Nail clippers-file and its making process

A manufacturing method and technology of nail scissors, applied in metal material coating process, melt spraying, coating, etc., can solve the problems of difficult nail scissors file quality, complicated process, etc., meet the requirements of easy appearance and quality, simple process, Master the effect of appearance and quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

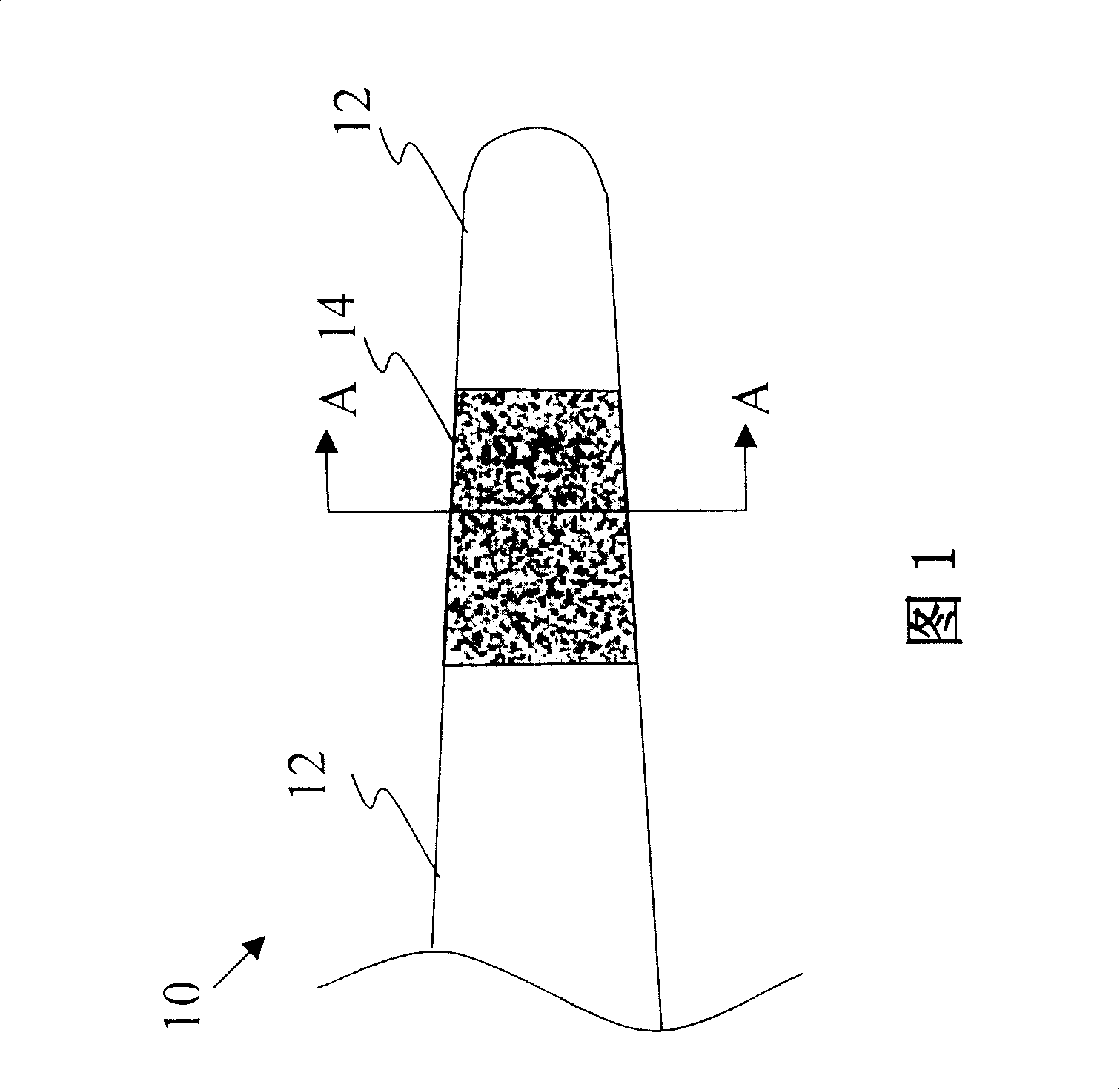

