Combined gas-liquid separator

A technology of gas-liquid separator and liquid separator, which is applied in the field of combined gas-liquid separator, can solve the problem of insufficient separation efficiency, achieve the effect of strengthening the gravity separation process and improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

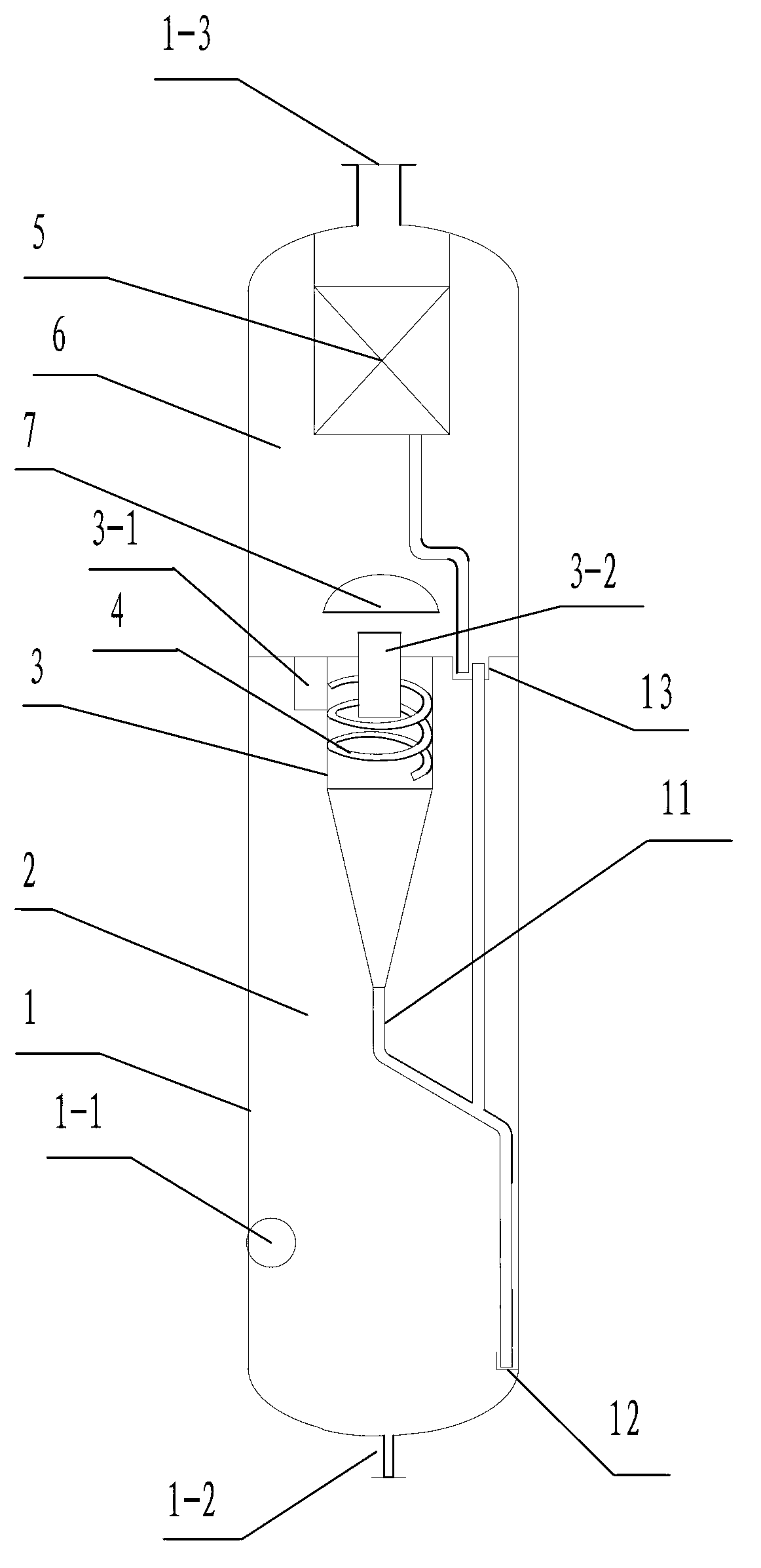

[0022] see figure 1 , which has a housing (1) with a gas phase outlet (1-3) at the top of the housing, a liquid phase outlet (1-2) and a gas-liquid mixed phase at the lower part of the housing Inlet (1-1); a cyclone gas-liquid separator is provided in the housing (1), and the cyclone gas-liquid separator consists of a cyclone separator (3) and a cyclone cylinder located in the cyclone separator The spiral vane deflector (4) inside the cyclone gas-liquid separator separates the upper chamber (6) and the lower chamber (2) of the shell cavity, and the air inlet of the cyclone gas-liquid separator (3- 1) It communicates with the lower chamber (2), and the air outlet (3-2) of the cyclone gas-liquid separator communicates with the upper chamber (6), and there is a collision at the air outlet (3-2) deflector baffle (7); a mist eliminator (5) is provided in the upper chamber (2), and the mist eliminator can be an ordinary wire mesh eliminator or a baffle plate eliminator, but It is...

