Direct type backlight module

A backlight module, direct type technology, used in optics, nonlinear optics, instruments, etc., can solve the problems of low light uniformity and complex mechanism design, and achieve the effect of simple mechanism design and improved light uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

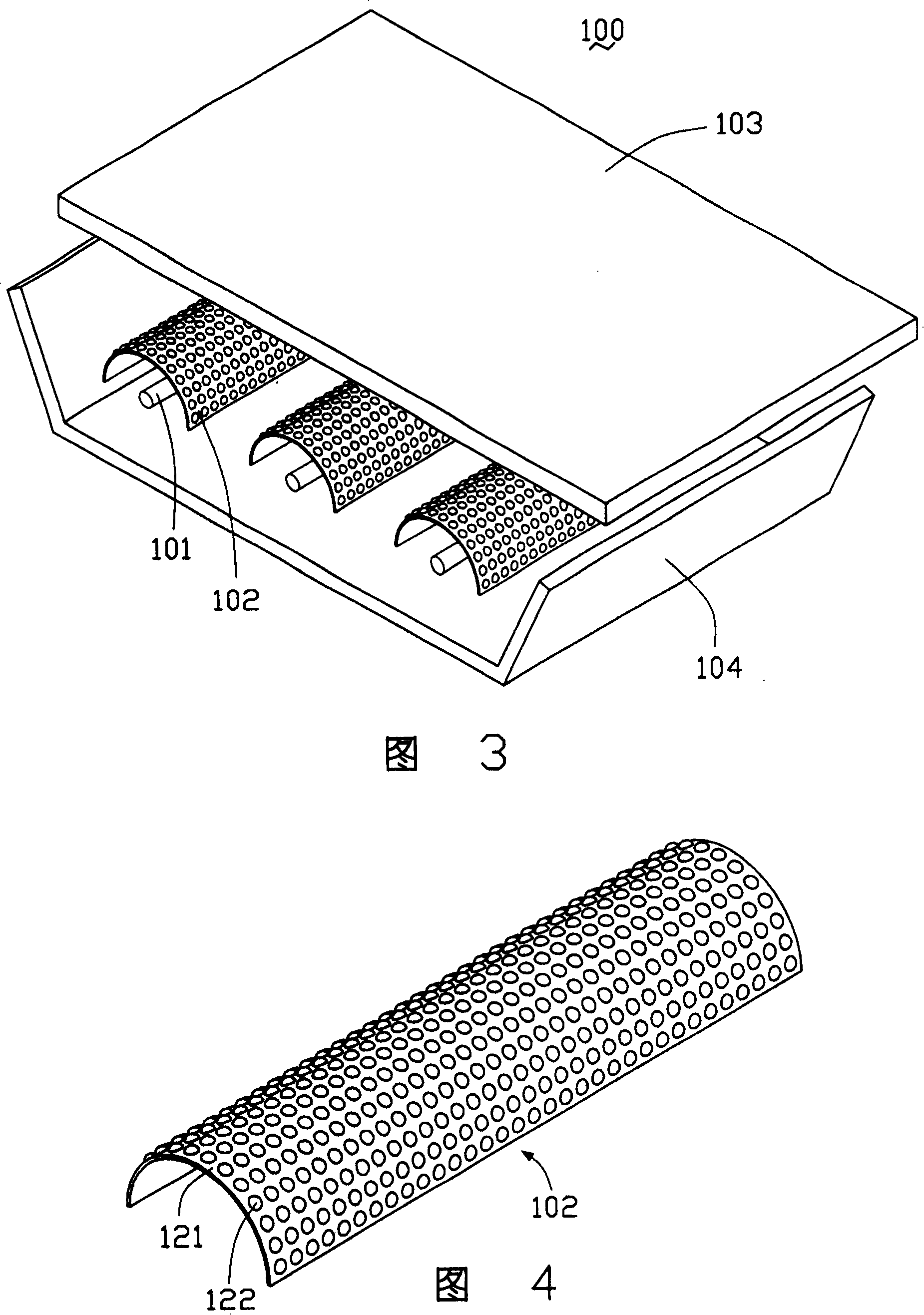

[0016] Referring to FIG. 3 , the direct type backlight module 100 of the present invention includes a plurality of lamp tubes 101 , a lamp cover 102 partially surrounding the lamp tubes 101 , a diffuser plate 103 and a reflective element 104 . The lamp tube 101 and the lamp cover 102 are located in the area defined by the reflective element 104 and the diffuser plate 103, and the lamp cover 102 is located between the lamp tube 101 and the diffuser plate 103. The light emitted by the lamp tube 101 is transmitted to the diffuser plate after being acted by the lamp cover 102. 103 and converted into a uniform plane light.

[0017] The lamp tube 101 may be a cold cathode fluorescent lamp, which has the advantages of higher brightness, higher luminous efficiency, smaller tube diameter and longer life than other light source technologies. The tube diameter of the lamp tube 101 is about 10mm, the power is about 8-29w, the life is as long as 10000hrs, and the luminous flux is about 35-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com