Method and apparatus to sort particles flowing from verticle grinder

一种颗粒、颗粒流的技术,应用在分离方法、弥散粒子分离、化学仪器和方法等方向,能够解决增加压力损失、减小分选效率等问题,达到避免干扰的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

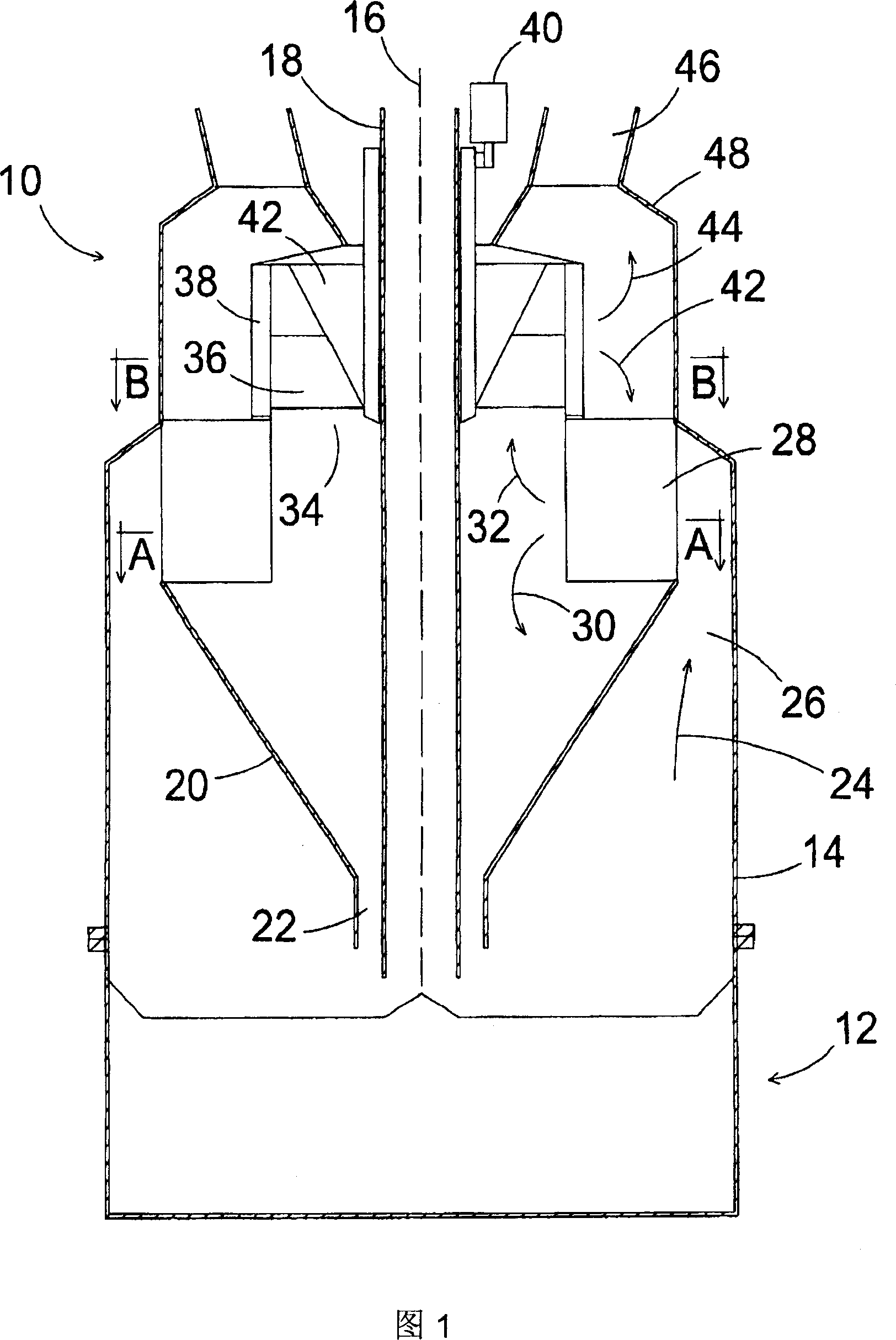

[0031] FIG. 1 schematically shows a classifier 10 connected to a vertical spindle mill 12 . Sorter 10 includes a generally cylindrical housing 14 having a vertical axis 16 . At the shaft 16 is often arranged a feed pipe 18 for guiding the raw material to the center of the mill 12 to be ground as it travels towards the outer edge of the mill 12 .

[0032] Inside the outer shell 14 is arranged a conical inner shell 20 which has a central outlet 22 at the bottom for the outflow of the separated coarse particles from the classifier 10 to the mill 12 for regrinding. The outlet 22 may include a hinge structure (not shown) to prevent gas from flowing upwardly into the inner housing 20 through the opening 22 .

[0033] An annular gas and particle flow 24 flows upwardly from the mill 12 through a channel 26 formed between the outer shell 14 and the inner shell 20 . The flow 24 is directed to the inner shell 20 through an inlet and outlet formed by an annulus 28 comprising an angular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com