Embodiment 2

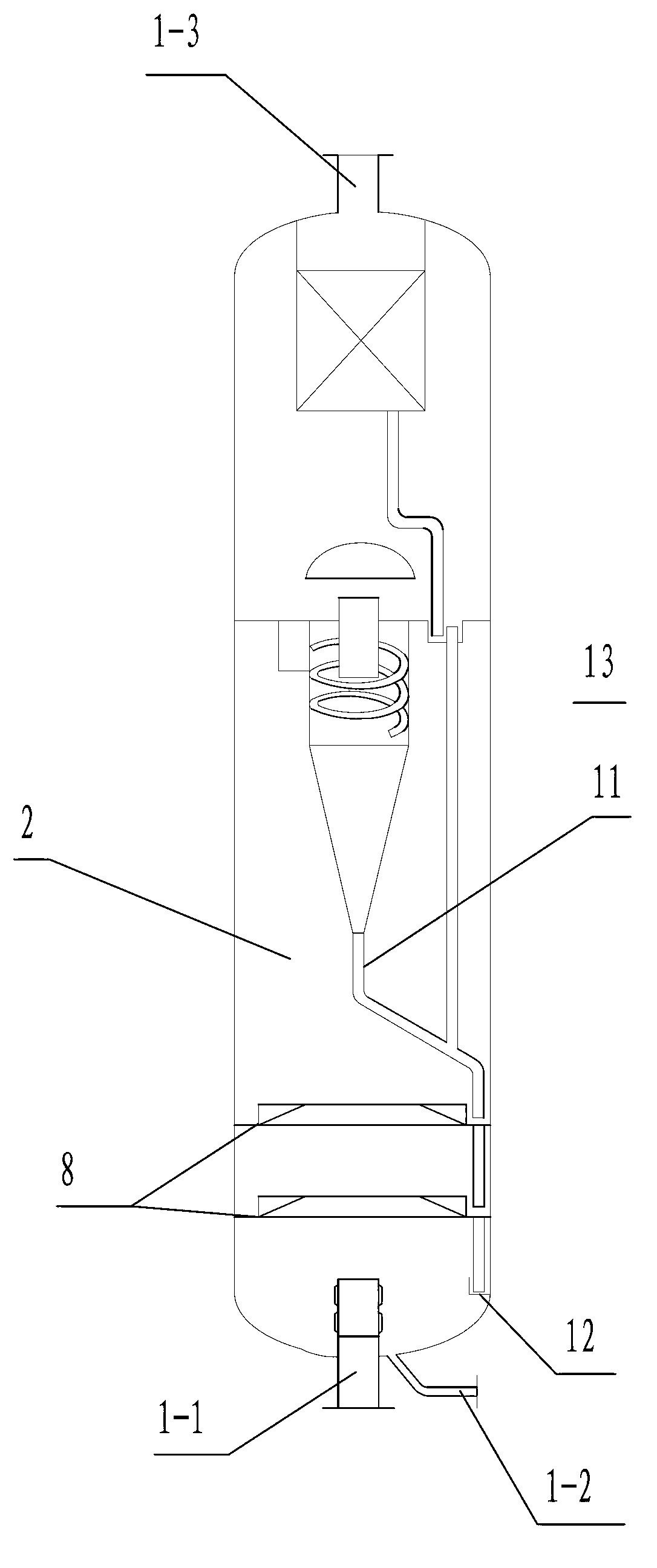

[0025] see figure 2 , the structure of this example is basically the same as that of Example 1, the difference is that a second-layer swirl plate (8) is added in the lower chamber (2), and the gas-liquid mixed phase inlet (1-1) adopts the lower Import, other structures are identical with embodiment 1. The intake air enters the shell (1) from the gas-liquid mixed phase inlet (1-1), passes through the double-layer swirl plate and is transformed into a rotating upward airflow, and the liquid droplets entrained in the airflow are thrown towards the inner wall of the shell at a certain elevation angle, and then Descends along the inner wall of the shell, enters the first liquid seal plate (12) through the guide tube, then overflows and descends to the bottom of the shell, and is discharged from the liquid phase outlet (1-2); the rotating and rising air flow enters the cyclone gas-liquid Separator, following process is identical with embodiment 1. In this example, another cyclone...

