Thermal splicing type flexible freight container

A container bag and enhanced technology, which is applied in the field of container bags, can solve problems that cannot meet the requirements of cleanliness, molding effect, production efficiency, bag body strength, UV resistance and color uniformity, unreasonable selection of raw materials, and insufficient technology. Perfect and other problems, to achieve good anti-ultraviolet ability, improve color uniformity, and fast production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0116] The second aspect of the present invention provides a method for preparing a thermally spliced container bag, which includes at least the following steps:

[0117] 1) Woven fabric: the base fabric is woven with warp and weft, and the warp to weft ratio of the base fabric is 1: (0.7~1.2);

[0118] 2) Coating: using a double-sided coating process, in step 1) the base fabric is coated with a composite film of PE and PP on both sides to obtain a finished fabric;

[0119] 3) Forming: The finished fabric obtained in step 2) is cut, and heat-sealed, spliced, and formed to obtain.

[0120] The present invention has no special restrictions on the preparation method of the warp and weft in step 1), as long as the required warp and weft can be obtained without affecting the purpose of the present invention. For example, the preparation method of warp and weft may be: extruding the raw materials for preparing the warp and weft into a film, then cutting and slitting, and finally stretchin...

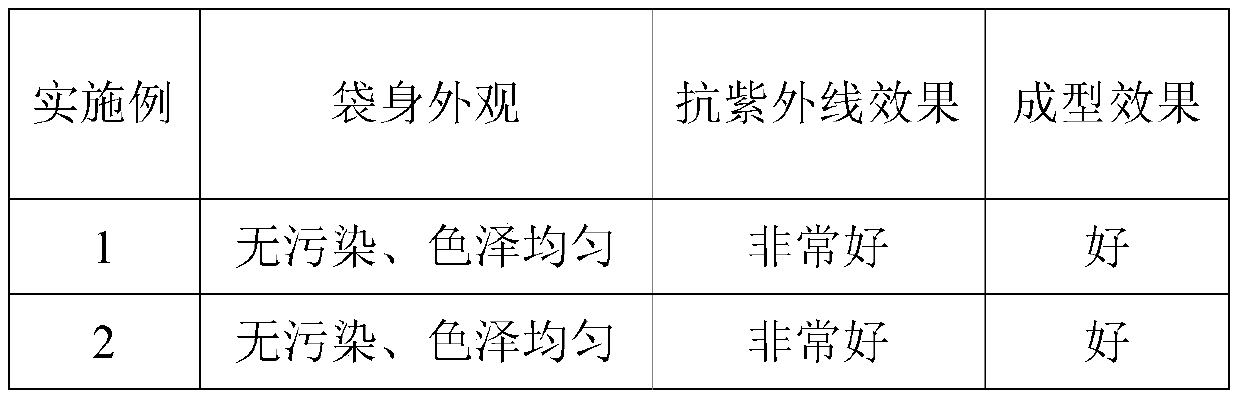

Embodiment 1

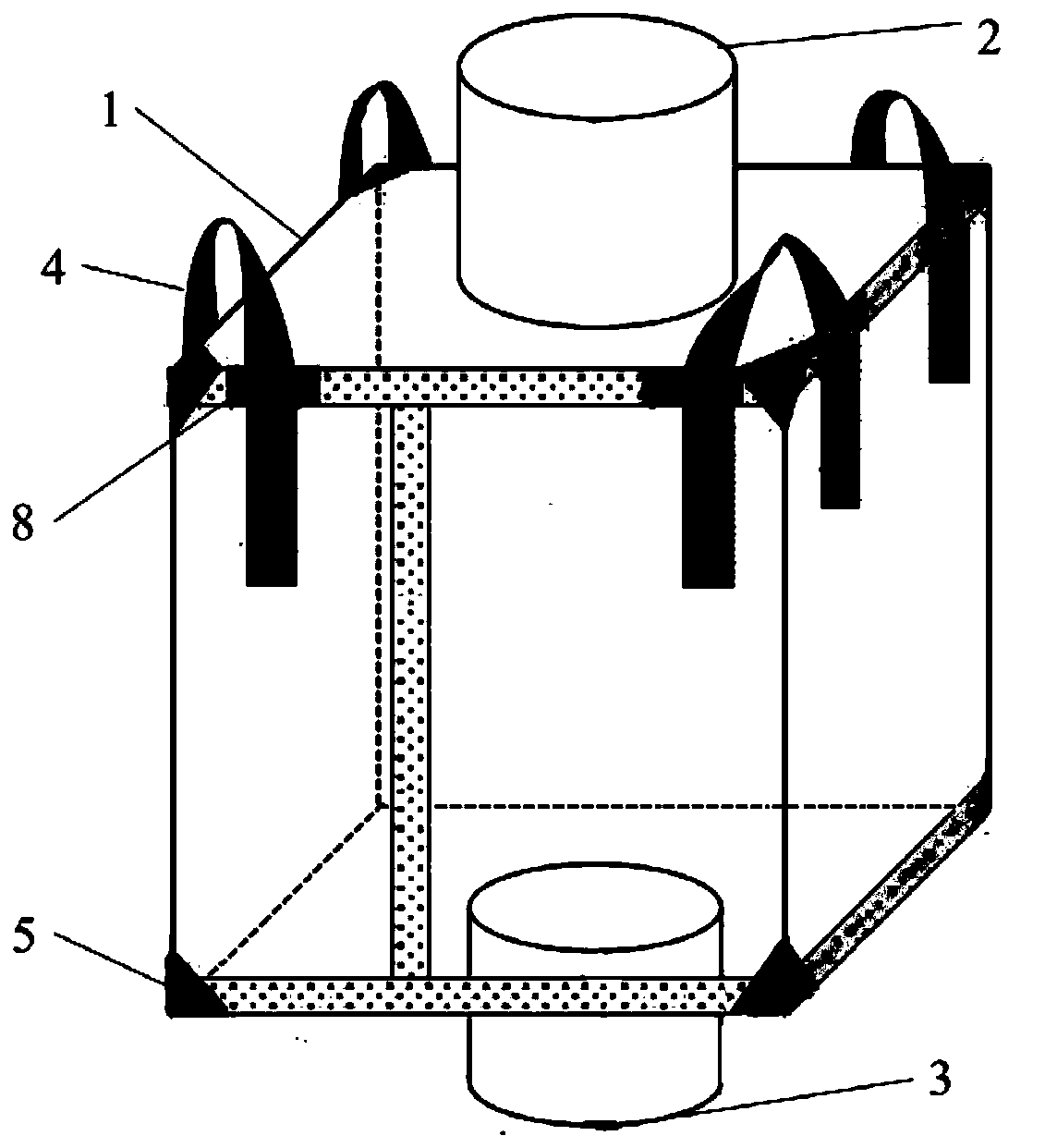

