Arrester

A spark gap and resistance technology, which is applied in the field of spark gaps, can solve the problems of increasing the operating voltage of multi-stage spark gaps, and achieve the effect of improving the characteristics of operating parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

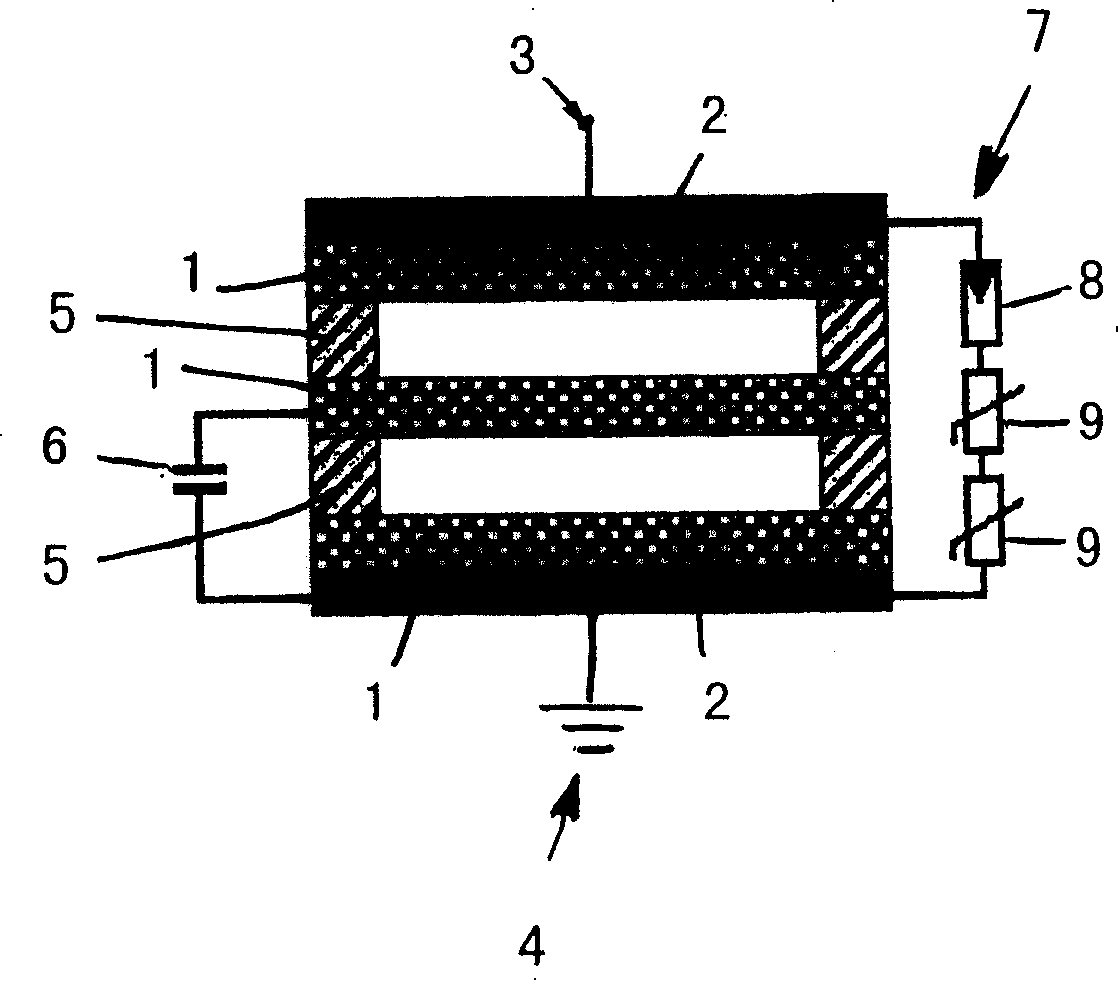

[0019] The multistage spark gap here consists of three graphite electrodes 1 , which are covered at their ends with electrode plates 2 . At 3 a phase connection is provided, and at 4 a junction with a reference potential, preferably ground potential, is provided. Teflon rings 5 are arranged between graphite electrodes 1 made of graphite as insulating elements. This is a spark gap filled with air. In this embodiment, the above-mentioned partial spark gaps are connected through a capacitor 6 except the first spark gap to be activated in the event of an overvoltage accident, and the second spark gap is connected to the common reference potential 4 through the capacitor 6 superior.

[0020] According to the invention, a multistage spark gap consisting of partial spark gaps is connected in parallel with a bypass 7 consisting of an auxiliary spark gap 8 and two varistors 9 connected in series. The auxiliary spark gap 8 here is a spark gap filled with gas, which acts faster than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com