Embodiment 3

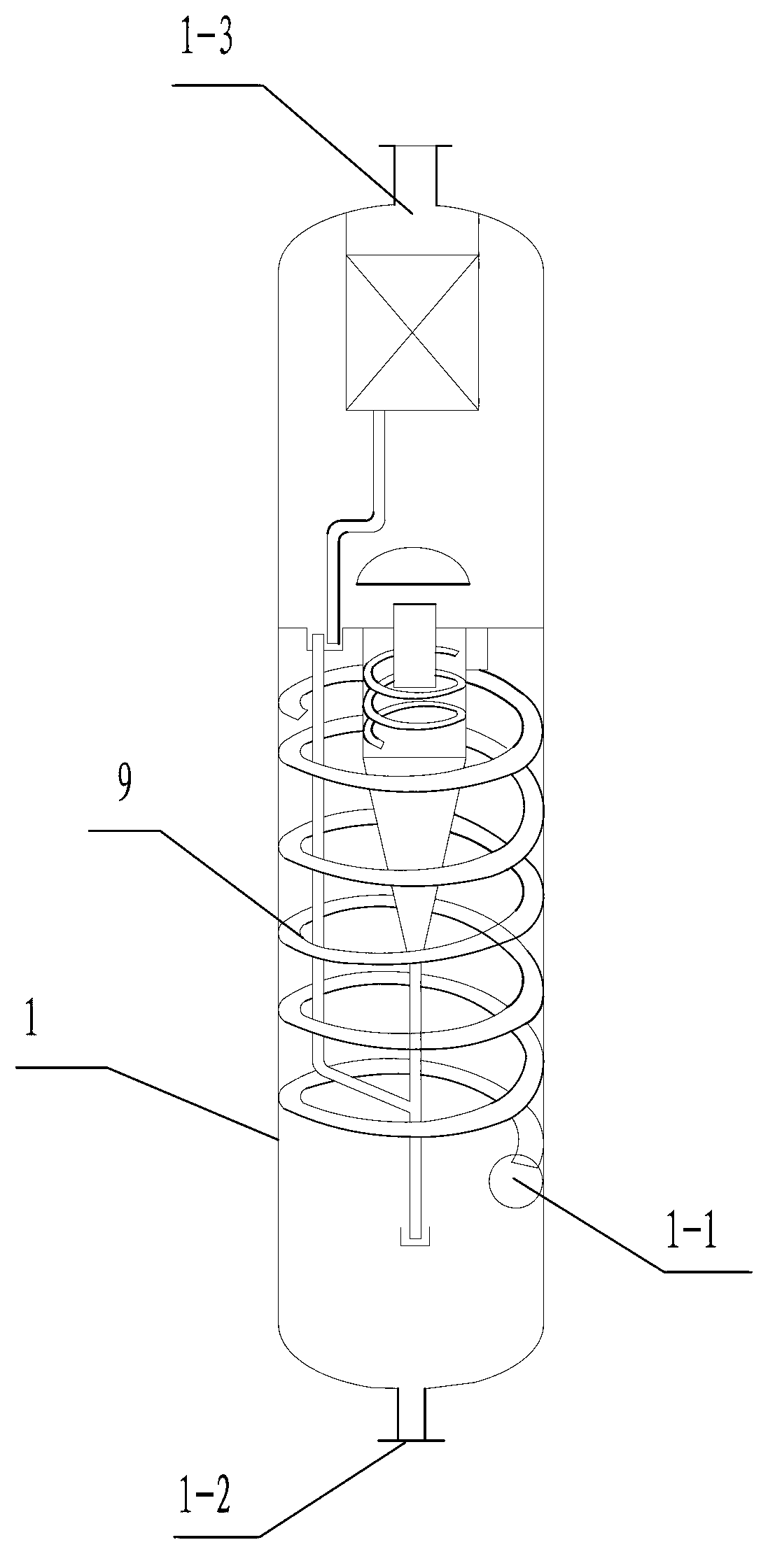

[0027] see image 3 , The structure of this example is basically the same as that of Example 1, the difference is that a second spiral deflector (9) is added in the lower chamber (2), and other structures are the same as those of Example 1. The intake air enters the casing (1) from the gas-liquid mixed phase inlet (1-1), and makes a spiral upward movement along the second spiral deflector (9), and the liquid drops in the second spiral deflector (9) ) and the inner wall of the shell coalesce and fall, and are discharged from the liquid phase separation outlet (1-2); the rotating rising airflow enters the cyclone gas-liquid separator, and the following process is the same as that of Example 1. In this example, a spiral diversion separation is added before the cyclone gas-liquid separation to further improve the separation efficiency.

[0028] The above three embodiments are used for gas-liquid separation with a small amount of liquid phase in the gas phase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com