Antibacterial fabric finishing agent and its preparation method

A technology of antibacterial fabric and slurry, which is applied in fiber treatment, textiles and papermaking, etc. It can solve the problems that light-colored and pure white fabrics cannot be processed, antibacterial agents cannot be fixed stably, and antibacterial treatment cannot be directly used to achieve Good market prospect, overcoming the effect of poor fungal killing effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The preparation method of antibacterial agent refers to the preparation method disclosed in Chinese patent application 2005100041626.8, for example:

[0062] Weigh the materials respectively according to the ratio of metatitanic acid: 98% sulfuric acid (wt)=1: 2.0~3.0, first dilute 98% sulfuric acid with deionized water to 70~90%, and place it in the reactor. Finely ground, sieved through a 325-400 mesh sieve, and then added to sulfuric acid; start the mixer to carry out acidolysis reaction. The reaction temperature is controlled between 70 and 130°C, and the reaction time is controlled between 10 and 40 minutes; deionized water is measured according to the ratio of metatitanic acid: deionized water (wt) = 1:3 to 5, and added to the reactor for leaching Acid hydrolysis product, the temperature is controlled between 40 ~ 70 ℃; after filtering out the insoluble matter, the titanium solution is obtained, and its concentration is 80 ~ 210g / L (using TiO 2 meter, the same be...

Embodiment 2

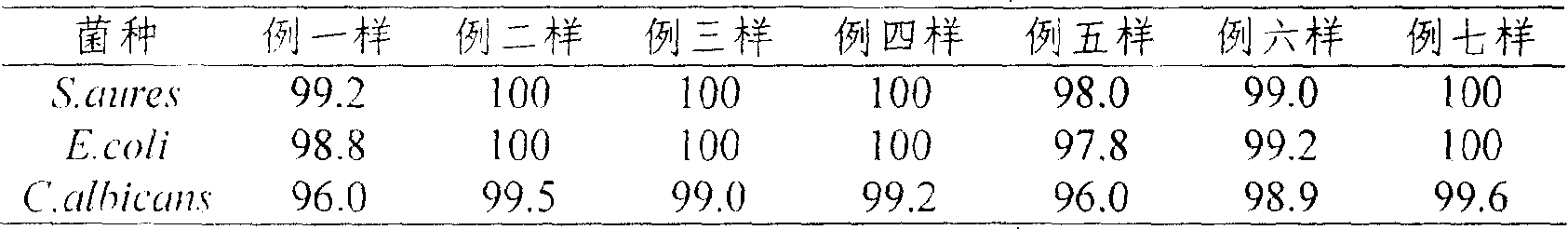

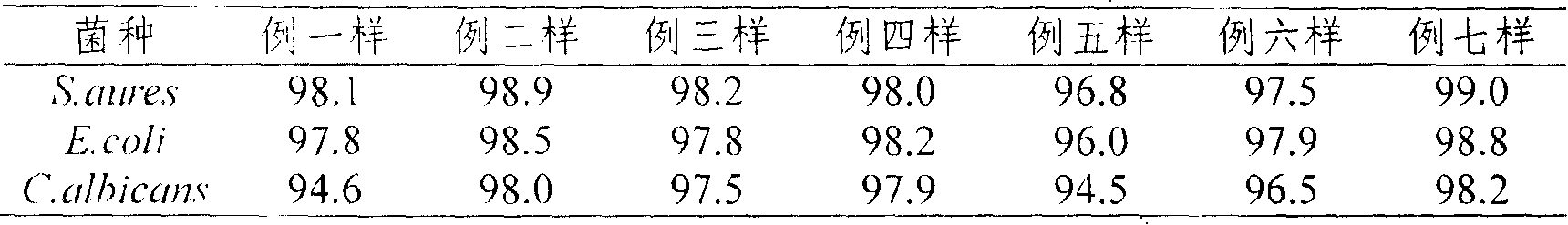

[0066] Take by weighing the prepared 2g antibacterial agent of embodiment 1 and join in 81ml water, then weigh respectively the dispersant of 0.1g (sodium hexametaphosphate: AEO-9=1: 1) and 0.12g discoloration inhibitor (benzimidazole: Add o-toluidine=1:0.3), stir and ultrasonically disperse for 30min; then add 15g of binder T-815, stir and ultrasonically disperse for 30min; then add 2.5g of thickener KT-501 and stir for 30min to obtain finishing Slurry; the prepared finishing slurry is immediately evenly coated on the prepared pure cotton cloth through the gauze (the coating amount is 4.8g / m 2 ); pre-bake at 100°C for 5 minutes, bake at 120°C for 3 minutes, take out, and cool naturally to obtain the finished product. Its antibacterial rate against Candida albicans, Escherichia coli, Staphylococcus aureus, etc. in 2 hours all reached above 99.5%. After 50 times of washing, its antibacterial rate still remains above 98.0%. The antibacterial fabric does not change color after ...

Embodiment 3

[0068] Take by weighing respectively the 2.5g antibacterial agent prepared in Example 1, the dispersant (sodium aluminate: AEO-9=1.5: 1) and 0.16g discoloration inhibitor (benzotriazole: ethoxymethylaniline) of 0.13g =1:0.4) into 77ml of water, stirred and ultrasonically dispersed for 30min; then added 18g of binder T-818 and stirred and ultrasonically dispersed for 30min; then added 2.3g of thickener KT-502 and stirred for 30min to obtain the finishing slurry ; The prepared finishing slurry is immediately evenly coated on the prepared polyester cotton cloth through the gauze (the coating amount is 5.0g / m 2 ); pre-bake at 100°C for 5 minutes, bake at 110°C for 3 minutes, take out, and cool naturally to obtain the finished product. Its antibacterial rate against Candida albicans, Escherichia coli, Staphylococcus aureus, etc. in 2 hours all reached above 99.0%. After 50 times of washing, its antibacterial rate still remains above 97.5%. The antibacterial fabric does not change...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com