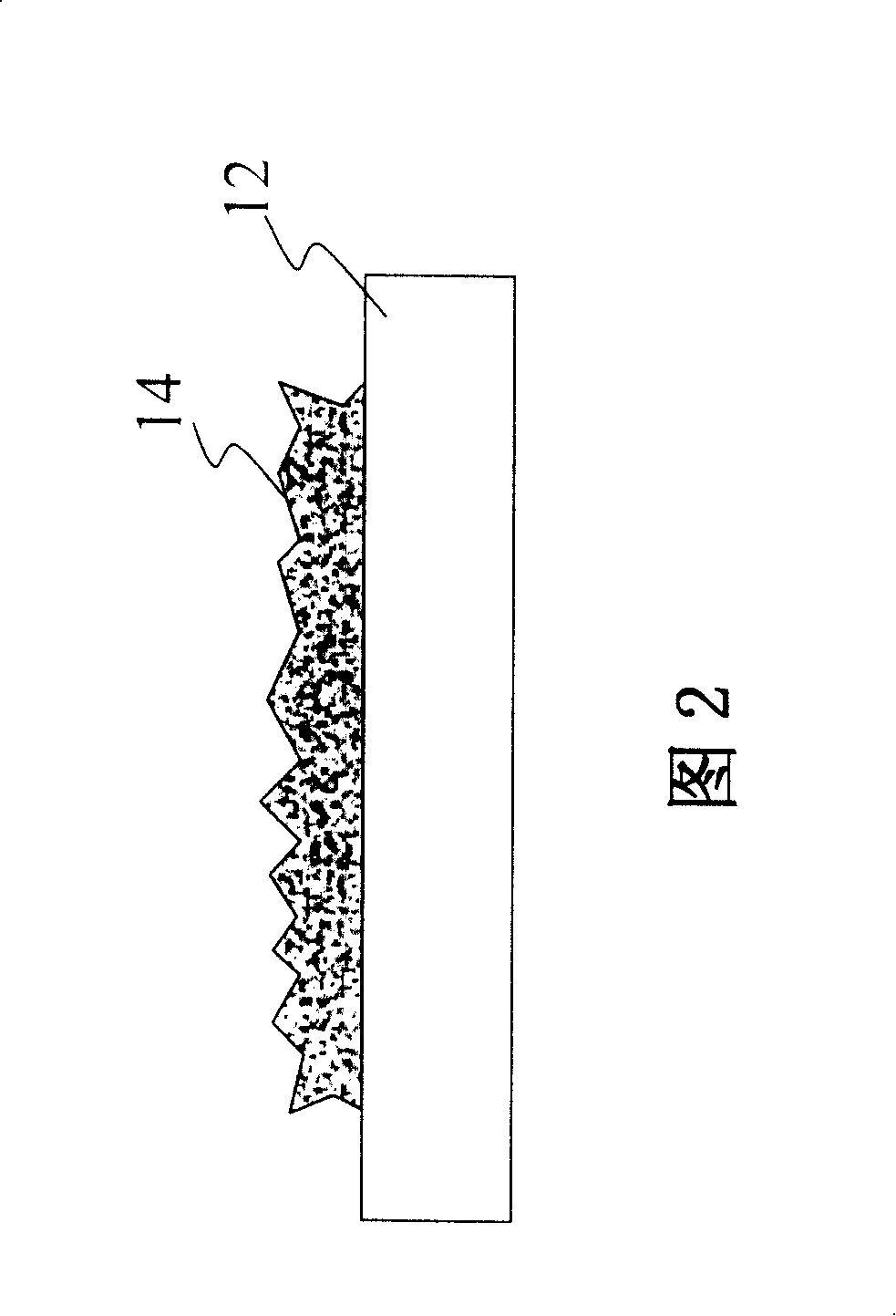

[0044] Please refer to FIG. 1 and FIG. 2 , which respectively show a partial schematic view of the nail clipper file of the present invention and a schematic cross-sectional view of the section line A-A in FIG. 1 .

[0045] The nail scissors file 10 provided by the present invention comprises a base material 12 and a coating 14 formed by spraying raw materials on the base material 12 by a thermal spraying method, and the coating 14 has a rough surface.

