Preparation method of antibacterial preservative

A technology of bactericidal preservatives and mass ratio, applied in the direction of bactericides, botanical equipment and methods, biocides, etc., can solve the problems of easy pollution in the production and use process, difficult preparation of bactericidal preservatives, and difficult cleaning of oil emulsions, etc. Achieve the effects of eliminating hemolytic toxicity, strong adhesion, and improved antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

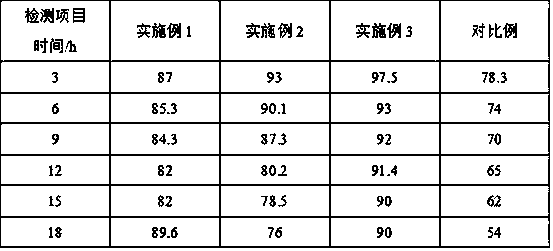

Examples

preparation example Construction

[0026] A preparation method of a bactericidal preservative, comprising the steps of:

[0027] (1) Take the transglutaminase powder and add it to the PBS buffer solution with a concentration of 0.2 mol / L at a mass ratio of 1:8, stir and mix at 30~35°C for 20~30min to obtain a stirred mixture, take the stirred mixture at 3000 r / L After centrifuging for 10 min, take the supernatant A for vacuum filtration, take the filtrate for dialysis, and freeze-dry to obtain dry powder A for future use;

[0028] (2) Take sulfur and add sodium methoxide and methanol at a mass ratio of 6:11:25~20, stir and mix at -3~-4°C for 1~2h, then add benzyl chloride with 50~60% methanol mass, and heat up to 75 Keep at ~80°C for 12~15h, cool down, filter with suction, take the filtrate a and distill it under reduced pressure, take the vacuum distillate a according to the mass ratio of 1:10:15, add deionized water and ether to mix, let it stand, and collect the supernatant B. Rotary evaporation to obtain r...

Embodiment 1

[0033] Transglutaminase powder: purchased from Wuhan Huashun Biotechnology Co., Ltd.

[0034] A preparation method of a bactericidal preservative, comprising the steps of:

[0035] (1) Take transglutaminase powder and add it to PBS buffer solution with a concentration of 0.2 mol / L at a mass ratio of 1:8, stir and mix at 30°C for 20 minutes to obtain a stirred mixture, take the stirred mixture and centrifuge at 3000 r / min for 10 minutes , take supernatant A for vacuum filtration, take the filtrate for dialysis, and freeze-dry to obtain dry powder A for subsequent use;

[0036] (2) Take sulfur and add sodium methoxide and methanol at a mass ratio of 6:11:25, stir and mix at -3°C for 1 hour, then add benzyl chloride with 50% methanol mass, heat up to 75°C and keep for 12 hours, cool, and filter with suction. Take the suction filtrate a for vacuum distillation, take the vacuum distillate a, add deionized water and diethyl ether in a mass ratio of 1:10:15, mix, let it stand, colle...

Embodiment 2

[0041] Transglutaminase powder: purchased from Wuhan Huashun Biotechnology Co., Ltd.

[0042] A preparation method of a bactericidal preservative, comprising the steps of:

[0043] (1) Take transglutaminase powder and add it to PBS buffer solution with a concentration of 0.2 mol / L at a mass ratio of 1:8, stir and mix at 32°C for 22 minutes to obtain a stirred mixture, take the stirred mixture and centrifuge at 3000 r / min for 10 minutes , take supernatant A for vacuum filtration, take the filtrate for dialysis, and freeze-dry to obtain dry powder A for subsequent use;

[0044] (2) Take sulfur and add sodium methoxide and methanol at a mass ratio of 6:11:22, stir and mix at -3°C for 1 hour, then add benzyl chloride with 52% methanol mass, raise the temperature to 77°C and keep for 13 hours, cool, and filter with suction. Take the suction filtrate a for vacuum distillation, take the vacuum distillate a, add deionized water and diethyl ether in a mass ratio of 1:10:15, mix, let i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com