Aerator ejector

A jet device and aerator technology, applied in chemical instruments and methods, water aeration, sustainable biological treatment, etc., can solve the problem of large power consumption, inability to vary power efficiency and mixed outflow velocity, limiting aerators, etc. problems, to achieve a higher degree of oxygenation, reduce suspended debris in pool water, and increase the number of aeration times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

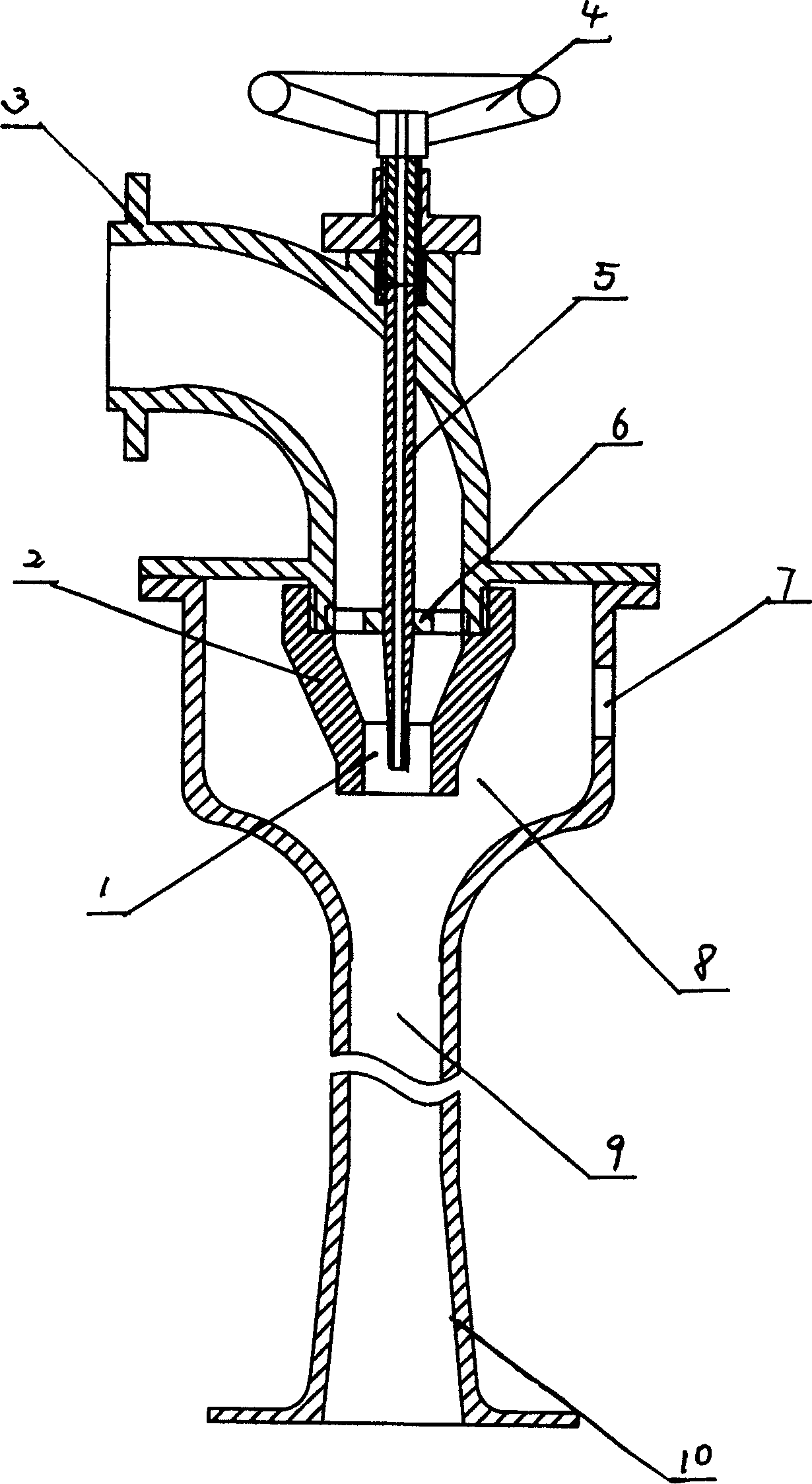

[0017] An aerator jet, which includes a suction chamber 8, a throat tube 9, and a diffusion tube 10. The suction chamber 8 has an incident water flow inlet facing the throat tube 9, and the incident water flow inlet is equipped with a nozzle 2 and the incident water flow inlet A water inlet pipe 3 is connected to the outside of the air suction chamber 8, an outer air inlet 7 is provided on the side wall of the suction chamber 8, and an adjusting pipe 5 is installed in the axial direction in the nozzle 2, and the adjusting pipe 5 is provided with an inner suction hole, The hole wall is required to be very smooth, the wall thickness of the regulating tube 5 should be able to ensure that the regulating tube is basically not bent when impacted by water flow, and the diameter and wall thickness of the effective regulating section of the regulating tube 5 located in the nozzle 1 gradually decrease.

[0018] The water inlet pipe 3 is an elbow pipe connected with the external submersible ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com