Hot rolled reinforcing steel bar having ribs and deflecting roller

A technology of guide roller and steel bar, applied in the field of hot-rolled ribbed steel bar straightening method and guide roller field, can solve the problems of inability to clamp steel bar, transverse rib damage, and longitudinal rib distortion of steel bar.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

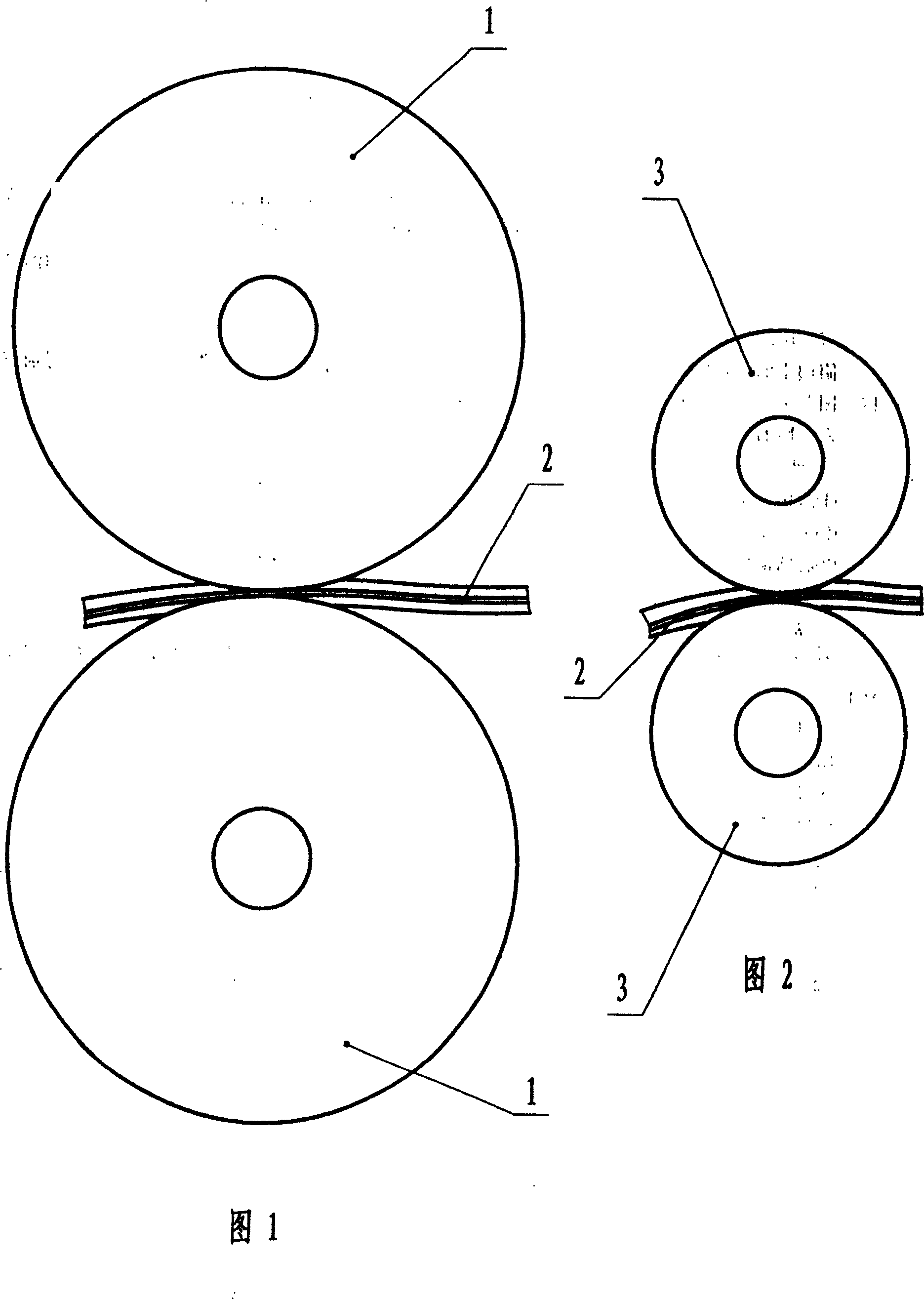

[0029] Embodiment one: when straightening the hot-rolled ribbed steel bar of Ф 10 millimeters, the external diameter of guide roller 1 of the present invention is 200 millimeters, and its external diameter is 20 times (as shown in accompanying drawing 1) of straightened steel bar diameter, Twice (as shown in Figure 2 ) larger than the outer diameter of existing guide roller 3, and the outer diameter of existing guide roller 3 is Ф100 millimeter, and its outer diameter is only 10 times of the steel bar diameter being straightened.

