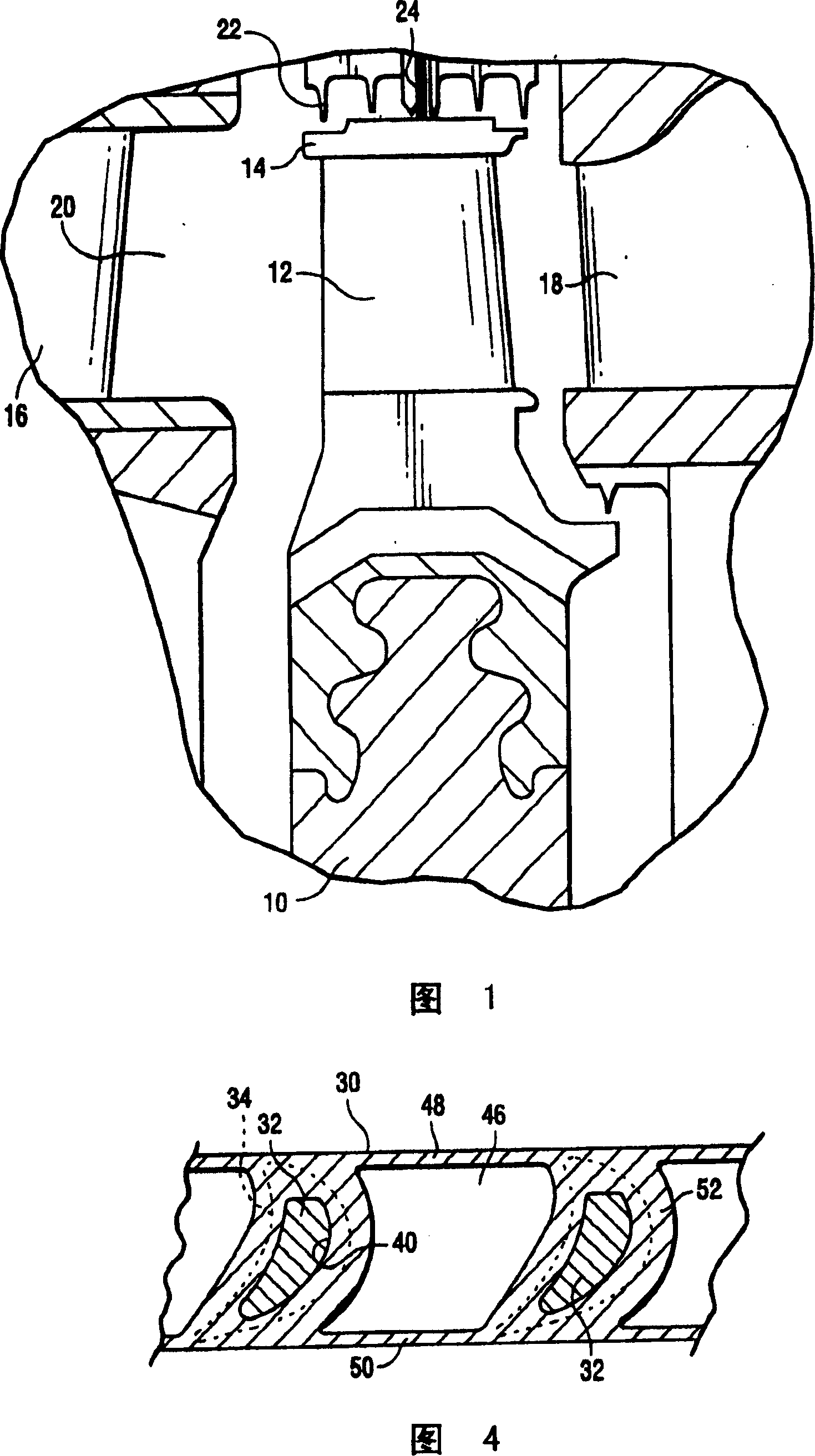

[0015] Referring now to the drawings, and in particular to FIG. 1 , there is shown mounted a plurality of circumferentially spaced blades, one of which is indicated at 12 and has a blade shroud 14 . The axially adjacent stator blades 16 and 18 of the stationary member of the turbine are also revealed in the turbine flow path 20 . A labyrinth seal 22 and a brush seal 24 are shown for sealing around the shroud 14 during operation of the turbine.

