Electric machine with box body and rotor

A technology for rotors and boxes, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., and can solve problems such as expensive shafts, stuck shafts, and troublesome ball shafts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

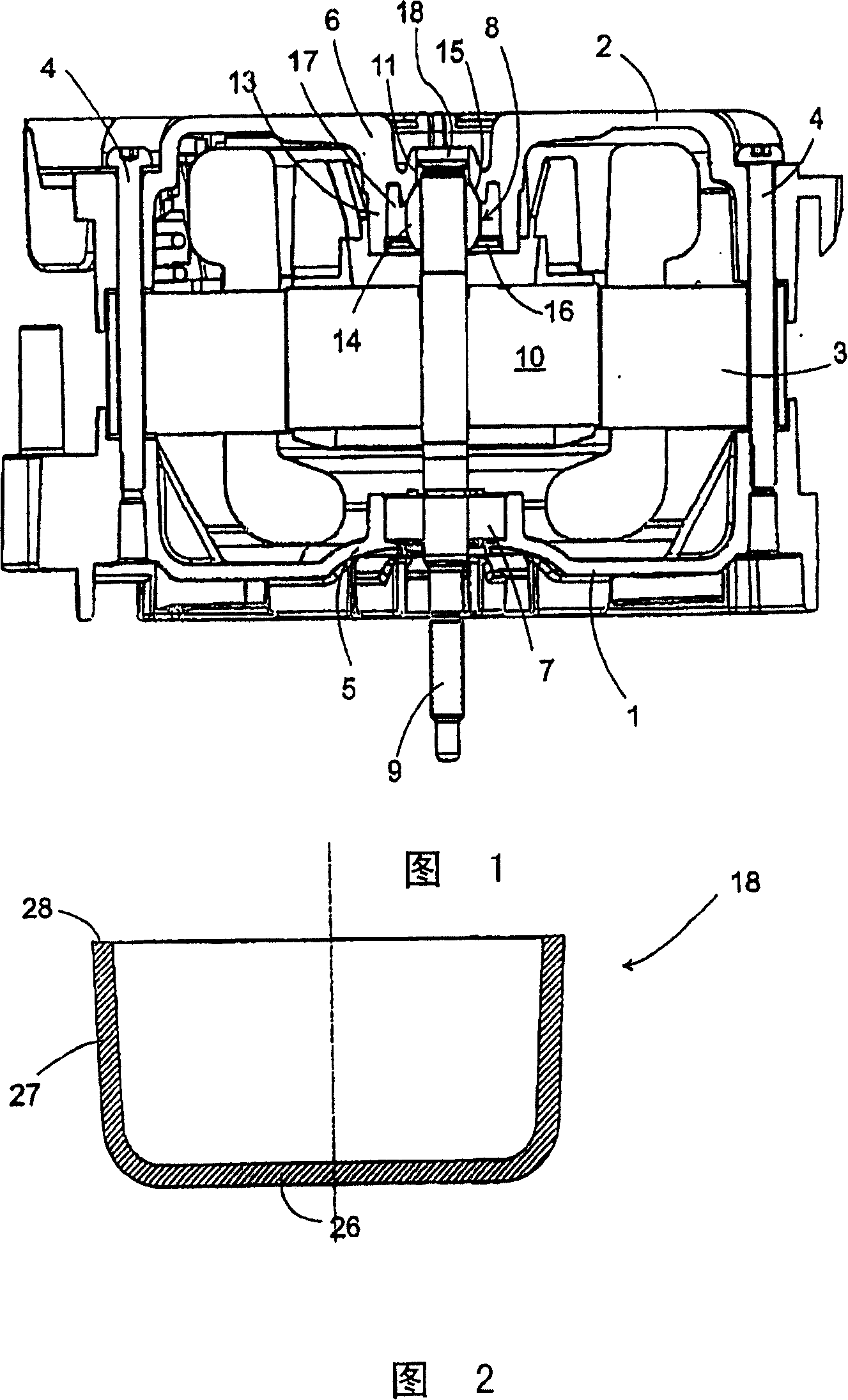

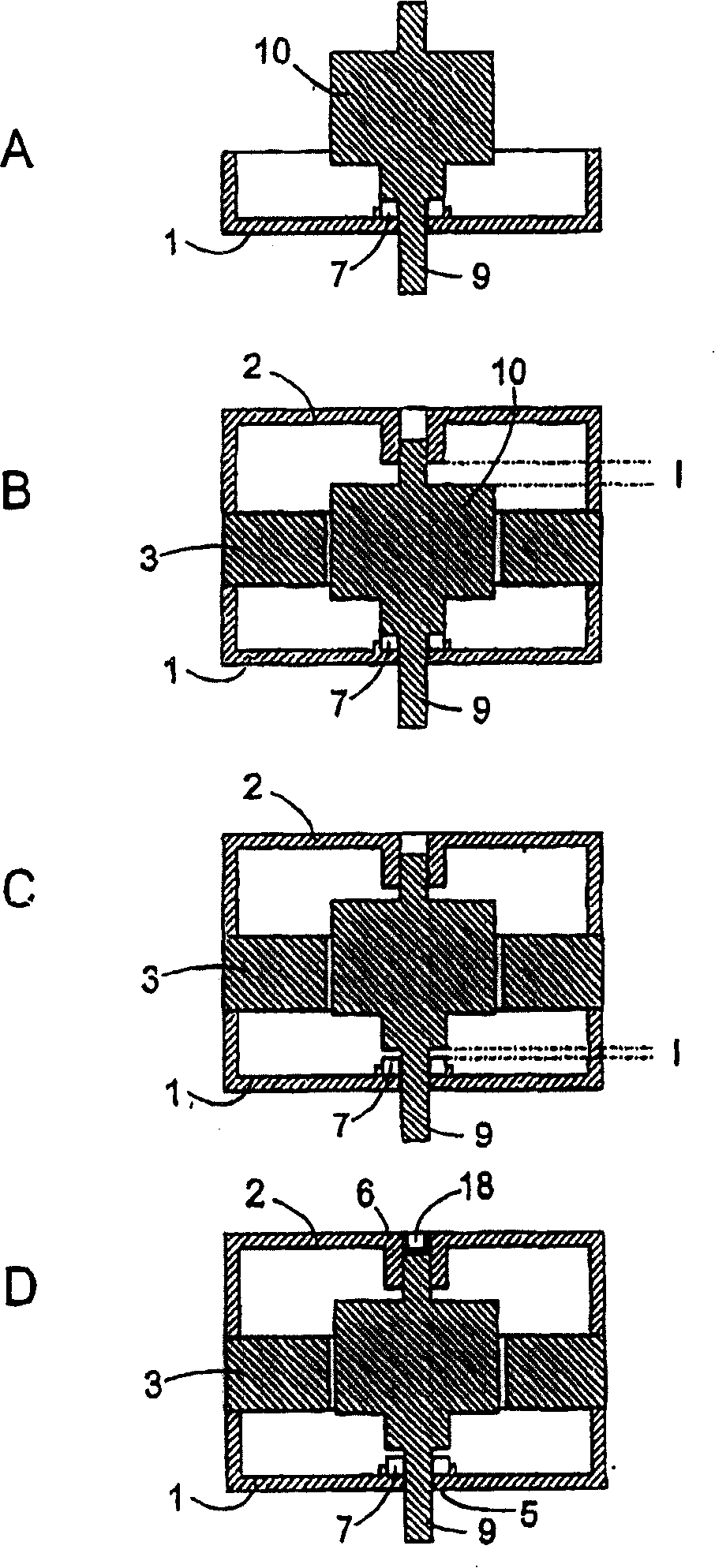

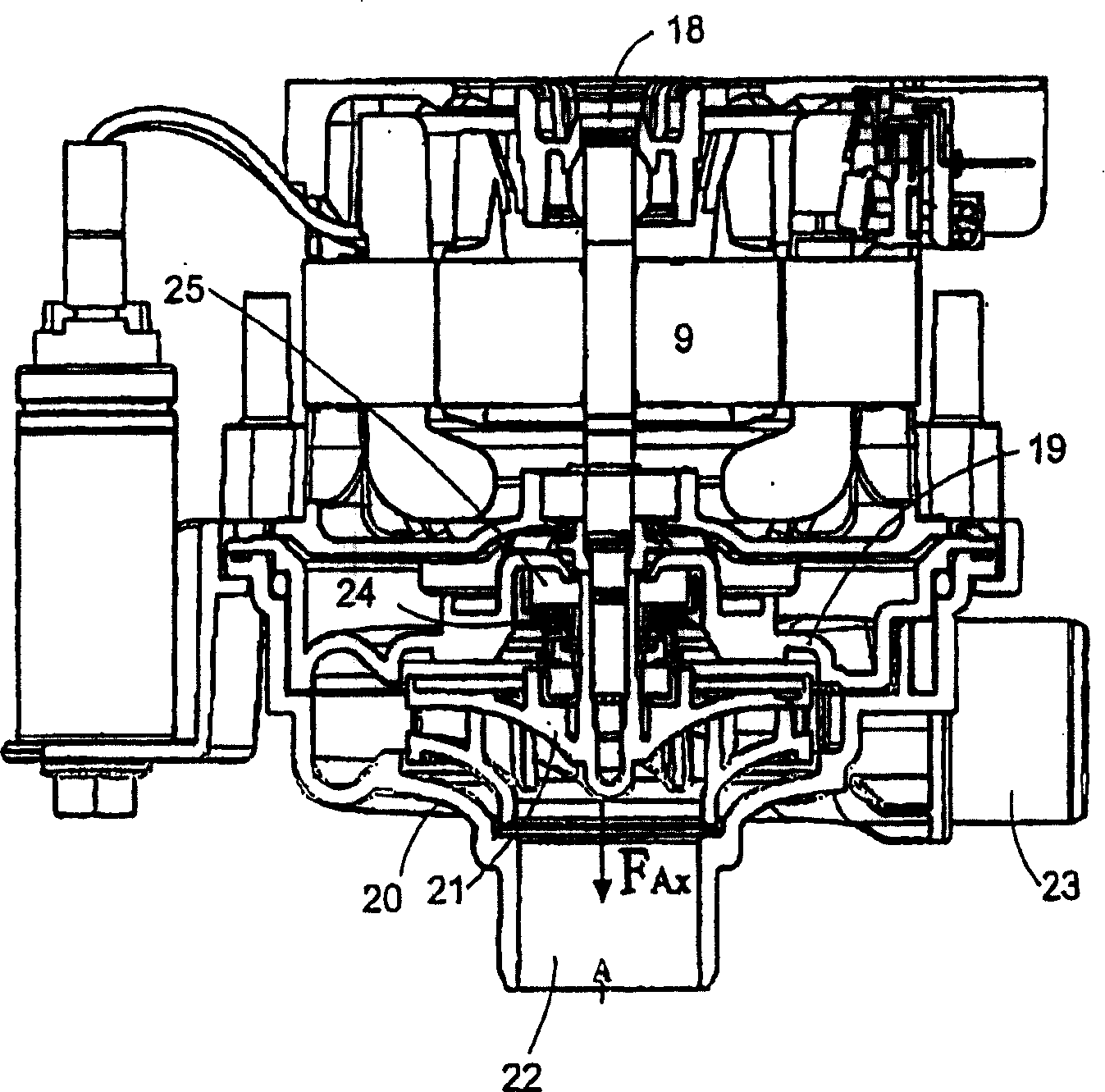

[0021] FIG. 1 shows an axial section through an electric motor according to the invention. The housing of the electric motor consists of a front housing shell 1 , a rear housing shell 2 and a stator lamination 3 . The two plastic injection-molded housing shells 1, 2 are connected by bolts 4 which extend through holes in the rear housing shell 2 and stator laminations 3 and engage in threads in the front housing shell 1 . The box shell 1,2 forms a front or rear bearing cover 5,6 respectively in its middle area, in order to accommodate a bearing 7 or 8, the bearing cover 5,6 is formed respectively, and a shaft 9 of a rotor 10 can be It is rotatably mounted in this bearing 7 or 8 . The shaft 9 extends through the front bearing cap 5 and ends in a journal protruding from the housing where the load is fixed.

[0022] The bearing 7 housed in the front bearing 5 is a ball bearing with an inner ring firmly connected to the shaft 9 and an outer ring firmly connected to the box shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com