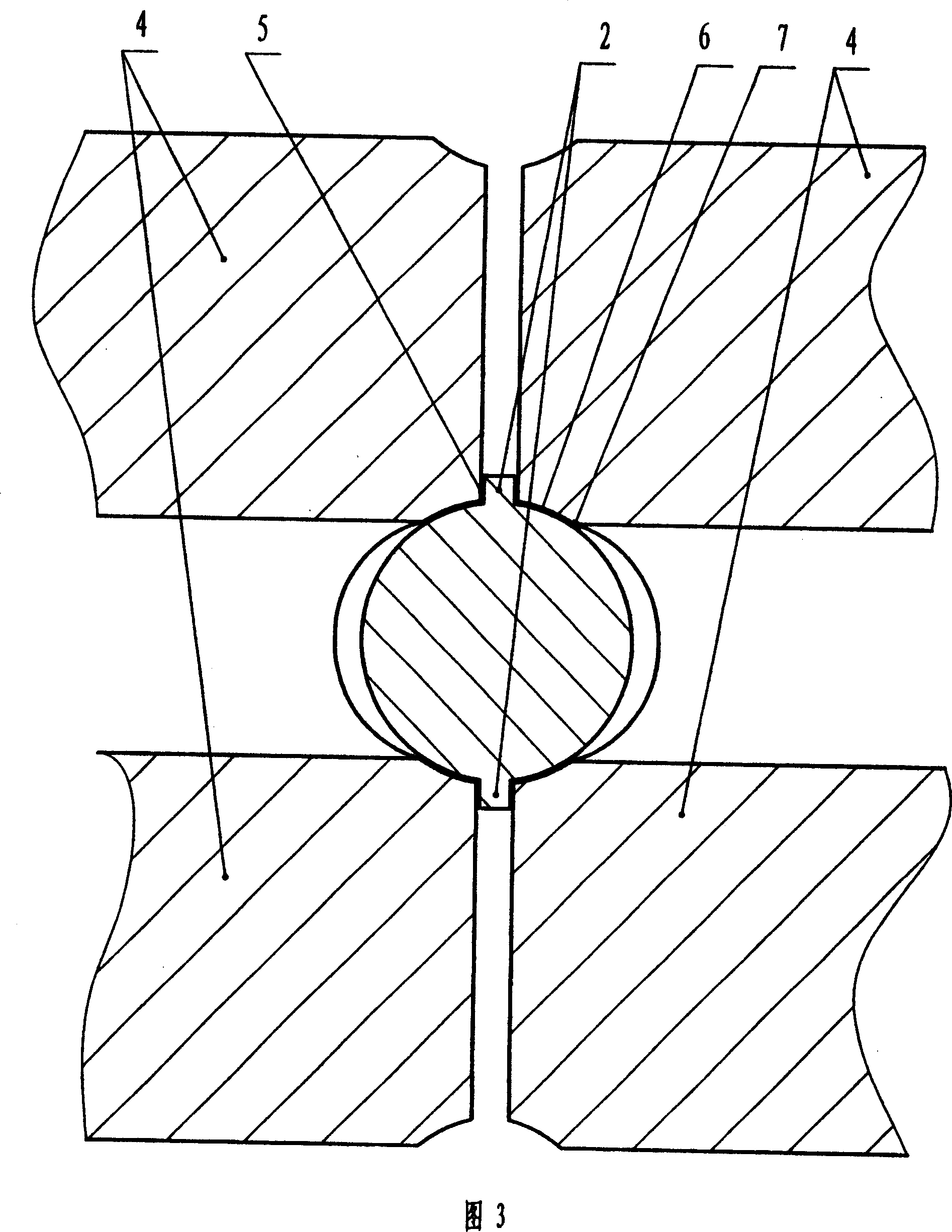

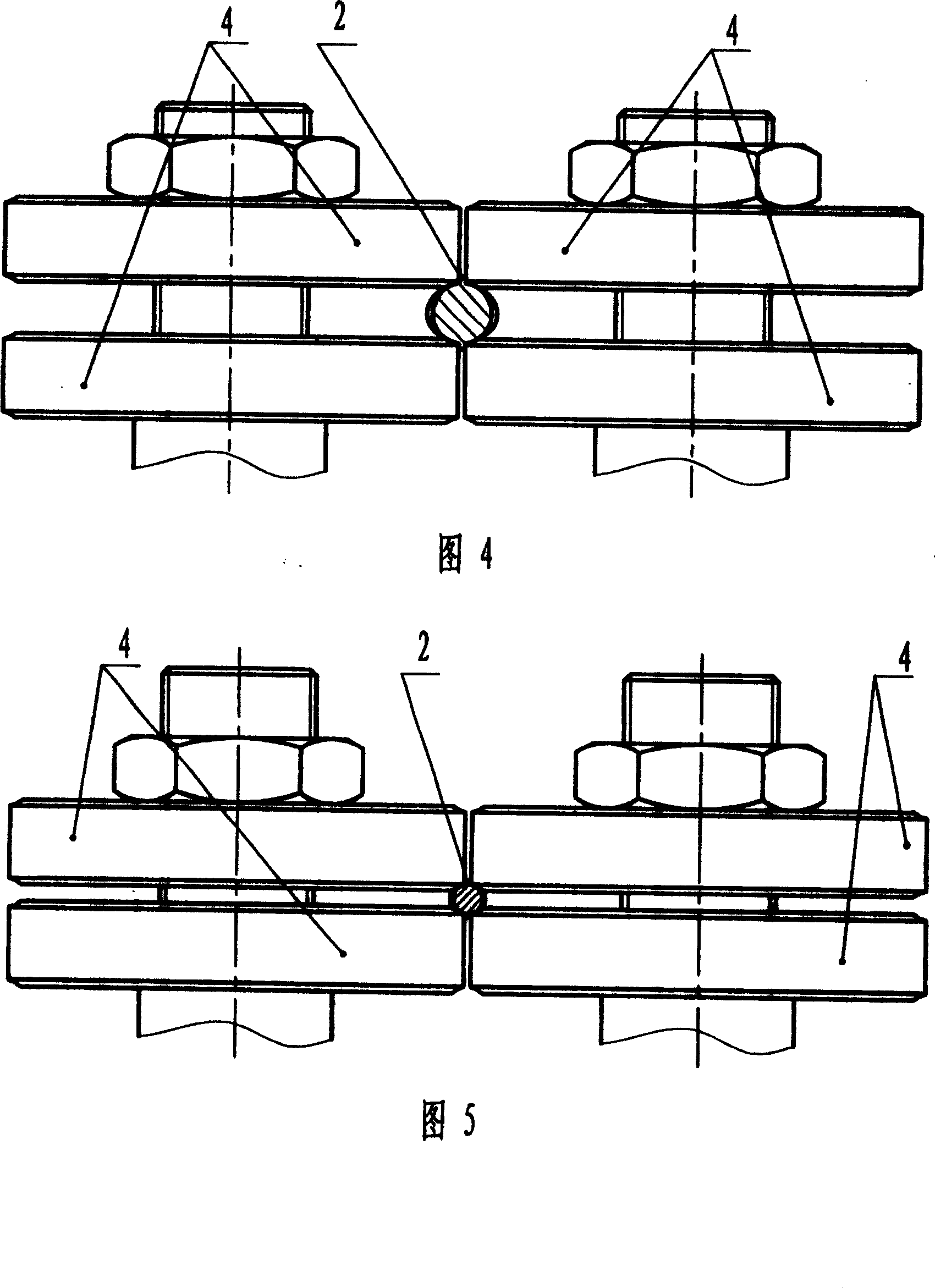

[0030] When the continuously advancing hot-rolled ribbed steel bar longitudinal rib 2 entered a pair of guide rolls 1 of the present invention that were constantly rotating, since the outer diameter of the guide roll 1 of the present invention was significantly larger than the existing guide roll 3, their contact with the steel bar longitudinal rib 2 Situation also has significant difference, the working part of guide roller 1 of the present inventio...

Embodiment 2

[0034] Embodiment 2: When straightening the hot-rolled ribbed steel bars of Ф6-14 mm, the outer diameter of the guide roller 1 of the present invention is designed to be 420 mm, that is: when straightening the hot-rolled ribbed steel bars of Ф6 mm, the guide roller 1 of the present invention is designed to be 420 mm. The outer diameter of the roller 1 is 70 times of the diameter of the steel bar to be straightened; when straightening the hot-rolled ribbed steel bar of Ф14 mm, the outer diameter of the guide roller 1 of the present invention is 30 times of the diameter of the steel bar to be straightened.

Embodiment 3

[0035] Embodiment 3: When straightening the hot-rolled ribbed steel bar of Ф6-14 mm, the outer diameter of the guide roller 1 of the present invention is designed to be 210 mm, that is: when straightening the hot-rolled ribbed steel bar of Ф6 mm, the guide roller 1 of the present invention is designed to be 210 mm. The outer diameter of the roller 1 is 35 times of the diameter of the steel bar to be straightened; when straightening the hot-rolled ribbed steel bar of Ф14 mm, the outer diameter of the guide roller 1 of the present invention is 15 times of the diameter of the steel bar to be straightened.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com