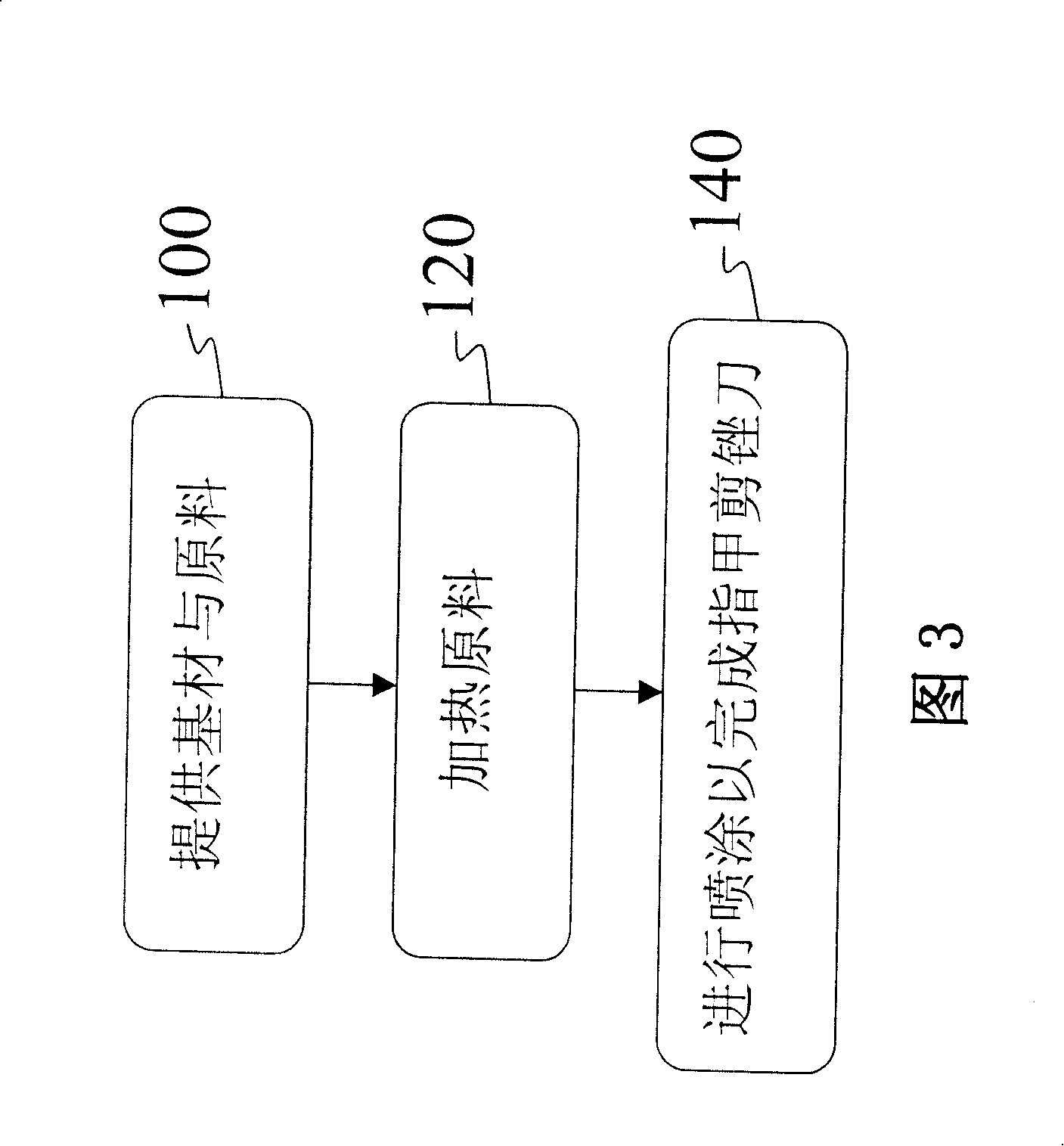

[0046] Please refer to FIG. 3 , which is a flow chart of the manufacturing method of the nail clipper file of the present invention, which mainly includes the following steps: step 100, providing a base material and a raw material, and the raw material end depends on the coating material to be sprayed; then, step 200, Heating the raw material so that the raw material is heated into a molten or semi-molten state; then, step 140, spraying to complete the nail clipper file, that is, spraying the raw material on a specific part of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com