[0134] Embodiment 1 provides a thermally spliced container bag, which includes a container bag body 1, in the middle of the top and bottom of the container body 1 are provided with an inlet 2 and an outlet 3, in The four corners of the upper part of the container bag body 1 are equipped with reinforced slings 4, and the triangular intersections of the container bag body 1 are equipped with sealing triangle modules 5, and the bag body of the container bag body 1 is from The inside to outside includes a waterproof layer 6, a base cloth layer 7, and a waterproof layer 6, respectively, and the waterproof layer 6 is a composite film of PE and PP.

[0135] There are 8 sealing triangle modules 5 in total.

[0136] The sealing triangle module 5 and the container bag body 1 are connected by hot melt glue.

[0137] The hot melt adhesive is EVA hot melt adhesive.

[0138] The ratio of the raw materials PE and PP in the composite film of PE and PP is 1:4.

[0139] The raw materials for preparin...

Embodiment 2

[0160] Embodiment 2 provides a thermally spliced container bag, which includes a container bag body 1. The top middle and bottom middle positions of the container bag body 1 are respectively provided with a feed port 2 and a discharge port 3. The four corners of the upper part of the container bag body 1 are equipped with reinforced slings 4, and the triangular intersections of the container bag body 1 are equipped with sealing triangle modules 5, and the bag body of the container bag body 1 is from The inside to outside includes a waterproof layer 6, a base cloth layer 7, and a waterproof layer 6, respectively, and the waterproof layer 6 is a composite film of PE and PP.

[0161] There are 8 sealing triangle modules 5 in total.

[0162] The sealing triangle module 5 and the container bag body 1 are connected by hot melt glue.

[0163] The hot melt adhesive is EVA hot melt adhesive.

[0164] The ratio of the raw materials PE and PP in the composite film of PE and PP is 1:3.

[0165]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com