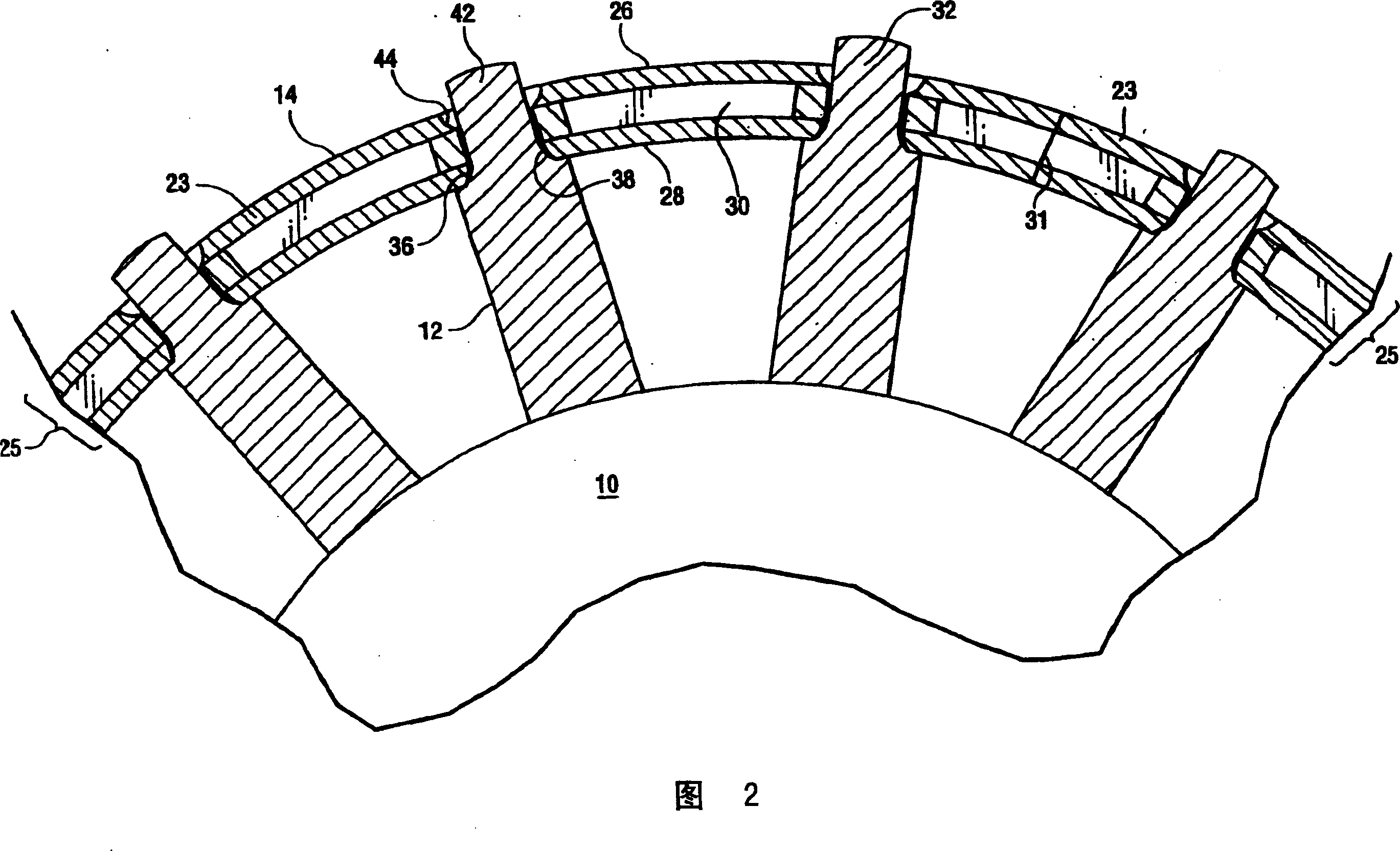

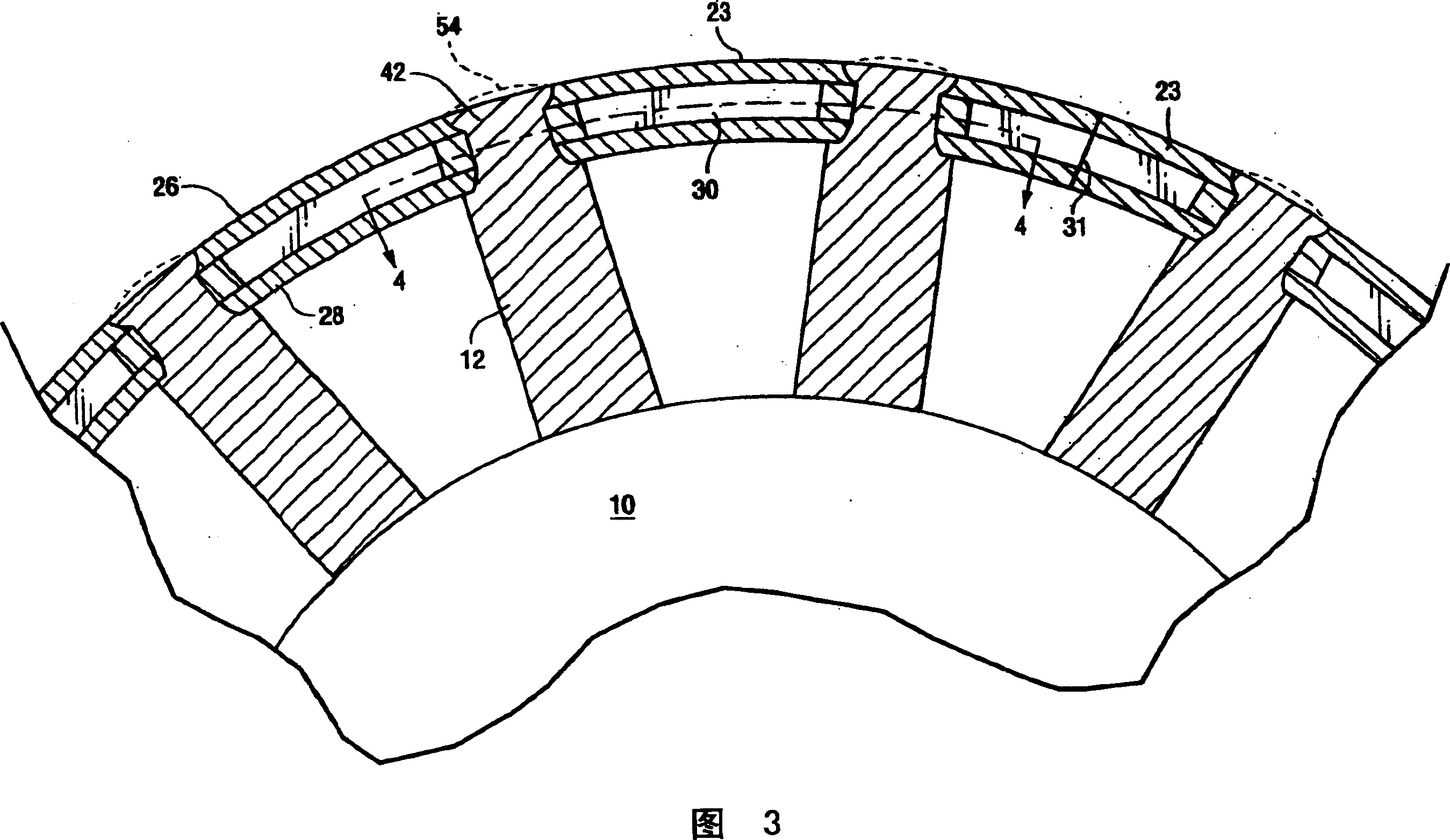

[0016] Referring now to FIG. 2 , the cover 14 includes a plurality of arcuate cover sections 23 each comprising a cover layer or element, generally indicated at 25 . As shown, the overall cover element 25 of each segment 23 includes an arcuately extending outer element 26 , an inner element 28 and an intermediate cover element 30 . The shroud elements 26, 28 and 30 extend in an arcuate manner across a plurality of blades 12, for example 4-20 blades, depending on the stage. These arcuate shroud sections are secured to tenons 32 formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com